ASAP 2460 & 2425

Surface Area & Porosimetry System

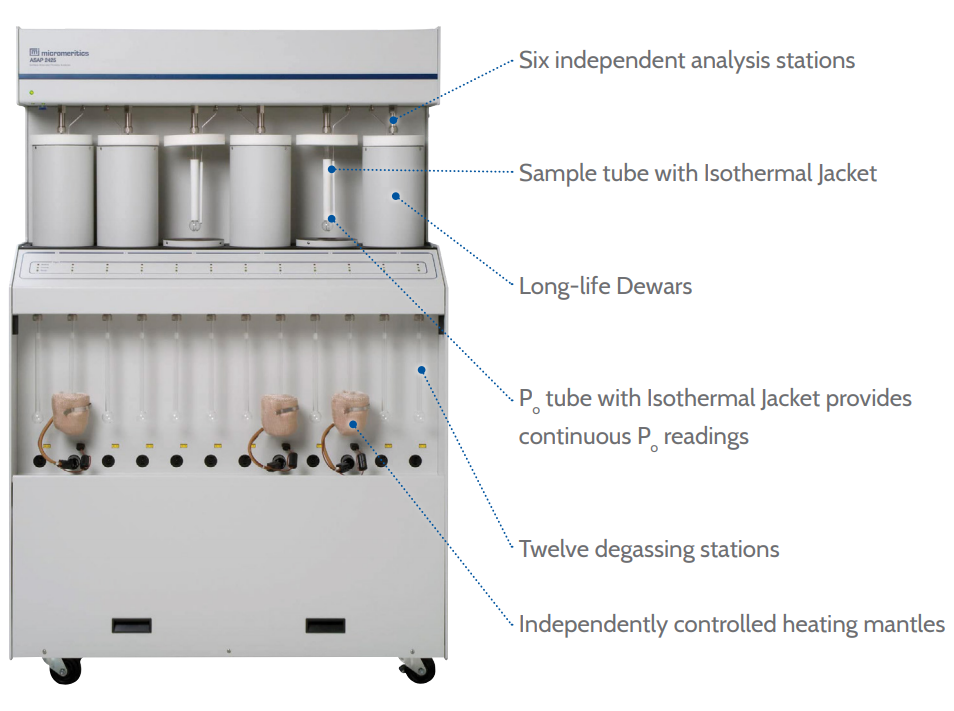

- Six independently operated analysis ports

- Long-duration Dewars and Micromeritics Isothermal Jackets

- The high-capacity Dewar

Analytical Versatility With Superior Throughput

Surface area and porosity are important physical properties that influence the quality and utility of many materials and products. Therefore it is critically important that these characteristics be accurately determined and controlled. Likewise, knowledge of surface area and especially porosity often are important properties in understanding the formation, structure, and potential application of many natural materials.

High Performance and High Sample Throughput. The automated Micromeritics® ASAP® 2425 surface area and porosimetry system is designed to help busy laboratories expand their workflow while providing highly accurate and precise surface area and porosimetry data. High performance, versatile analysis, and sample preparation systems are included in the same instrument.

Features and Benefits:

- Fully automated analyses

- High throughput with six independent analysis stations

- Each analysis port has a dedicated analysis and Po pressure transducer

- Twelve independently controlled degas ports

- Evacuation rate precisely regulated by a servo valve

- BET surface area measurements in as little as 1 hour

- Dosing options of maximum volume increment or dosing over specified pressure ranges

- Entered or calculated analysis temperature

- Equilibration option allows user to specify equilibration times for different parts of the isotherm

- Low surface area option with five independent analysis ports

Specifications

ASAP 2425 Specifications

ASAP 2425 Specifications

Electrical

| Voltage | 100/115/230 VAC (± 10%) |

| Frequency | 50 or 60 Hz |

| Power | 800 VA, exclusive of vacuum pumps, which are powered separately |

Environment

| Temperature | 10 to 30 °C operating, -10 to 55 °C storage or shipping |

| Humidity | Up to 90% relative (non-condensing) for instrument. |

Capacity

| Analysis System | 6 sample ports, each with a constantly monitored saturation pressure port |

| Degas System | 12 degas ports, each with independently controlled heating mantle |

