TriStar II Plus

High Throughput Surface Area and Porosity Analyzer

- Competitive cost

- Rapid and accurate measurement

- Fully automated analysis

- Ideal for high throughput sample analysis

- Long lasting dewar to accommodate longer analysis

- Krypton option for low surface area measurements

- High analysis versatility

- Enhanced data reduction

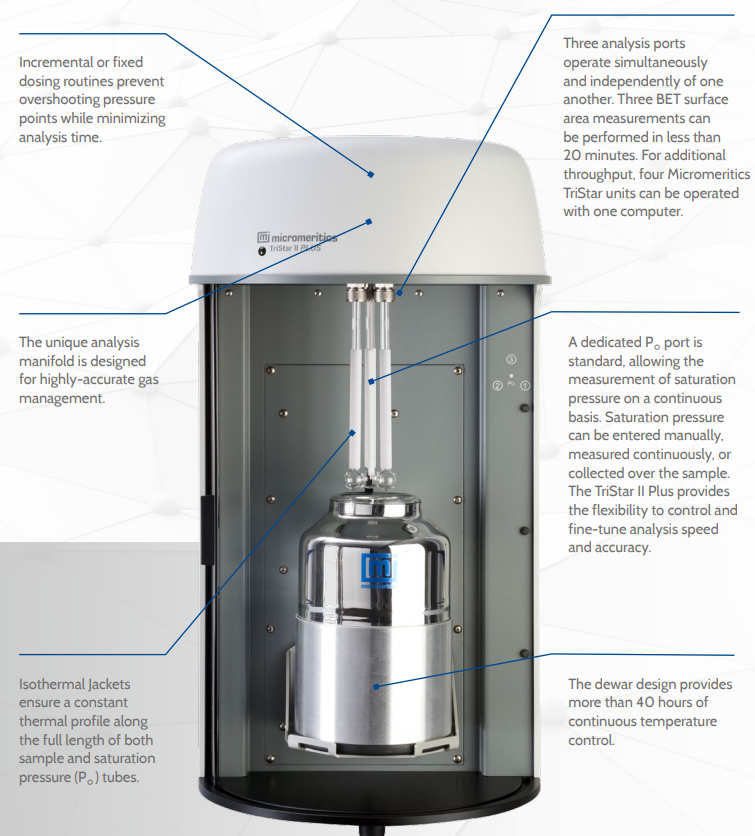

The Micromeritics® TriStar II Plus is a fully automated surface area and porosity analyzer that delivers a rapid high throughput analysis with high accuracy. The three-station unit increases the speed and efficiency of routine quality control analyses, yet has the accuracy, resolution, and data reduction capability to serve research requirements. The instrument combines versatility in analysis methods and data reduction to allow analyses that are customized to application needs.

Features and benefits:

- The TriStar II Plus provides an efficient high throughput system with three sample ports operating simultaneously and independently. For additional throughput, up to four units can be operated with one computer.

- Surface areas as low as 0.01 m2 /g can be measured with the standard nitrogen system. A Krypton Option can extend surface area measurements to as low as 0.001 m2 /g.

- The TriStar II Plus accommodates analysis with a variety of adsorbates including argon, carbon dioxide, and other noncorrosive gases such as butane, methane, and other light hydrocarbons.

- Free space can be measured, calculated, or manually entered providing maximum flexibility in accommodating special sample types and emphasizing speed when needed.

- Isothermal Jackets ensure a constant thermal profile along with the full length of both sample and saturation pressure (Po) tubes.

- Micromeritics MicroActive data reduction and control software enables the user to interactively calculate surface area and porosity. User-selectable data ranges through the graphic interface allow direct modeling for BET, t-Plot, Langmuir, and DFT interpretation.

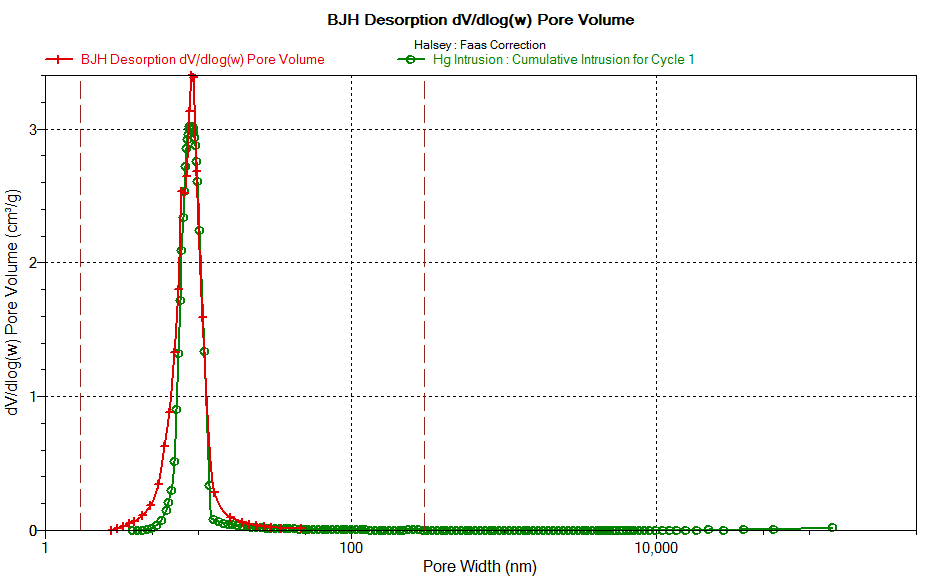

- The enhanced software capabilities allow comprehensive pore size distribution data by gas adsorption & mercury intrusion overlay and advanced NLDFT.

Specifications

Pressure Measurement

| Absolute | Range: 0 to 950 mmHg

Resolution: Within 0.05 mmHg Linearity: < ± 0.1% of span |

| Relative | P/Po range: 0 to 1.0 P/Po Resolution: < 10-4 |

Analysis

| Specific Surface Area | From 0.01 m2/g, nitrogen unit

From 0.001 m2/g, krypton unit |

| Total Surface Area | From 0.1 m2, nitrogen unit From 0.01 m2, krypton unit |

| Pore Volume | From 4 × 10-6 cm³/g |

| Dewar Duration | Up to 40 hours |

| Gas Consumption | Up to 300 cm³ STP per port |

Adsorptive Gases

| Nitrogen Unit | Nitrogen; argon, carbon dioxide, or other non-corrosive gases; butane, methane, or other light hydrocarbon vapors. Oxygen can also be used only with an appropriate vacuum pump. |

| Krypton Unit | Same as nitrogen unit, plus the capability to perform krypton surface area analyses at lower pressures |

The TriStar II Plus should be operated in a properly vented environment when using flammable or toxic gases.

Manifold Temperature

| Accuracy | ±0.25 °C |

| Resolution | Within 0.1 °C |

Vacuum System

| Nitrogen Unit | Must accommodate 20 × 10-3 mmHg or better; uses oil-based or oil-free vacuum pump |

| Krypton Unit | Must accommodate 1 × 10-3 mmHg; oil-free vacuum pump required |

Operating Environment

| Temperature | 10 to 35 °C (50 to 95 °F), operating 0 to 50 °C (32 to 122 °F), non-operating |

| Humidity | 20 to 80% relative, non-condensing |

| Indoor or Outdoor Use | Indoor only Altitude: 2000 m maximum Pollution degree of the intended environment: 2 |

Physical

| Height | 74 cm (29 in.) |

| Width | 40 cm (16 in.) |

| Depth | 51 cm (20 in.) |

| Weight | 37 kg (82 lbs) |

Electrical

| Voltage | 100-240V~ |

| Power | 150VA, maximum |

| Frequency | 50/60Hz |

| Overvoltage category | II |

Technology

Applications

Additive Manufacturing

Surface area is a critical tool in investigating the kinetics of the sintering process and product properties. Particles having rough surfaces or internal porosity will generally exhibit higher specific surface areas. Therefore, surface area indicates the amount of sample surface available to react with other component particles and /or the surrounding environment.

Carbon Black

The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production. Medical Implants Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

Adsorbents

Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

Catalysts

The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

Nanotubes

Nanotube surface area and micro porosity are used to predict the capacity of a material to store hydrogen.

Activated Carbons

Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in wastewater management.

Ceramics

Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

Paints and Coatings

The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness, solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

Batteries and Fuel Cells

Optimizing the surface area and porosity of the components improves storage capacity and energy generation.

Geoscience

Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

Pharmaceuticals

Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bioavailability.

Accessories

Quote AccessoriesSample Preparation Devices

Sample Preparation Devices

Sample Preparation Devices

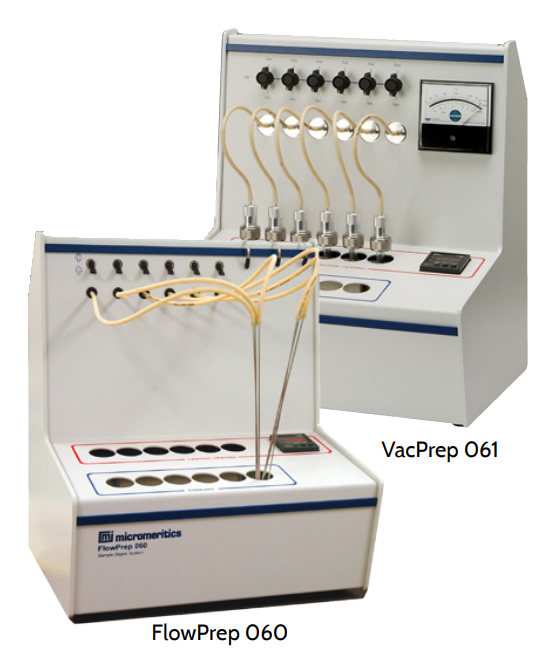

Micromeritics offers numerous sample preparation devices for surface area and pore volume analysis. These devices combine flowing gas and/or vacuum with heat to remove atmospheric contaminants, such as water vapor and adsorbed gas, from the surface and pores of the sample. The quality of the data produced by surface area and pore volume analyses depends greatly on the cleanliness of the sample surface. All of Micromeritics sample preparation devices accept He, N2 , Ar, and other non-corrosive gases.

The FlowPrep™ 060

The FlowPrep™ 060 applies both heat and a stream of inert gas to the sample. The heat causes contaminants to desorb from the surface and the stream of inert gas sweeps them out of the sample tube. The unit lets you choose the temperature, gas, and flow rate best suited for your sample material and application. Needle valves allow you to introduce the flowing gas slowly to prevent fluidization of samples.

The VacPrep™ 061

The VacPrep™ 061 offers two methods for removing contaminants. In addition to flowing gas, it enables vacuum to be applied to prepare samples by heating and evacuation. This combination allows you to choose the preparation method that is best suited to your material or application. The VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations. Needle valves are also provided allowing you to introduce slowly the flowing gas or vacuum to prevent fluidization of samples.

The Smart VacPrep™ 067

The Smart VacPrep™ 067

The Smart VacPrep™ 067 is an advanced six-port system that utilizes vacuum to prepare samples by heating and evacuation. Each of the ports may be operated independently. Samples may be added or removed from degas ports without disturbing the treatment of other samples undergoing preparation. Degassing automatically terminates when the samples have completed all programmed steps.

Cryogen Transfer System

Cryogen Transfer System

Cryogen Transfer System

The Micromeritics Cryogen Transfer System allows transferring liquid nitrogen or liquid argon from a nonpressurized storage dewar into smaller containers used in laboratory experiments. Additional accessories are available for special applications.

Consumables & Supplies

Consumables & Supplies

Software

Enhanced Software Capabilities, Data Reduction, And Instrument Monitoring

MicroActive Software for TriStar II Plus

MicroActive Software for TriStar II Plus

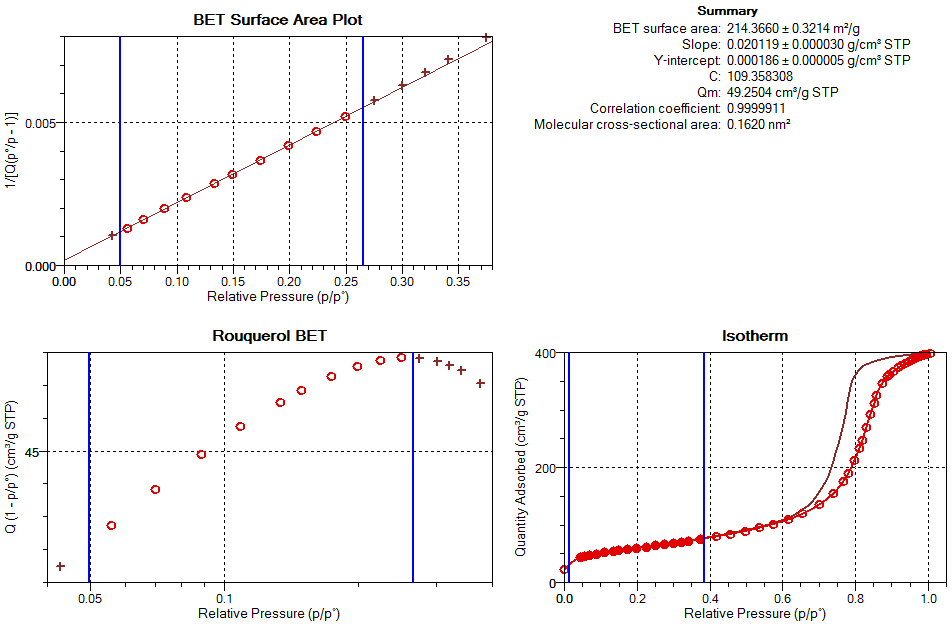

The intuitive Micromeritics MicroActive control software for the TriStar II Plus enables the user to interactively evaluate isotherm data and reduce the time required to obtain surface area and porosity results. It is not necessary to generate reports to view results. Calculations, such as the BET surface area transform plot, can be easily generated, and adjusted. The selection bars allow for a range of data points to be quickly and easily selected. As a result, the summary of values derived from the calculations is instantly updated. Within the calculation window(s),the range of data used can be further refined.

Gas Adsorption and Mercury Intrusion Overlay

Gas Adsorption and Mercury Intrusion Overlay

MicroActive software for the TriStar II Plus also includes a powerful utility that allows the user to overlay a mercury porosimetry pore size distribution with a pore size distribution calculated from gas adsorption isotherms. This import function allows users to rapidly view micropore, mesopore, and macropore distributions in one easy-to-use application

Advanced NLDFT

Advanced NLDFT

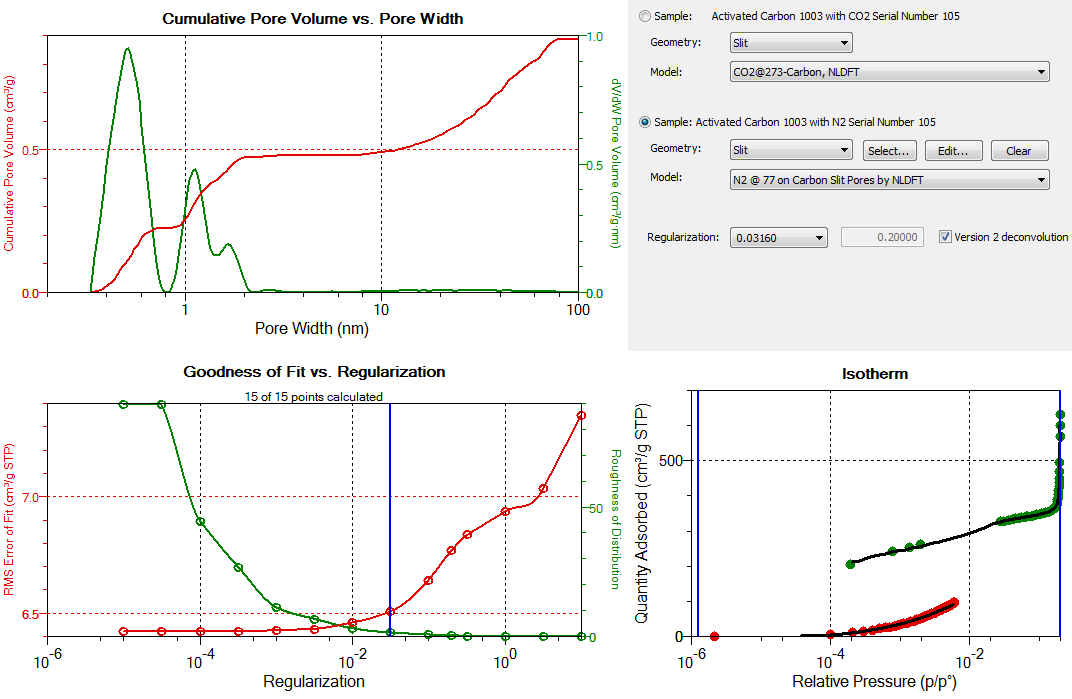

The Advanced NLDFT model allows the user to combine the information gathered from nitrogen and carbon dioxide isotherms to deliver a full pore size distribution on materials (such as carbon slit pores) where pores of molecular sizes are present. The range of pore size analysis in this method is extended to smaller pore sizes compared to the standard nitrogen analysis. This is since CO2 can access some very small micropores that are not accessible to N2 at cryogenic temperatures due to size restrictions, connectivity problems, or extremely slow diffusion

TriStar II Plus Resources

Application Notes

- Performance Testing Porous Aluminas Using the TriStar Surface Area and Porosity Analyzer

- The Measurement of Pharmaceutical Lubricants Using the TriStar II Krypton Option

- The Measurement of Pharmaceutical Binders Using the TriStar II Krypton Option