Micromeritics Sub-Sieve AutoSizer II 5800

Modernized, fully automated version of the Fisher Model 95 Sub-Sieve Sizer (FSSS) for particle size, surface area, and powder bed porosity

- Built-in computer with intuitive touchscreen

- Uses a high-quality mass flow controller and high sensitivity transducers for the highest accuracy in air pressure control and monitoring

- Live data monitoring with results generated in minutes on the touchscreen

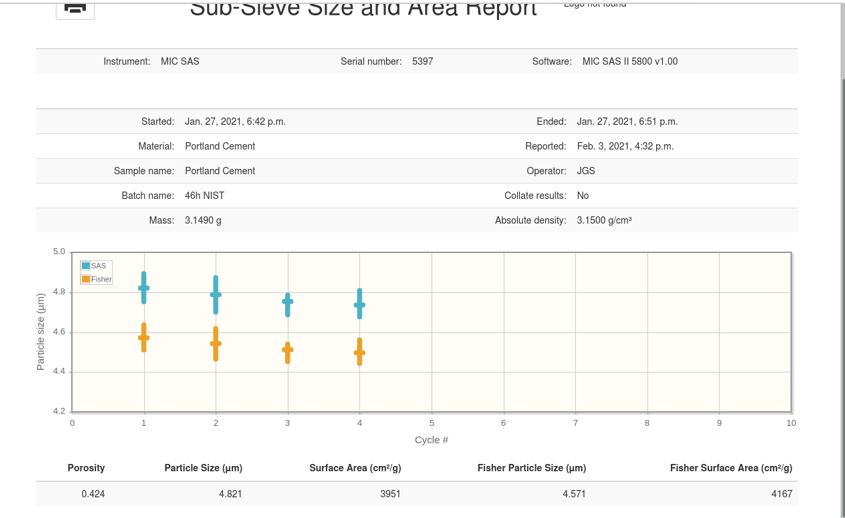

- Fisher mapping tool available to report equivalent Fisher Number results

- Small footprint

The Micromeritics Sub-Sieve AutoSizer (SAS) II determines particle size, surface area, and powder bed porosity by air permeability.

Developed as a direct and modernized successor to the widely used Fisher Model 95 Subsieve Sizer (FSSS), the Micromeritics SAS II utilizes a built-in computer and touchscreen to perform measurements easily and quickly in a laboratory setting or on a production floor. Data can be saved, printed, or exported electronically in spreadsheet or PDF formats.

The Micromeritics Sub-Sieve AutoSizer II generates “Fisher number” results highly consistent with that of its predecessor (the Fisher FSSS), using the built-in Fisher Mapping feature. This is a crucial point, as the air permeability technique and the FSSS have been used as a benchmark for decades in many industries. Many applications use historical data and quality control standards, and a modern source of comparable, repeatable results is necessary.

Features and Benefits:

- Superior Software – Sets a world-wide standard for instrument operation, data acquisition and handling, reporting and systems integration

- Quick and Easy Set-up – Simple step by step set-up, easy to follow; ensuring that no parameters are overlooked

- Real Time Data Display – Data can be viewed as it is acquired simplifying method development

- Fisher Mapping – Optimizes data agreement with customizable Fisher correlation

- ASTM Approval – Fully compliant with ASTM B330-12 and C721-14 standards for particle sizing of alumina, silica, and metal powders and related compounds. B330-15 – Metal Powders; C721-15 – Al2O3, SiO2 – Ceramics & E2980 – 15 – General particle size

- Fully Automated Analysis – Sample compaction and pressure stability are computer controlled for high repeatability

- Report Generation – Automatically creates PDF reports with custom company logos and typestyles

- New Powerful Intuitive Touchscreen – User interface increases productivity and enables easy creation and retrieval of SOPs and collected data

Specifications

Physical

| Height | 50 cm (19.7 in) |

| Width | 44 cm (17 in) |

| Depth | 27 cm (10.6 in) |

| Weight | 16 kg (35 lb) |

Electrical

| Voltage | 100-240 VAC ±10% |

| Frequency | 50 – 60 Hz |

| Electrical Power | 120 W |

Particle Size Range

| Particle Size Range | 0.5 – 75µm |

Porosity Range

| Porosity Range | 20 – 90% |

Compression Accuracy

| Compression Accuracy | <0.05 mm |

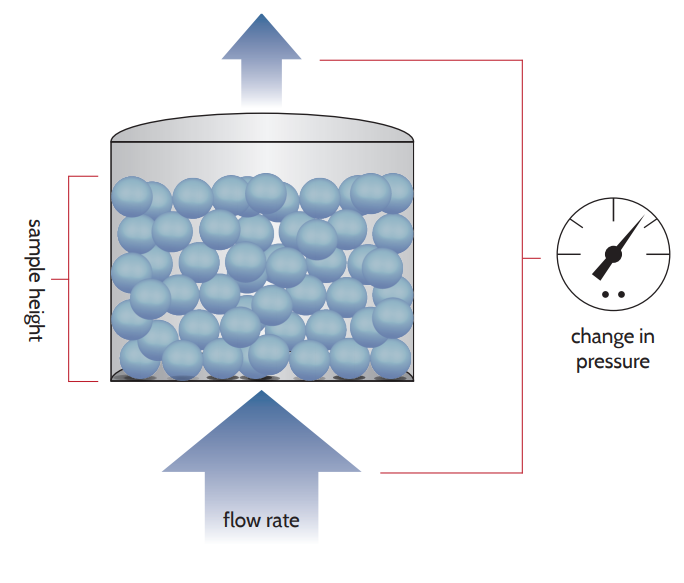

What is Air-Permeability Particle Sizing?

The air-permeability technique is well established for measurement of the Specific Surface Area (SSA) of a sample powder. The SSA measured by this technique has been found to be a useful parameter in various industries such as pharmaceutical, metal coatings, paints, and even geological samples.

The MIC SAS II utilizes dual pressure transducers to measure pressure drop across a packed bed of powder. By varying the sample height and porosity while controlling the flow rate of air through the sample, the SSA and average particle size can be determined using the Kozney-Carmen equation.

Accessories

Quote AccessoriesSoftware

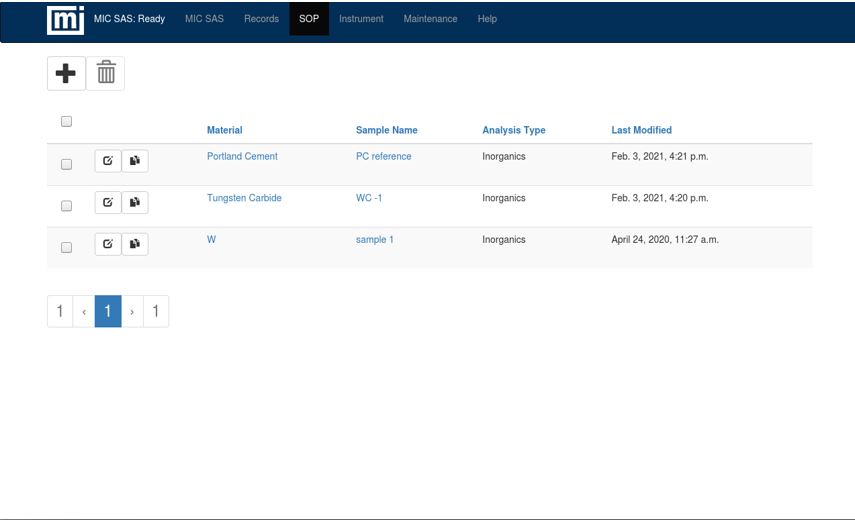

Step 1 – Standard Operating Procedures Create or View available SOPs

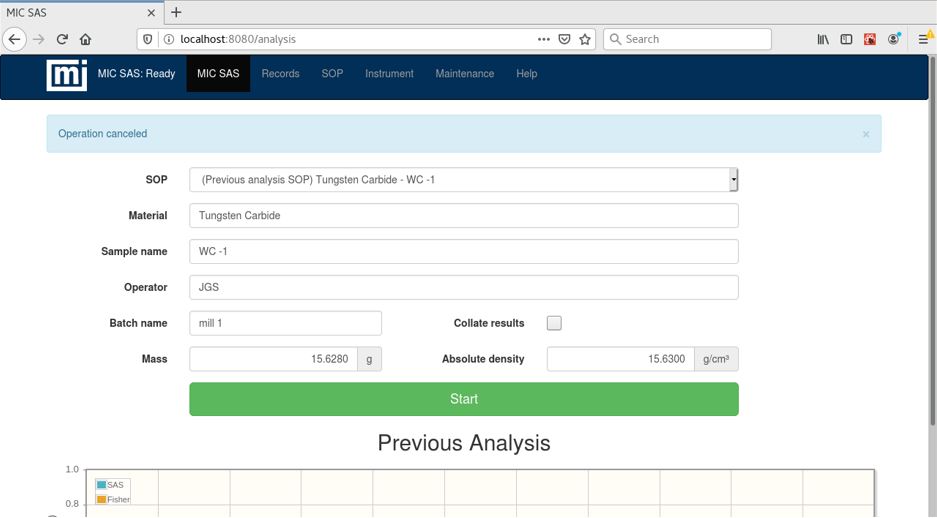

Step 2- Home Screen: MIC SAS Select SOP from dropdown, enter sample info and click start

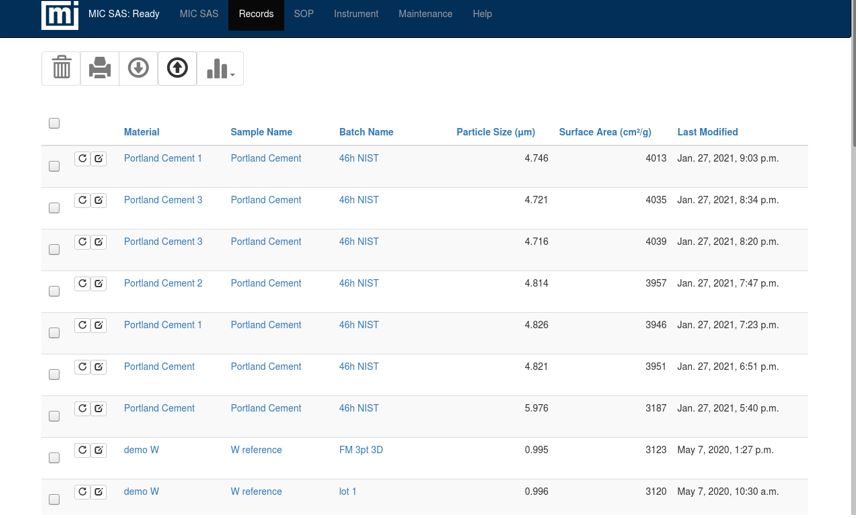

Step 3a – Records: View collected data with Size and SA summary

Step 3b- Report from Records screen View collected data

Extra Info: Instrument View instrument Status and Manual Controls

MICSAS II Resources

Application Notes

Standard Methods

- ISO 10070 METALLIC POWDERS – DETERMINATION OF ENVELOPE-SPECIFIC SURFACE AREA FROM MEASUREMENTS OF THE PERMEABILITY TO AIR OF A POWDER BED UNDER STEADY-STATE FLOW CONDITIONS

- ASTM B330 Standard Test Methods for Estimating Average Particle Size of Metal Powders and Related Compounds Using Air Permeability

- ASTM C721 Standard Test Methods for Estimating Average Particle Size of Alumina and Silica Powders by Air Permeability

- ASTM E2980 Standard Test Methods for Estimating Average Particle Size of Powders Using Air Permeability