Analysis System

| Manifold Temperature Transducer | Type: Platinum resistance device (RTD) Accuracy: ±0.10 °C by keyboard entry Stability: ±0.10 °C per month |

| Manifold Pressure Transducer | Range: Vacuum to 950 mmHg operating: 1000 mmHg maximum 10 mmHg added for krypton option 1 mmHg for micropore optionResolution: 1000 mmHg Transducer: 0.01 mmHg 10 mmHg Transducer: 0.0001 mm 1 mmHg Transducer: 0.00001 mmAccuracy: 1000 mmHg Transducer: within 0.1% FS 10 mmHg Transducer1 : within 0.15% of reading 1 mmHg Transducer2 : within within 0.12% of reading |

| Sample Port Transducer and Po Port Transducers | Range: 0 to 950 mmHg Resolution: 0.01 mmHg Accuracy: ±0.1% Full Scale |

| Vacuum Gauge | Type: Thermocouple Range: 0.001 to 1 mmHg |

Physical

| Height | 159 cm (62.5 in.) |

| Width | 103 cm (40.5 in.) |

| Depth | 51 cm (20.2 in.) |

| Weight | 160 kg (350 lb) |

Vacuum System

| Nitrogen System Pumps | 2 oil-based pumps: 1 analysis, 1 degas 4 pumps (optional): 2 oil-free (1 analysis, 1 degas), 2 high vacuum (1 analysis, 1 degas) |

| Krypton & Micropore Pumps | Oil-based mechanical pump: 5 x 10-3 mmHg ultimate vacuum Oil-free and high vacuum pump: 3.8 x 10-9 mmHg ultimate vacuum3 |

Degas System

| Capacity | 12 degas ports |

| Vacuum Control | Selectable target pressure controls switchover from restricted to unrestricted evacuation |

| Evacuation | Selectable evacuation rate from 1.0 to 50.0 mmHg/s |

| Manifold Pressure Transducer | Range: 0 to 950 mmHg Resolution: 0.01 mmHg Accuracy: ±0.1% Full Scale |

| Vacuum Transducer | Type: Thermocouple Range: 0.001 to 1 mmHg |

| Titled Backfill Gas | User-selectable at dedicated port, typically nitrogen or helium |

| Temperature Control | Temperature Range: Ambient to 450 °C (Programmable) Temperature Control: 1 ramp during evacuation phase, 5 additional selectable ramps during heating phase Selection: Digitally set, 1 °C increments from computer Accuracy: Deviation less than ±10 °C of set point at the sensing thermocouple embedded in the heating mantle |

Computer Requirements

Windows® 7 Professional or higher operating system recommended (64 bit)4 USB port5 Ethernet port (10 base T or 100 base T)

ASAP 2460 Specifications

ASAP 2460 Specifications

Electrical

| Voltage | 100/115/230 VAC (± 10%) |

| Frequency | 50 or 60 Hz |

| Power | 800 VA, exclusive of vacuum pumps, which are powered separately |

Environment

| Temperature | 10 to 30 °C operating, -10 to 55 °C storage or shipping |

| Humidity | Up to 90% relative (non-condensing) for instrument. |

Capacity

| Analysis System | 2, 4, or 6 sample ports (for krypton analysis, one sample port is used for dosing), each with a constantly monitored saturation pressure port |

Analysis System

| Manifold Temperature Transducer | Type: Platinum resistance device (RTD) Accuracy: ±0.10 °C by keyboard entry Stability: ±0.10 °C per month |

| Manifold Pressure Transducer | Range: 0 to 950 mmHg operating: 1000 mmHg maximum 0 to 10 mmHg added for Krypton option Resolution: 1000-mmHg Transducer: 0.001 mmHg 10-mmHg Transducer1: 0.00001 mmHg 1-mmHg Transducer**: 0.000001 mmHg Accuracy: 1000-mmHg Transducer: within 0.15% of reading 10-mmHg Transducer1: within 0.15% of reading 1-mmHg Transducer2: within 0.12% of reading |

| Sample Port Transducer and Po Port Transducers | Range: 0 to 950 mmHg Resolution: 0.001 mmHg Accuracy: ±0.1% Full Scale |

| Vacuum Transducer | Type: Thermocouple Range: 0.001 to 1 mmHg |

Physical

| Height | 94 cm (37 in.) |

| Width | 38 cm (15 in.) |

| Depth | 59 cm (23 in.) |

| Weight | 54 kg (119 lb) |

Vacuum System

| Pumps3 | Nitrogen: Oil-sealed pump Krypton & enhanced micropore option: High-vacuum pump |

Computer Requirements: Windows® 7 Professional or higher operating system (64 bit)5,7 USB port6 Ethernet port (10 base T or 100 base T)

Includes nonlinearity, hysteresis, and non-repeatability.

1The 10-mmHg transducer is active only when performing krypton analyses

2The 1-mmHg transducer is presented only in the enhanced micropore option

3Oil-free and high vacuum pump: 3.8 × 10-9 mmHg ultimate vacuum4

4Ultimate vacuum measured by pump manufacturer according to Pneurop Standard 5608 Due to continuous improvements, specifications are subject to change without notice.

5For 21 CFR Part 11, Windows 10 Professional or Windows 10 Enterprise or higher is required.

6One additional USB port must be available for Instrument.

7Not be installed on a network drive with shared access. Multiple users cannot operate the application at the same time.

Due to continuous improvements, specifications are subject to change without notice

Analysis System

- With six independently operated analysis ports, a new analysis can begin as soon as another is finished.

This provides an important advantage over many multiport instruments that require all samples to be

prepared or analyzed at the same time. - Long-duration Dewars and Micromeritics Isothermal Jackets1 assure a constant thermal profile along

the length of both the sample and saturation pressure (Po) tubes throughout extended analyses.

The Po value may be entered, or measured either continuously or at selected intervals. - The high-capacity Dewar also allows unattended analysis of high-resolution adsorption/desorption

isotherms that take much longer to complete because the system must equilibrate at each data point. - BET surface area analyses utilizing six parallel runs can be achieved in as little as 1 hour.

- A low surface area option that uses krypton as an adsorptive to measure total surface areas of 0.5 m2 or less is available. This option utilizes five of the six available ports. It also features a turbomolecular drag pump, which provides the high vacuum required for krypton analyses, and a 10 mmHg pressure transducer, which allows accurate, repeatable pressure resolution.

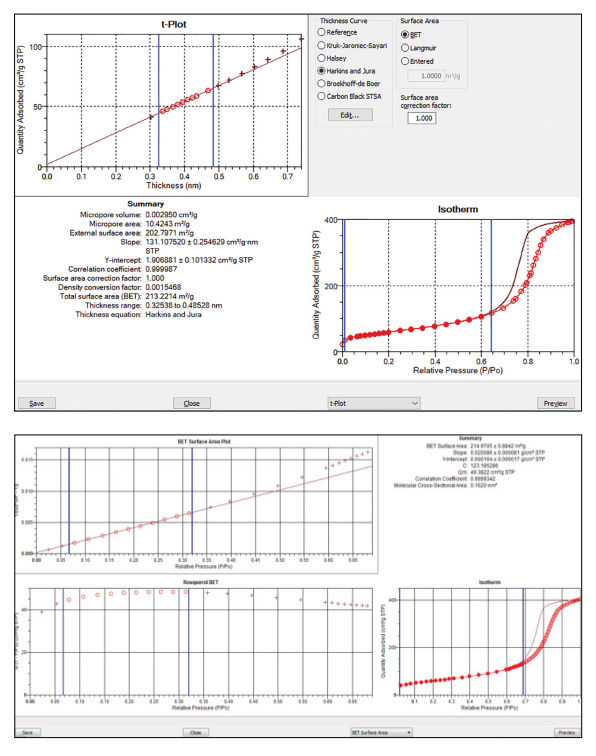

- Intuitive Micromeritics MicroActive software combines user-defined reports with the ability to interactively evaluate isotherm data. User-selectable data ranges through the graphic interface allow direct modeling for BET, t-Plot, Langmuir, DFT interpretation, and new advanced NLDFT methods.

- Up to five different nonreactive adsorptives, plus an additional gas for free space, can be attached to the analyzer simultaneously.

- The servo pressure control regulates dosing and evacuation during analysis to reduce analysis time.

Sample Preparation System

- The ASAP 2425 system includes twelve automatically controlled sample preparation ports that operate

independently. Samples may be added or removed from degas ports without disturbing the treatment of

other samples undergoing preparation. - The sample preparation system is fully automated with controlled heating time profiles. Temperature

and ramp rate can be set and monitored individually and controlled from a few degrees above ambient

to 450 °C. The temperature hold period may extend past the point when evacuation is completed. - A programmable pressure threshold can suspend the temperature ramp if the outgassing pressure exceeds the limit specified, preventing destructive steaming or other undesired reactions with residual gasses and vapors.

Low Surface Area Measurement (Krypton) and Micropore Options

In addition to the standard ASAP 2425, low surface area krypton and micropore models are available.

Low surface area (krypton) model includes the addition of a 10 mmHg transducer and permits accurate

measurement of very low surface area materials (< 1 m2/g).

The micropore model includes the addition of a 1 mmHg transducer which extends the low pressure measurement capabilities and allows enhanced performance for characterizing microporous materials. The transducer also increases pressure resolution in the range necessary for micropore analysis.

Application

Pharmaceuticals

Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bioavailability.

Ceramics

Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

Adsorbents

Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

Activated Carbons

Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in waste-water management.

Carbon Black

The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production.

Catalyst

The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

Paints and Coatings

The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness, solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

Projectile Propellant

The burn rate of propellants is a function of surface area. Too high a rate can be dangerous; too low a rate can cause malfunction and inaccuracy.

Medical Implants

Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

Electronics

By selecting high surface area material with carefully designed pore networks, manufacturers of super-capacitors can minimize the use of costly raw materials while providing more exposed surface area for storage of charge.

Cosmetics

Surface area is often used by cosmetic manufacturers as a predictor of particle size when agglomeration tendencies of the fine powders make analysis with a particle-sizing instrument difficult.

Aerospace

Surface area and porosity of heat shields and insulating materials affect weight and function.

Geoscience

Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

Nanotubes

Nanotube surface area and microporosity are used to predict the capacity of a material to store hydrogen.

Fuel Cells

Fuel cell electrodes require high surface area with controlled porosity to produce optimum power density.

Superior Data Presentation Capability

Innovative MicroActive Software

Micromeritics’ innovative MicroActive software allows users to interactively evaluate isotherm data. Users can

easily include or exclude data, fitting the desired range of experimentally acquired data points using interactive,

movable calculation bars. Isotherms can be viewed on either a linear or logarithmic scale.

Data Reduction Benefits

- Interaction with adsorption data is direct. By simply moving the calculation bars, the user is immediately updated with new textual properties.

- Interactive data manipulation minimizes the use of dialog boxes and tunneling of dialogs to specify

calculation parameters. - Ability to overlay files (up to 25) including mercury intrusion data with a file add-and-subtract feature.

- User-selectable data ranges through the graphic interface allow direct modeling for BET, t-Plot, Langmuir,

DFT interpretation, and much more. - Report Options editor allows the user to define reports with on-screen previews. Information from each

report can be included in a concise summary, as well as in a tabular and graphical information pane.

ASAP 2425 Interactive Reports include (when appropriate to the analysis performed):

- Isotherm

- BET Surface Area

- Langmuir Surface Area

- t-Plot

- Alpha-S Method

- BJH Adsorption and Desorption

- Dollimore-Heal Adsorption and Desorption

- Horvath-Kawazoe

- Saito-Foley

- Cheng-Yang

- MP-Method

- DFT Pore Size and Surface Energy

- Dubinin-Radushkevich

- Dubinin-Astakhov

- NLDFT Advanced Reports

- User-Defined Reports

ASAP 2460 & 2425 Resources

Standard Methods

- ASTM D3908 Standard Test Method for Hydrogen Chemisorption on Supported Platinum Catalysts by Volumetric Vacuum Method

- ASTM D4824 Standard Test Method for Determination of Catalyst Acidity by Ammonia Chemisorption

- WK61828 Carbon Monoxide on Supported Platinum on Alumina Catalysts using Manometric Method

- WK71859 Carbon Monoxide Chemisorption on Supported Platinum on Alumina Catalysts using Static Vacuum Method

- ASTM D4780 Standard Test Method for Determination of Low Surface Area of Catalysts and Catalyst Carriers by Multipoint Krypton Adsorption

- ASTM E2864 Standard Test Method for Measurement of Airborne Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers using Krypton Gas Adsorption

- ISO 15901-3 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 3: ANALYSIS OF MICROPORES BY GAS ADSORPTION

- ASTM D5604 Standard Test Methods for Precipitated Silica—Surface Area by Single Point B.E.T. Nitrogen Adsorption

- ISO 4652 RUBBER COMPOUNDING INGREDIENTS — CARBON BLACK — DETERMINATION OF SPECIFIC SURFACE AREA BY NITROGEN ADSORPTION METHODS — SINGLE-POINT PROCEDURES

- ISO 9277 DETERMINATION OF THE SPECIFIC SURFACE AREA OF SOLIDS BY GAS ADSORPTION — BET METHOD

- ASTM B922 Standard Test Method for Metal Powder Specific Surface Area by Physical Adsorption

- ASTM C1069 Standard Test Method for Specific Surface Area of Alumina or Quartz by Nitrogen Adsorption

- ASTM C1274 Standard Test Method for Advanced Ceramic Specific Surface Area by Physical Adsorption

- ASTM D1993 Standard Test Method for Precipitated Silica-Surface Area by Multipoint BET Nitrogen Adsorption

- ASTM D3663 Standard Test Method for Surface Area of Catalysts and Catalyst Carriers

- ASTM D4222 Standard Test Method for Determination of Nitrogen Adsorption and Desorption Isotherms of Catalysts and Catalyst Carriers by Static Volumetric Measurements

- ASTM D4365 Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

- ASTM D4641 Standard Practice for Calculation of Pore Size Distributions of Catalysts and Catalyst Carriers from Nitrogen Desorption Isotherms

- ASTM D6556 Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen Adsorption

- ASTM D8325 Standard Guide for Evaluation of Nuclear Graphite Surface Area and Porosity by Gas Adsorption Measurements

- ISO 12800 NUCLEAR FUEL TECHNOLOGY — GUIDELINES ON THE MEASUREMENT OF THE SPECIFIC SURFACE AREA OF URANIUM OXIDE POWDERS BY THE BET METHOD

- ISO 15901-2 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 2: ANALYSIS OF MESOPORES AND MACROPORES BY GAS ADSORPTION

- ISO 18757 FINE CERAMICS (ADVANCED CERAMICS, ADVANCED TECHNICAL CERAMICS) — DETERMINATION OF SPECIFIC SURFACE AREA OF CERAMIC POWDERS BY GAS ADSORPTION USING THE BET METHOD

- ISO 18852 RUBBER COMPOUNDING INGREDIENTS — DETERMINATION OF MULTIPOINT NITROGEN SURFACE AREA (NSA) AND STATISTICAL THICKNESS SURFACE AREA (STSA)

- USP <846> Specific Surface Area

- ASTM C110 Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone