Flex & 3Flex

Surface Area, Porosity, Chemisorption, and Temperature Programmed Methods

- High precision gas adsorption for surface area and porosity measurements

- Vapor sorption for application specific studies

- Chemisorption and dynamic adsorption studies for characterizing active surfaces

- Analysis sequencing for automatically measuring physisorption, chemisorption, and dynamic sorption on a single sample

The Flex family of high-performance adsorption analyzers for measuring surface area, pore size, and pore volume of powders and particulate materials. Standard methods or user customized protocols can be used to characterize adsorbents, catalysts, zeolites, MOFs, APIs, excipients, and a wide variety of porous and non-porous materials. The 3Flex is ideally suited for gas or vapor adsorption analysis of microporous (< 2nm) and mesoporous (2 to 50nm) materials and delivers superior accuracy, resolution and data reduction.

A chemisorption option extends the application range of both Flex to both physical and chemical adsorption for characterizing the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

The TCD option adds dynamic chemisorption and temperature programmed methods, and further increases the analytical methods available in a single adsorption analyzer. The TCD option adds temperature programmed reduction (TPR), oxidation (TPO), desorption (TPD), and surface reactions (TPSR) for measuring textural properties and chemisorption. The TCD analysis range can be extended with an option for pulse chemisorption with the addition of an automated injection loop. The TCD also includes a pulse chemisorption TCD.

Features and Benefits

High Resolution, HighThroughput Physisorption and Chemisorption Instrument

Recognized as the most advanced instrument in the field for material surface characterization . The Flex and 3Flex have become a crucial tool for providing high resolution adsorption and desorption isotherms to advance and validate fundamental understanding into development of methodologies and process improvements.

Extend and Increase Your Knowledge

3Flex permits you to optimize experimental parameters to gain greater understanding of your material. The 3Flex has the capability to analyze a sample with 3 separate probe gases simultaneously, one on each analysis port, within a single run.

Extend Your Range of Study

Go beyond micropore and extend your range of resolution to the ultramicroporous level. The advanced transducer technology and vacuum management of the 3Flex permits you to collect adsorption isothems and the pore size distributions for materials with pores as small as 0.3nm.

Optimize Your Material

With the Flex or 3Flex you gain valuable information to validate your theories and rationalize the design and synthesis of MOFs, zeolites, activated carbons and other products. Utilize the high throughput results from the 3-port mesopore & micropore design of the 3Flex to rapidly characterize & understand surface area, porosity, and adsorption capacity of your high performance materials.

Specifications

| 3Flex Physisorption Only | 3Flex Chemisorption | |

| Analysis Range | 1.3 x 10-9 to 1.0 P/P0 | 1 x 10-6 to 900 torr |

| Available Micropore Ports | up to 3 | up to 3, one port dual purpose chemisorption and physisorption |

| Dosing and Evacuation Control | Proprietary Servo | Proprietary Servo |

| Roughing Pump | 4 stage diaphragm | 4 stage diaphragm |

| Krypton Analysis | Standard 1 port, optional up to 3 ports | Standard 1 port, optional up to 3 ports |

| Analysis Gas Per Sample | Ability to use up to 3 gases concurrently, one probe gas on each port |

| Minimum Measurable Surface Area | Standard 0.01 m2 /g 0.01 m2 /g Krypton 0.0005 m2 /g 0.0005 m2 /g |

| 3Flex Physisorption Only | 3Flex Chemisorption | |

| Temperature Control | 45 °C, ±0.05 °C with 3 strategically placed RTDs | 45 °C, ±0.05 °C with 3 strategically placed RTDs |

| Adsorptive Gas Inlets | 6 | 12 standard; optional up to 16 |

| Vapor Sorption Option | Standard ports 1 and 2, optional port 3 with heated vapor source | Standard ports 1 and 2, optional port 3 with heated vapor source |

| Furnace | N/A | Ambient to 1100°C

Programmable from 0.1 to 50 °C/min |

| Mass Flow Controller | N/A | Standard, flow up to 200 cm3/min |

| TCD & cold trap for TPx | N/A | Optional |

| Automated Loop for pulse chemisorption | Optional and requires TCD & cold trap | |

| Dedicated Port for Residual Gas Analysis | N/A | Included |

| Software Interface Control (for Calorimeter or Spectrometer) | Included | Included |

| Degas | 3 in situ, 6 additional with SmartVac Prep | 3 in situ, 6 additional with SmartVac Prep |

| A/D data acquisition | 29 bit (effective 25) | 29 bit (effective 25) |

| Pressure Transducer System | up to 12 | up to 12 |

| Transducer Accuracy | 1000 torr 0.12% reading

10 torr 0.12% reading 0.1 torr 0.15% reading |

1000 torr 0.12% reading

10 torr 0.12% reading 0.1 torr 0.15% reading |

Cryogen

| 3Flex Physisorption Only | 3Flex Chemisorption | |

| Cryogen Dewar | 3.2 L, greater than 70 hrs virtually unlimited with refill during analysis | 3.2 L, greater than 70 hrs virtually unlimited with refill during analysis |

| Cryogen Free Space Control | Isothermal Jacket | Isothermal Jacket |

Reports

| Advanced Modeling | GAB, Sips, Toth, dissociative Langmuir, Redlich-Peterson |

| Instrument Operation Dashboard | Dashboard permits real-time monitoring of critical parameters |

Minimized Bench Space Footprint

| 3Flex Physisorption Only | 3Flex Chemisorption | |

| Height | 112cm | 112cm |

| Width | 57.2cm | 57.2cm |

| Depth | 61cm | 61cm |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Advancements in Performance and Technology

- Provides superior mesopore/micropore, physisorption, or chemisorption analyses. Ports can be configured for krypton analysis of low surface area materials

- One or three configurable analysis ports adapt to the specific needs of your workflow

- Standard configuration includes vapor sorption capabilities and an optional heated vapor source is available to extend the analysis range.

- Analysis sequencing of experiments provides the unique capability to collect surface area and porosity using physisorption, active area and crystallite size using chemisorption, and TPx data without removing the sample from the analyzer.

- Ultra-clean manifold design features hard-seal valves and chemically resistant metal seals to provide chemical compatibility, increased evacuation speed and vacuum performance, and lowest outgasing rate in the industry.

- Po port with dedicated pressure transducer allows continuous monitoring of saturation pressure

- Isotherm data collection begins in the 10-6 Torr range (10-9 relative pressure range for N2)

- MicroActive™ Data Reduction software provides powerful yet intuitive data analysis

- Rapidly collect high resolution adsorption isotherms with the advanced dosing methods proprietary hardware and analyzer control of pressure and volume adsorbed specifications

- Small footprint conserves valuable bench space

- Analyze a sample with three separate adsorbent gases simultaneously, one at each port in a single analysis

Configurations

Physisorption Option

Physisorption

Advancements in Performance:

- 3Flex features three configurable analysis ports adapt to the specific needs of your workflow

- Flex is a high resolution, single-port physisorption analyser

- Research-grade instrument provides superior mesopore/micropore, physisorption, or chemisorption analyses. Ports can be configured for krypton analysis of low surface area materials

- Vapor sorption capability

- Ultra-clean manifold design features hard-seal valves and metal seals to provide high chemical resistivity, ease of evacuation, and lowest outgasing rate in the industry

- Isotherm data collection begins in the 10-6 Torr range (10-9 relative pressure range for N2)

- MicroActive™ Data Reduction software provides powerful, yet intuitive, data analysis

- Advanced dosing method permits user to combine pressure and volume increments

- Small footprint conserves valuable lab bench space

- Analyze a sample with 3 separate adsorbent gases simultaneously, one at each port in a single analysis

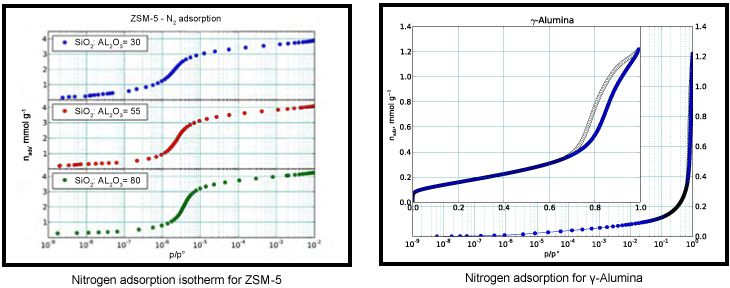

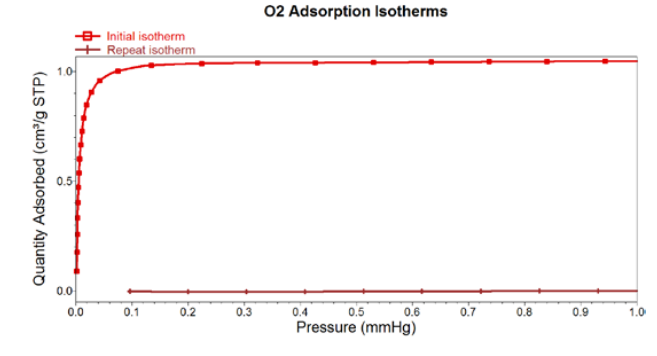

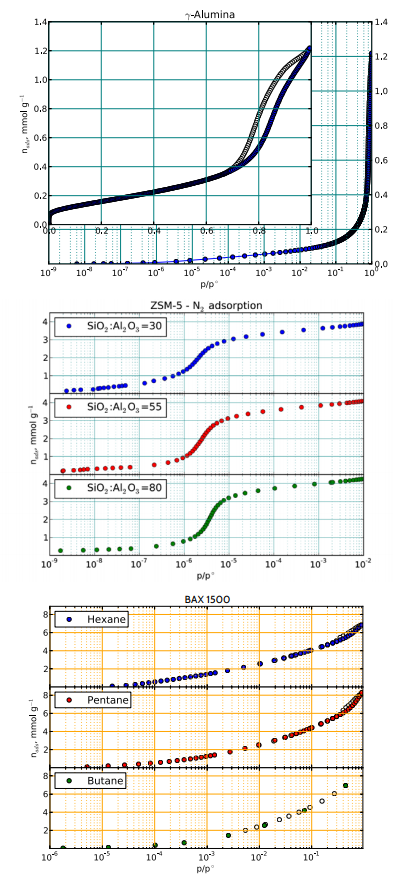

High-Resolution Isotherms

The new manifold design and embedded control provides an ultra-stable environment for pressure and temperature measurements. In addition to hardware advancements, several software advancements including a new advanced dosing method that allows you to mix both pressure and volume increments.

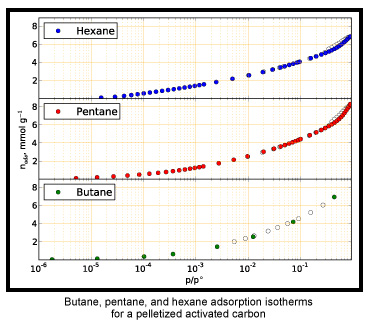

Vapor Isotherms

An extensive library of fluid properties of fixed gases and commonly used vapors are included to maximize the analysis capabilities. Isotherm data are easily collected using hydrocarbons as the adsorptive.

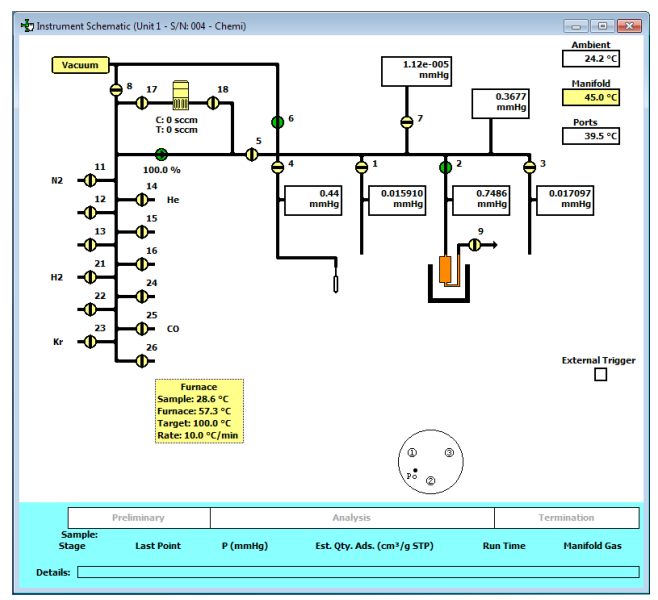

The 3Flex Chemisorption Option

Catalyst Characterization: The Chemisorption Option

With the chemisorption option, the Flex & 3Flex are configured to perform chemical adsorption analyses that enable the researcher to obtain valuable information about the physical or chemical properties of catalysts, catalyst supports, and a variety of other materials.

With the chemisorption option, the Flex & 3Flex are configured to perform chemical adsorption analyses that enable the researcher to obtain valuable information about the physical or chemical properties of catalysts, catalyst supports, and a variety of other materials.

This versatile instrument permits you to change from chemisorption to physisorption analysis in minutes.

- VCR seals provide higher levels of system cleanliness, low outgas rates, and base pressures. The result is accurate low-pressure chemisorption isotherms and the ability to measure oxygen-sensitive materials

- Standard high-precision mass flow controller provides extremely accurate, programmable gas control

- High-temperature furnace (up to 1100°C) provides quick and accurate ramp rates to desired temperature

with precise temperature control and repeatability (±1°C) - Up to a total of sixteen* gas inlets allow multiple probe gases to be investigated maximizing efficiency

and range of applications - Superior temperature control maintains accuracy and repeatability in monotonic isotherms

- Design permits transition from chemisorption to micropore physisorption within minutes

- New high-temperature, precision quartz cell improves accuracy and sensitivity for challenging analyses

- Heated vapor can also be used as the adsorptive for chemical adsorption analyses

- Kalrez, Vition, or Buna O-rings provide maximum flexibility for chemical compatibility

Only available optional level 2 TCD

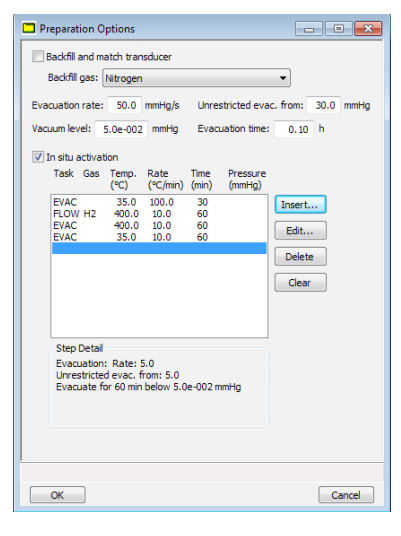

Superior Hardware Versatility Up to sixteen-inlet* gas manifold is standard with the chemisorption capability. Flow control during sample

activation utilizes a mass flow controller (MFC) for precise and repeatable sample preparation. The MFC is included in the standard chemisorption hardware.

In situ Sample Preparation and Activation In situ preparation and activation provide a fully automated method that does not require user intervention and fully integrates activation and analysis into one simple-to-use application. Flexible pre-treatment options allow for

reduction, oxidation, evacuation, and purging

Sample Analysis Options

Sample Analysis Options

- Gas selection

- Free space measured at both ambient and analysis temperature

- Dosing options added to the pressure table give you the ability to change the pressure increment, volume dose increment, and equilibrium interval time between data points

- Dosing from gas inlets or vapor source

- Automatically repeat isotherm to analyze reversible sorption

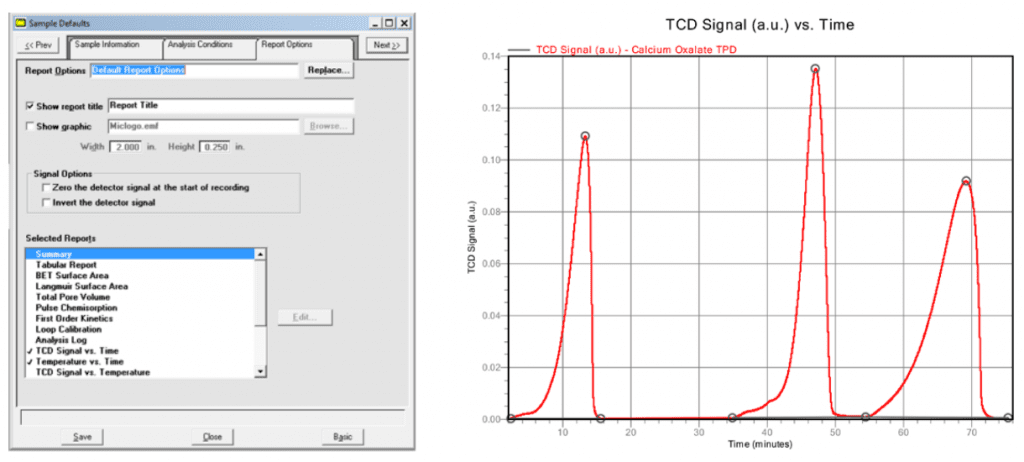

Chemi-TCD Option

Chemi-TCD Option

Perform High Resolution TPR, TPO, and TPD Experiments

The industry’s most highly recognized and preferred instrument for physisorption and chemisorption, has been made even more powerful.

With the addition of the integral thermal conductivity detector, dynamic chemisorption analyses are available to the user providing the ability to perform temperature programmed reduction (TPR), oxidation (TPO), desorption (TPD), and reactions (TPRx).

The TCD option provides the capability to investigate temperature dependence of specific adsorption or desorption process profiles for catalyst and adsorbents, as well as pulse chemisorption in one very capable instrument.

Chemi-TCD Available Configurations:

| Level 1 | Includes injection port, cold trap, and new analysis protocols in MicroActive to support dynamic chemisorption analyses. |

| Level 2 | Pulse chemisorption adds increased precision, repeatability, and reproducibility by the addition of an injector loop valve with two loop options in addition to four gas inlets, a restrictor for flow control and an industry exclusive; local temp |

Included Features of the TCD Option:

- Time, temperature, and TCD signal are recorded via the newly enhanced MicroActive interactive software. In addition to data collection a full suite of signal processing tools are available to transform raw data to sample property information. These tools include: peak integration, peak deconvolution (curve fitting), and calculation of active surface area, crystallite size, and dispersion.

- Industry exclusive, localized loop valve temperature measurement and control improves precision, signal detectability and repeatability of the precision, detectability, and repeatability in the TCD signal.

- Full versatility; change from chemisorption experiments to physisorption analysis in minutes

Accessories

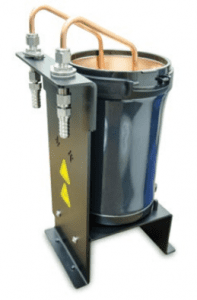

Quote AccessoriesChiller Dewar

Chiller Dewar

Chiller Dewar

Liquid Recirculation System

Micromeritics’ Chiller Dewar is a closed loop recirculating system that utilizes a high surface area copper coil to provide excellent heat transfer between the dewar and the recirculating liquids. Temperature control is provided through an external recirculating bath or chiller bath which are supplied as accessory items

| Temperature Range | -50 °C to 200 °C |

| Temperature Stability | ±0.01 °C |

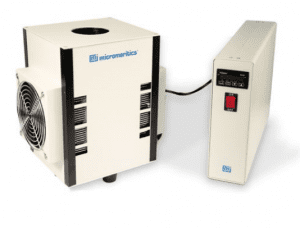

ISO Controller

ISO Controller

ISO Controller

Sub-Ambient, Thermoelectric Cooled Dewar

Micromeritics’ ISO Controller utilizes thermoelectric cooling based on the Peltier principle. The unit is designed to maintain a constant temperature between 0 °C and 80 °C when using CO2, N2 and other gases for adsorption analysis. The device rapidly cools and efficiently maintains temperature with minimal electrical current required.

The dewar section is placed on the instrument dewar elevator and then raised into position for analysis.

| Temperature Range |

0°C to 80°C (lab temp <27 °C) |

| Cooling Capacity | Approx. 80W at 0 °C, 120W at 25 °C |

| Minimum Controllable Resolution | 0.1 °C |

| Temperature Stability | ±0.01 °C |

Cryostat I

Cryostat I

Cryostat I

Single-Stage Cryogenic Refrigerator Based on the Gifford-McMahon Principle

The Micromeritics Cryostat I is a closed-cycle cryocooler based on the Gifford-McMahon (GM) refrigeration principle. It uses helium gas from a helium compressor to generate cryogenic temperatures.

The Cryostat I eliminates the need for liquid nitrogen and can obtain temperatures below the 77 K of liquid nitrogen.

| Temperature Range | 25 to 350 K |

| Temperature Stability | ±0.005 K |

| Nitrogen Reservoir | closed-cycle helium |

| Cool Down Time to Stated Minimum from Ambient | 60 minutes |

Physi - Consumables & Supplies

Physi – Consumables & Supplies

3Flex Chemi - Consumables & Supplies

Chemi – Consumables & Supplies

TCD - Consumables & Supplies

TCD – Consumables & Supplies

Application

Metal Organic Frameworks and Porous...

Metal Organic Frameworks and Porous Organic Polymers

Empowering the Study of Energy Storage and Gas Separations by MOFs and POPs

Investigate the influence of Hydrogen adsorption enthalpy.

Flex & 3Flex has the ability to expediently switch from Physisorption to Chemisorption permitting investigation for enthalpy tied to ligand influence.

Determine the influencing relationship of surface area, pore volume and substrate/analyte interactions for uptake, capacity, and release evaluations.

The 3Flex has the capability to analyze a sample with 3 separate probe gases simultaneously, one on each analysis port, within a single run.

Evaluate optimal small pore size as a strategy to enhance hydrogen–framework interactions.

Superior gas management and temperature control permits accurate and precise micropore and

ultra-micropore (<0.7 nm) measurements.

Advanced Pore Size Analysis with NLDFT Models

MicroActive™ Data Software permits you to graphically capture the desired range of isotherm data using an intutive users interactive reduces the time and effort required to transform data to textural information including surface area and pore size. MicroActive user interface enables you to copy and paste data to your prefered software for further analysis or custom plotting, and the powerful reporting software includes exporting the data to a spreadsheet, saving to PDF, or printing reports.

Advancing understanding for strategy...

Advancing the understanding for strategy and synthesis in zeolite design

Quantitatively determine the number of surface active sites for catalytic potential.

Provide data related to monolayer uptake, metal area, dispersion and crystalite size of the catalysts. The advanced flexibility of the Flex family lets you quickly change from Physisorption analysis to Chemisorption analysis in minutes to permit full characterization in one instrument.

Determine if zeolite processing has resulted in loss of structure or degradation.

The advanced architecture of the Flex & 3Flex provides industry leading micropore resolution and provides complimentary information along with X-Ray diffraction to resolve minor structural defects due to processing.

The advanced design of the 3Flex provides industry leading resolution and accuracy.

Obtain valuable insight for pore architecture to gain greater understanding of transport, diffusion rates and selectivity.

Gain valuable data for improving activated carbon...

Gain valuable data for improving activated carbon adsorbents and catalyst performance

Determine adsorption dynamics in regard to resident time for performance in fixed bed and flow through systems.

Acquire valuable data for greater understanding of the influence of surface area and pore volume and pore size distribution on performance.

Gain valuable insight of structural and chemical heterogeneity influence on adsorption dynamics.

Superior gas management, hard seal valves and metal seals along with precise temperature control

permit accurate and precise micropore measurements.

Evaluate temperature and chemical deactivation processes in regard to porosity and surface activity.

Accurate temperature and gas control ensure repeatable analytical data sample to sample, batch to batch.

High-Resolution and Vapor Isotherms

High-Resolution and Vapor Isotherms

High-Resolution and Vapor Isotherms

The new manifold design and embedded control provides an ultra-stable environment for pressure and temperature measurements. In addition to hardware advancements, software advancements including a new advanced dosing method that allows you to mix both pressure and volume increments.

The Flex & 3Flex includes an extensive library of fluid properties of fixed gases and commonly used vapors. Isotherm data are easily collected using hydrocarbons as the adsorptive.

Software

Data Reduction and Control Software

MicroActive for 3Flex – Data Reduction and Control Software

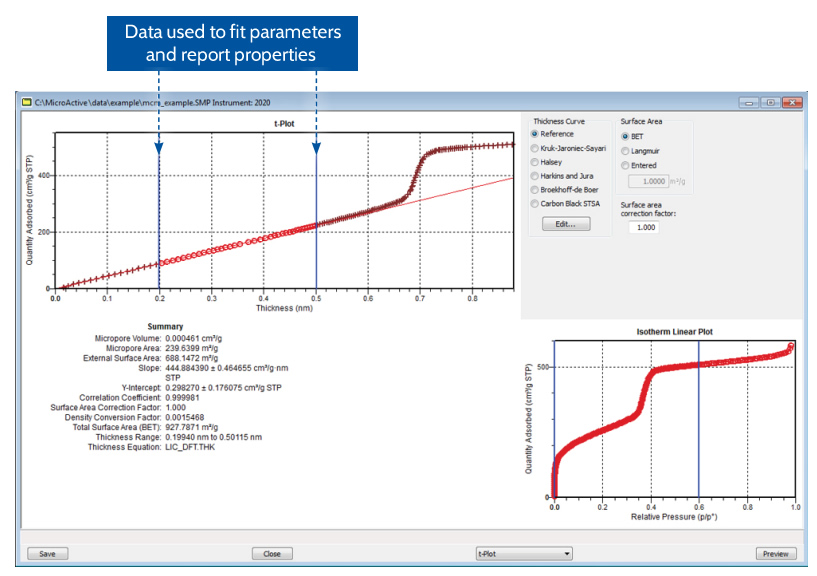

- Interaction with adsorption/desoption data is direct. By simply moving the calculation bars, the user is immediately updated with new textural properties

- Click-and-drag bars slide to select the calculation range, minimizing the use of dialog boxes and tunneling of dialogs to specify calculation parameters

- User-selectable data ranges through the graphic interface allow direct modeling for BET, BJH, t-Plot, Langmuir, DFT interpretation, and much more. The MicroActive isotherm analysis suite provides an extensive selection of NLDFT models for calculating pore size distributions

- Report Options editor allows you to define reports with on-screen previews

- Includes Python programming interface for user defined reports

- Overlay up to 25 files, mercury intrusion results may be overlaid with pore size analysis from the 3Flex

t-Plot analysis of N2 at 77K on MCM-41 silica. The t-Plot calculation shows this is not a microporous material despite the large gas capacity.

3Flex Interactive Reports Include:

- Isotherm

- BET Surface Area

- Langmuir Surface Area

- t-Plot

- Alpha-S Method

- BJH Adsorption and Desorption

- Dollimore-Heal Adsorption and Desorption

- Horvath-Kawazoe

- MP-Method

- DFT Pore Size and Surface Energy

- Dubinin-Radushkevich

- Dubinin-Astakhov

- User-Defined Reports (5)

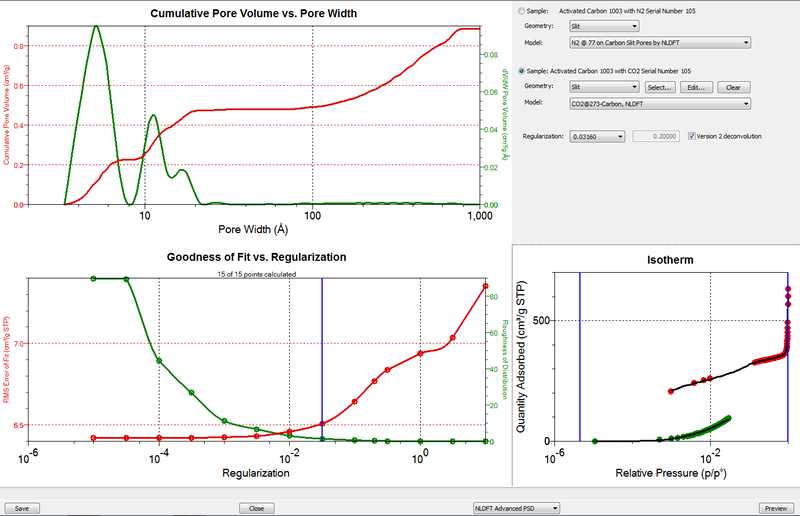

NLDFT Dual Isotherm Deconvolution and Pore Size Distribution

NLDFT Dual Isotherm Deconvolution and Pore Size Distribution

The NLDFT Advanced PSD, Dual DFT modeling allows the user to combine the information gathered from nitrogen/argon and carbon dioxide isotherms to deliver a full pore size distribution on materials (such as carbon slit pores) where pores of molecular sizes are present. The range of pore size analysis in this method is extended to smaller pore sizes compared to the standard nitrogen analysis. This is due to the fact that CO2 can access ultra micropores that are not accessible to N2 at cryogenic temperatures because of diffusion limitations.

This advanced NLDFT method allows you to determine the pore size distribution of your sample using

two isotherms. In this example, CO2 adsorption (green) at 77 K and N2 (red) are used to calculate a single pore-size distribution. You do not have to cut and paste distributions from CO2 and nitrogen—a single distribution is determined using both isotherms.

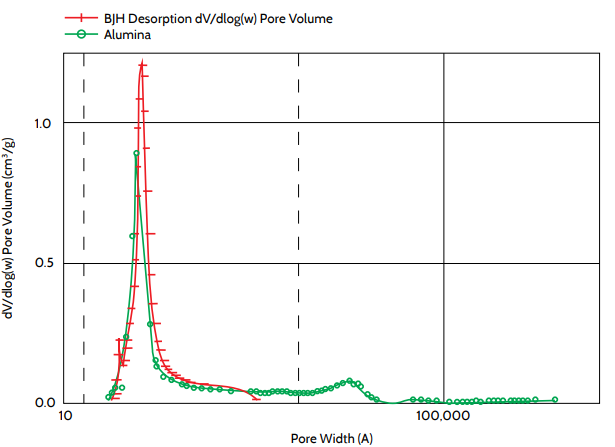

Mercury Porosimetry/Gas Adsorption Overlay

Mercury Porosimetry/Gas Adsorption Overlay

MicroActive for the 3Flex includes a powerful utility that permits you to overlay pore size distributions from mercury porosimetry with those from gas adsorption. This new import function allows you to rapidly view micropore, mesopore, and macropore distributions in a single application.

Overlay of BJH desorption and mercury intrusion log differential pore size distributions for alumina pellets

Resources

Application Notes

- Water Vapor Sorption in Metal-Organic Frameworks Characterized by Micromeritics 3Flex Gas Sorption Analyzer

- Characterization of Carbons Using a Micromeritics 3Flex

- Crystallizing Atomic Xenon in a Flexible MOF to Probe and Understand Its Temperature-Dependent Breathing Behavior and Unusual Gas Adsorption Phenomenon, Journal of the American Chemical Society 142 (2020) 20088-20097. H. Wang, M. Warren, J. Jagiello, S. Jensen, S.K. Ghose, K. Tan, L. Yu, T.J. Emge, T. Thonhauser, J. Li

- Toward understanding reactive adsorption of ammonia on Cu-MOF/graphite oxide nanocomposites, Langmuir : the ACS journal of surfaces and colloids 27 (2011) 13043-13051. C. Petit, L. Huang, J. Jagiello, J. Kenvin, K.E. Gubbins, T.J. Bandosz

- Enhancing the gas adsorption capacities of UiO-66 by nanographite addition, Microporous and Mesoporous Materials 309 (2020) 110571. A. Policicchio, M. Florent, A. Celzard, V. Fierro, J. Jagiello, T.J. Bandosz

- Exploiting the adsorption of simple gases O2 and H2 with minimal quadrupole moments for the dual gas characterization of nanoporous carbons using 2D-NLDFT models, Carbon 160 (2020) 164-175. J. Jagiello, J. Kenvin, C.O. Ania, J.B. Parra, A. Celzard, V. Fierro

- Evaluation of the textural properties of ultramicroporous carbons using experimental and theoretical methods, Carbon 157 (2020) 495-505. D. Grau-Marin, J. Silvestre-Albero, E.O. Jardim, J. Jagiello, W.R. Betz, L.E. Peña

- Consistency of carbon nanopore characteristics derived from adsorption of simple gases and 2D-NLDFT models. Advantages of using adsorption isotherms of oxygen (O2) at 77 K, Journal of Colloid and Interface Science 542 (2019) 151-158. J. Jagiello, J. Kenvin

- Exploring the effect of ultramicropore distribution on gravimetric capacitance of nanoporous carbons, Electrochimica Acta 275 (2018) 236-247. M. Barczak, Y. Elsayed, J. Jagiello, T.J. Bandosz

- Adsorption of Bisphenol A on KOH-activated tyre pyrolysis char, Journal of Environmental Chemical Engineering 6 (2018) 823-833. R. Acosta, D. Nabarlatz, A. Sánchez-Sánchez, J. Jagiello, P. Gadonneix, A. Celzard, V. Fierro

- Quantifying the Complex Pore Architecture of Hierarchical Faujasite Zeolites and the Impact on Diffusion, Advanced Functional Materials 26 (2016) 5621-5630. J. Kenvin, S. Mitchell, M. Sterling, R. Warringham, T.C. Keller, P. Crivelli, J. Jagiello, J. Pérez-Ramírez

- Structural analysis of IPC zeolites and related materials using positron annihilation spectroscopy and high-resolution argon adsorption, Physical Chemistry Chemical Physics 18 (2016) 15269-15277. J. Jagiello, M. Sterling, P. Eliasova, M. Opanasenko, A. Zukal, R.E. Morris, M. Navaro, A. Mayoral, P. Crivelli, R. Warringham, S. Mitchell, J. Perez-Ramirez, J. Cejka

- Direct structural evidence of commensurate-to-incommensurate transition of hydrocarbon adsorption in a microporous metal organic framework, Chemical Science 7 (2016) 759-765. D. Banerjee, H. Wang, Q. Gong, A.M. Plonka, J. Jagiello, H. Wu, W.R. Woerner, T.J. Emge, D.H. Olson, J.B. Parise, J. Li

- Dual gas analysis of microporous carbons using 2D-NLDFT heterogeneous surface model and combined adsorption data of N2 and CO2, Carbon 91 (2015) 330-337. J. Jagiello, C. Ania, J.B. Parra, C. Cook

- Enhanced reactive adsorption of H 2 S on Cu–BTC/S-and N-doped GO composites, Journal of Materials Chemistry A 3 (2015) 8194-8204. A.M. Ebrahim, J. Jagiello, T.J. Bandosz

- The first example of commensurate adsorption of atomic gas in a MOF and effective separation of xenon from other noble gases, Chemical Science 5 (2014) 620-624. H. Wang, K. Yao, Z. Zhang, J. Jagiello, Q. Gong, Y. Han, J. Li

Standard Methods

- ASTM D3908 Standard Test Method for Hydrogen Chemisorption on Supported Platinum Catalysts by Volumetric Vacuum Method

- ASTM D4824 Standard Test Method for Determination of Catalyst Acidity by Ammonia Chemisorption

- WK61828 Carbon Monoxide on Supported Platinum on Alumina Catalysts using Manometric Method

- WK71859 Carbon Monoxide Chemisorption on Supported Platinum on Alumina Catalysts using Static Vacuum Method

- ASTM D4780 Standard Test Method for Determination of Low Surface Area of Catalysts and Catalyst Carriers by Multipoint Krypton Adsorption

- ASTM E2864 Standard Test Method for Measurement of Airborne Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers using Krypton Gas Adsorption

- ISO 15901-3 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 3: ANALYSIS OF MICROPORES BY GAS ADSORPTION

- ASTM D5604 Standard Test Methods for Precipitated Silica—Surface Area by Single Point B.E.T. Nitrogen Adsorption

- ISO 4652 RUBBER COMPOUNDING INGREDIENTS — CARBON BLACK — DETERMINATION OF SPECIFIC SURFACE AREA BY NITROGEN ADSORPTION METHODS — SINGLE-POINT PROCEDURES

- ISO 9277 DETERMINATION OF THE SPECIFIC SURFACE AREA OF SOLIDS BY GAS ADSORPTION — BET METHOD

- ASTM B922 Standard Test Method for Metal Powder Specific Surface Area by Physical Adsorption

- ASTM C1069 Standard Test Method for Specific Surface Area of Alumina or Quartz by Nitrogen Adsorption

- ASTM C1274 Standard Test Method for Advanced Ceramic Specific Surface Area by Physical Adsorption

- ASTM D1993 Standard Test Method for Precipitated Silica-Surface Area by Multipoint BET Nitrogen Adsorption

- ASTM D3663 Standard Test Method for Surface Area of Catalysts and Catalyst Carriers

- ASTM D4222 Standard Test Method for Determination of Nitrogen Adsorption and Desorption Isotherms of Catalysts and Catalyst Carriers by Static Volumetric Measurements

- ASTM D4365 Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

- ASTM D4641 Standard Practice for Calculation of Pore Size Distributions of Catalysts and Catalyst Carriers from Nitrogen Desorption Isotherms

- ASTM D6556 Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen Adsorption

- ASTM D8325 Standard Guide for Evaluation of Nuclear Graphite Surface Area and Porosity by Gas Adsorption Measurements

- ISO 12800 NUCLEAR FUEL TECHNOLOGY — GUIDELINES ON THE MEASUREMENT OF THE SPECIFIC SURFACE AREA OF URANIUM OXIDE POWDERS BY THE BET METHOD

- ISO 15901-2 PORE SIZE DISTRIBUTION AND POROSITY OF SOLID MATERIALS BY MERCURY POROSIMETRY AND GAS ADSORPTION — PART 2: ANALYSIS OF MESOPORES AND MACROPORES BY GAS ADSORPTION

- ISO 18757 FINE CERAMICS (ADVANCED CERAMICS, ADVANCED TECHNICAL CERAMICS) — DETERMINATION OF SPECIFIC SURFACE AREA OF CERAMIC POWDERS BY GAS ADSORPTION USING THE BET METHOD

- ISO 18852 RUBBER COMPOUNDING INGREDIENTS — DETERMINATION OF MULTIPOINT NITROGEN SURFACE AREA (NSA) AND STATISTICAL THICKNESS SURFACE AREA (STSA)

- USP <846> Specific Surface Area

- ASTM C110 Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone