ASAP 2020 PLUS

Accelerated Surface Area and Porosity

- Hi resolution surface area and porosity analyzer

- Independent preparation and analysis instrument in a single cabinet

- Ideal for research, development, and quality control applications

The ASAP 2020 Plus is a high-performance adsorption analyzer for measuring surface area, pore size, and pore volume of powders and porous materials. Standard methods or user customized protocols can be used to characterize adsorbents, catalysts, zeolites, MOFs, APIs, excipients, and a wide variety of porous and non-porous materials. The ASAP 2020 Plus is ideally suited for gas adsorption analysis of microporous (0.35 to 2nm) and mesoporous (2 to 50nm) materials and delivers superior accuracy, resolution and data reduction. A vapor sorption option can be added to the ASAP 2020 Plus to extend the analysis range of the ASAP 2020 Plus physisorption.

A chemisorption option extends the application range of the ASAP 2020 plus to both physical and chemical adsorption for characterizing the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

Features and Benefits:

Design Versatility

Design Versatility

- Two independent vacuum systems permit simultaneous preparation of two samples while analyzing another. This maximizes your personnel productivity and your return on time invested

- Continuous saturation pressure (Po) monitoring and unique Isothermal Jacket Cold Zone Control provide a stable thermal environment for both saturation pressure and adsorption. Spend time on results instead of controlling temperature variations

- The ASAP 2020 Plus is configurable with many optional accessories to meet your specific analytical requirements

Advanced Capabilities through Optional Configurations

Advanced Capabilities through Optional Configurations

The ASAP 2020 Plus can be configured to your specific needs with the option of upgrading at a later date as your analytical requirements change, maximizing the utility of this instrument and your investment.

Choose from low surface area, to heated vapor, to micropore capability. Add a cryostat, an external detector, or configure the unit for enhanced chemical resistance when working with aggressive vapors. The ASAP 2020 Plus permits one instrument to accommodate almost any surface characterization need in your lab.

A chemisorption option extends the application range of the ASAP 2020 plus to both physical and chemical adsorption for characterizing the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

Unique and Innovative Isothermal Jacket Cold Zone Control

Unique and Innovative Isothermal Jacket Cold Zone Control

Isothermal jackets are guaranteed for the life of the instrument and ensure a constant thermal profile along the full length of both the sample and saturation pressure (Po) tubes.

Specifications

| Analysis | ||

| Physisorption | Chemisorption | |

| Analysis Range | 1.3 x 10-9 to 1.0 P/P0 | 1 x 10-6 to 900 torr |

| Roughing Pump | 4 stage diaphragm | 4 stage diaphragm |

| Krypton Analysis | optional | standard |

| Minimum Measurable Surface Area | Standard 0.01 m2 /g 0.01 m2 /g Krypton 0.0005 m2 /g 0.0005 m2 /g |

|

| Physisorption | Chemisorption | |

| Adsorptive Gas Inlets | 6 | 12 standard; optional up to 16 |

| Vapor Sorption Option | Included, optional heated vapor source | Included, optional heated vapor source |

| Furnace | N/A | Ambient to 1100°C |

| Programmable from 0.1 to 50 °C/min | ||

| Degas | 2 | 2 |

| Pressure Transducer System | 1000 torr 0.12% reading | 1000 torr 0.12% reading |

| Transducer Accuracy | 10 torr 0.12% reading | 10 torr 0.12% reading |

| 0.1 torr 0.15% reading | 0.1 torr 0.15% reading | |

| Cryogen | ||

| Physisorption | Chemisorption | |

| Cryogen Dewar | 3.2 L, unlimited holding time with refill during analysis | 3.2 L, unlimited holding time with refill during analysis |

| Cryogen Free Space Control | Isothermal Jacket | Isothermal Jacket |

| Reports | ||

| Data Analysis for Texture and Active Area | BET Surface Area, t-Plot, BJH, Horvath-Kawazoe, Saito-Foley, Cheng-Yang, DFT, NLFT, and others | Metal dispersion, Metal surface area, Crystallite Size |

| Advanced Modeling | Heat of Adsorption, GAB, Sips, Toth, dissociative Langmuir, Redlich-Peterson, Virial Equation, AutoFit BET | |

| Instrument Operation Dashboard | Dashboard permits real-time monitoring of critical parameters | |

* Due to continuous improvements, specifications are subject to change without notice.

Technology & Configuration

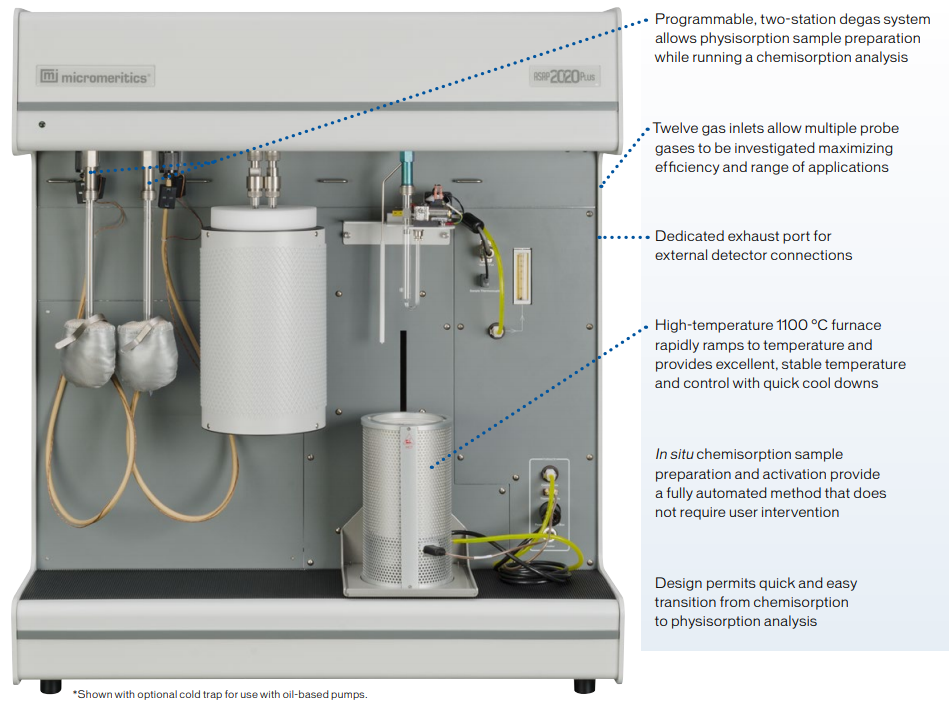

ASAP 2020 PLUS - Chemisorption

ASAP 2020 PLUS – Chemisorption

The ASAP 2020 Plus Chemisorption option permits you to obtain valuable information about the physical and chemical properties of your catalyst, catalyst support, adsorbents, and other materials. Its unique design provides a high level of system cleanliness to permit low-pressure chemisorption isotherms.

Designed For Expanding Needs

- Micropore Option – Includes a 0.1-mmHg transducer and a high vacuum pump. This system delivers accurate porosity data on pores between 0.35 and 3 nanometers and provides a comprehensive selection of micropore reports.

- Vapor Adsorption Option – Includes optional vapor accessories.

- Cold Trap Option – Cold trap option available for your specific application.

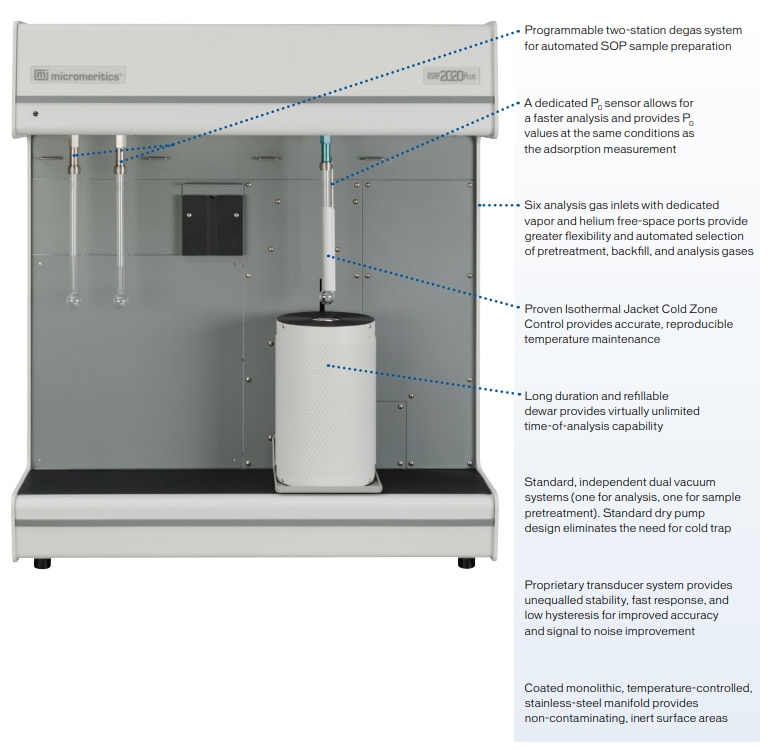

ASAP 2020 PLUS - Physisorption

ASAP 2020 PLUS – Physisorption

Research grade results in a customer-configurable instrument to meet a wide variety of applications for mesopore, micropore, and low surface area applications.

Designed For Expanding Needs

- Micropore Option – Includes a 0.1-mmHg transducer and a high vacuum pump. This system delivers accurate porosity data on pores between 0.35 and 3 nanometers and provides a comprehensive selection of micropore reports.

- Vapor Adsorption Option – Includes optional vapor accessories.

- Cold Trap Option – Cold trap option available for your specific application.

Application

![]() Pharmaceuticals: Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bio-availability.

Pharmaceuticals: Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bio-availability.

![]() Ceramics: Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

Ceramics: Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

![]() Adsorbents: Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

Adsorbents: Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

![]() Activated Carbons: Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in wastewater management.

Activated Carbons: Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in wastewater management.

![]() Carbon Black: The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production.

Carbon Black: The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production.

![]() Fuel Cells: Fuel cell electrodes require high surface area with controlled porosity to produce optimum power density

Fuel Cells: Fuel cell electrodes require high surface area with controlled porosity to produce optimum power density

![]() Catalysts: The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

Catalysts: The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

![]() Paints and Coatings: The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness,solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

Paints and Coatings: The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness,solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

![]() Projectile Propellant: The burn rate of propellants is a function of surface area too high a rate can be dangerous; too low a rate can cause malfunction and inaccuracy.

Projectile Propellant: The burn rate of propellants is a function of surface area too high a rate can be dangerous; too low a rate can cause malfunction and inaccuracy.

![]() Medical Implants: Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

Medical Implants: Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

![]() Electronics: By selecting high surface area material with carefully designed pore networks, manufacturers of super-capacitors can minimize the use of costly raw materials while providing more exposed surface area for storage of charge.

Electronics: By selecting high surface area material with carefully designed pore networks, manufacturers of super-capacitors can minimize the use of costly raw materials while providing more exposed surface area for storage of charge.

![]() Cosmetics: Surface area is often used by cosmetic manufacturers as a predictor of particle size when agglomeration tendencies of the fine powders make analysis with a particle-sizing instrument difficult.

Cosmetics: Surface area is often used by cosmetic manufacturers as a predictor of particle size when agglomeration tendencies of the fine powders make analysis with a particle-sizing instrument difficult.

![]() Aerospace: Surface area and porosity of heat shields and insulating materials affect weight and function.

Aerospace: Surface area and porosity of heat shields and insulating materials affect weight and function.

![]() Geoscience: Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

Geoscience: Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

![]() Nanotubes: Nanotube surface area and microporosity are used to predict the capacity of a material to store hydrogen.

Nanotubes: Nanotube surface area and microporosity are used to predict the capacity of a material to store hydrogen.

![]() More Applications:

More Applications:

- Adhesives

- Alloys

- Abrasives

- Carbonates

- Cements

- Clays

- Detergents

- Fibers

- Films

- Fertilizers

- Filters

- Glass

- Food Additives

- Graphite

- Minerals

- Paper

- Polishing Compounds

- Polymers

- Resins

- Soils and Sediments

Accessories

Quote AccessoriesSoftware and Reporting Versatility

ASAP 2020 Software Features The easy-to-use ASAP 2020 software utilizes a Windows® interface that includes Wizards and applications to help plan, launch, and control the analysis. You can collect, organize, archive and reduce raw data, and store standardized sample information and analysis conditions for easy access during later applications.

Finished reports may be generated to screen, paper, or data transfer channels. Features include cut-and-paste graphics, scalable-and-editable graphs, and customizable reports. Additional capabilities include:

- Degas temperature profiles and treatment time data are integrated with the sample file for future reference and verification of SOP compliance.

- The Instrument Schematic screen displays the instrument’s current operating status, including the real-time isotherm, and allows the operator to assume manual control of the instrument if desired.

- Overlays can be used to compare.

- Exportable data tables provide for merging and comparing data from other sources in a unified single spreadsheet file.

- Three modes of gas dosing routines provide effective choices to ensure maximum speed with full accuracy for samples with widely differing isotherm shapes.

- The patented Smart Dosing™ routine actually learns about the sample’s potential to adsorb gas and adjusts the adsorptive doses accordingly. This helps prevent over-dosing the sample and obscuring porosity information.

- The user can enter any reference isotherm into the system by way of a data file or table. This isotherm can be used in place of the pre-programmed thickness curves when calculating thickness for t-Plots, s (Alpha-S) plots, and BJH pore size distribution. The reference isotherm can also be overlaid with other plotted data for comparisons.

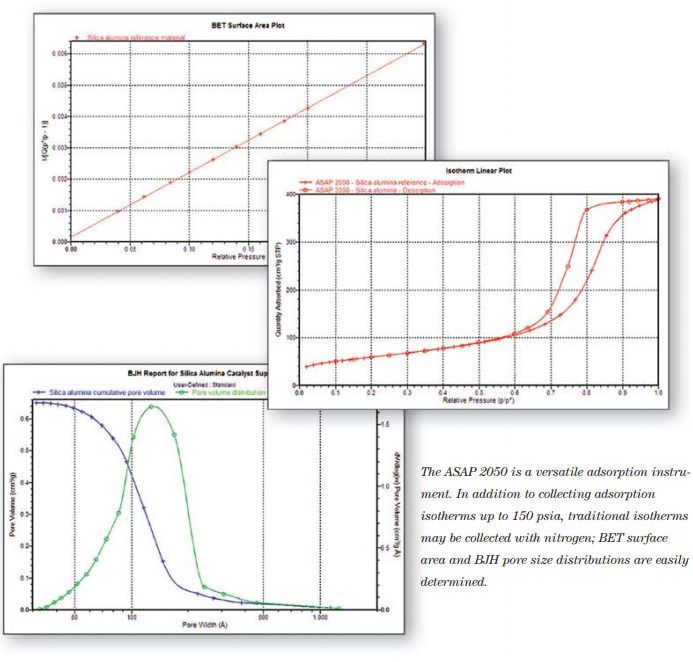

Analyses and Reports

The ASAP 2020 includes powerful data reduction software to provide a variety of easy-to-interpret report options. This allows tremendous flexibility in the selection of analysis constants to best fit your specific application. All ASAP models have the capability to collect data over a prescribed segment of the pressure range, or to perform adsorption and desorption analyses over the entire pressure range, providing extensive surface area and porosity information.

The ASAP 2020 model includes:

- Repetitive Isotherm Cycling

- DFT (Density Functional Theory)

- Single- and Multipoint BET (Brunauer, Emmett, and Teller) surface area

- Langmuir surface area

- Temkin and Freundlich isotherm analyses

- Pore volume and pore area distributions in the mesopore and macropore ranges by the BJH (Barrett, Joyner, and Halenda) method using a variety of thickness equations including user-defined, standard

isotherm - Pore volume and total pore volume in a user-defined pore size range

- F-Ratio plots that illustrate the difference between theoretical and experimental isotherm data

- Heat of Adsorption

ASAP 2020 Resources

Application Notes

- Determining Free-Space Values for ASAP Series Micropore Analyses

- Helium Effects on ASAP Series Micropore Analyses

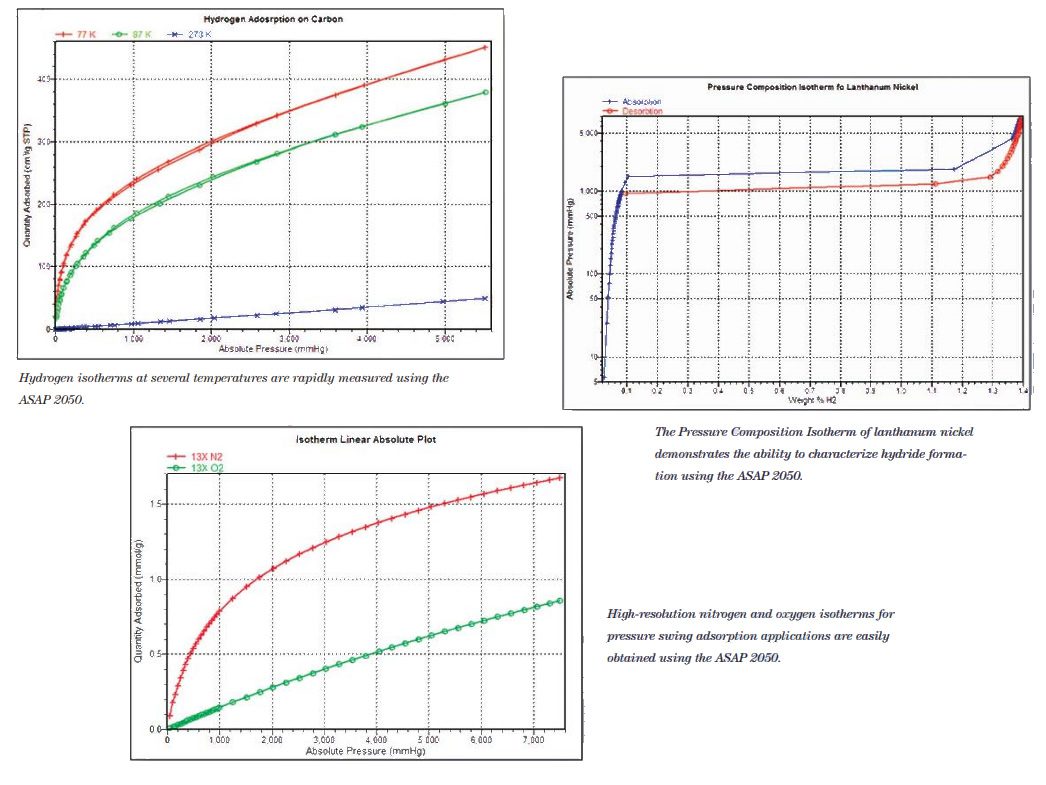

- Using the ASAP 2020 for Determining the Hydrogen Adsorption Capacity of Powders and Porous Materials

Standard Methods

- ASTM D3908 Standard Test Method for Hydrogen Chemisorption on Supported Platinum Catalysts by Volumetric Vacuum Method

- ASTM D4824 Standard Test Method for Determination of Catalyst Acidity by Ammonia Chemisorption

- WK61828 Carbon Monoxide on Supported Platinum on Alumina Catalysts using Manometric Method

- WK71859 Carbon Monoxide Chemisorption on Supported Platinum on Alumina Catalysts using Static Vacuum Method

- ASTM D4780 Standard Test Method for Determination of Low Surface Area of Catalysts and Catalyst Carriers by Multipoint Krypton Adsorption

- ASTM E2864 Standard Test Method for Measurement of Airborne Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers using Krypton Gas Adsorption

- ISO 15901-3 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 3: ANALYSIS OF MICROPORES BY GAS ADSORPTION

- ASTM D5604 Standard Test Methods for Precipitated Silica—Surface Area by Single Point B.E.T. Nitrogen Adsorption

- ISO 4652 RUBBER COMPOUNDING INGREDIENTS — CARBON BLACK — DETERMINATION OF SPECIFIC SURFACE AREA BY NITROGEN ADSORPTION METHODS — SINGLE-POINT PROCEDURES

- ISO 9277 DETERMINATION OF THE SPECIFIC SURFACE AREA OF SOLIDS BY GAS ADSORPTION — BET METHOD

- ASTM B922 Standard Test Method for Metal Powder Specific Surface Area by Physical Adsorption

- ASTM C1069 Standard Test Method for Specific Surface Area of Alumina or Quartz by Nitrogen Adsorption

- ASTM C1274 Standard Test Method for Advanced Ceramic Specific Surface Area by Physical Adsorption

- ASTM D1993 Standard Test Method for Precipitated Silica-Surface Area by Multipoint BET Nitrogen Adsorption

- ASTM D3663 Standard Test Method for Surface Area of Catalysts and Catalyst Carriers

- ASTM D4222 Standard Test Method for Determination of Nitrogen Adsorption and Desorption Isotherms of Catalysts and Catalyst Carriers by Static Volumetric Measurements

- ASTM D4365 Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

- ASTM D4641 Standard Practice for Calculation of Pore Size Distributions of Catalysts and Catalyst Carriers from Nitrogen Desorption Isotherms

- ASTM D6556 Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen Adsorption

- ASTM D8325 Standard Guide for Evaluation of Nuclear Graphite Surface Area and Porosity by Gas Adsorption Measurements

- ISO 12800 NUCLEAR FUEL TECHNOLOGY — GUIDELINES ON THE MEASUREMENT OF THE SPECIFIC SURFACE AREA OF URANIUM OXIDE POWDERS BY THE BET METHOD

- ISO 15901-2 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 2: ANALYSIS OF MESOPORES AND MACROPORES BY GAS ADSORPTION

- ISO 18757 FINE CERAMICS (ADVANCED CERAMICS, ADVANCED TECHNICAL CERAMICS) — DETERMINATION OF SPECIFIC SURFACE AREA OF CERAMIC POWDERS BY GAS ADSORPTION USING THE BET METHOD

- ISO 18852 RUBBER COMPOUNDING INGREDIENTS — DETERMINATION OF MULTIPOINT NITROGEN SURFACE AREA (NSA) AND STATISTICAL THICKNESS SURFACE AREA (STSA)

- USP <846> Specific Surface Area

- ASTM C110 Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone