Powder Flow Properties

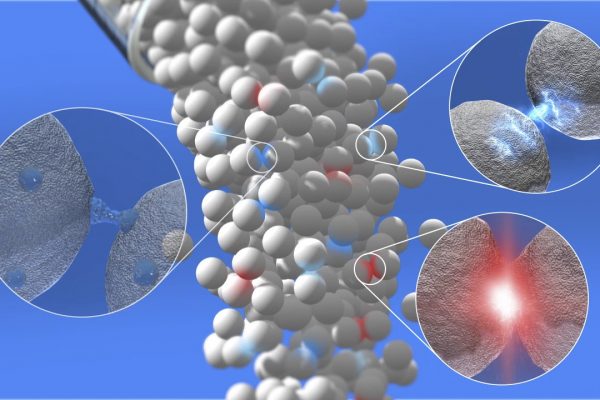

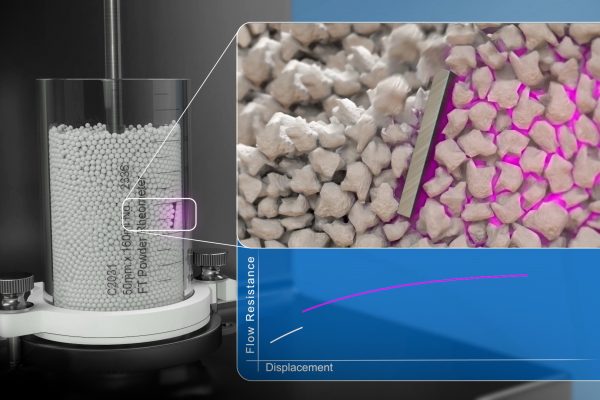

In addition to providing analysis of particle size, shape, surface area, and density, Particle Testing Authority can perform measurements of powder flow properties using the FT4 Powder Rheometer® and provide application support from the experts at Freeman Technology (recently acquired by Micromeritics) based on real-world experience.

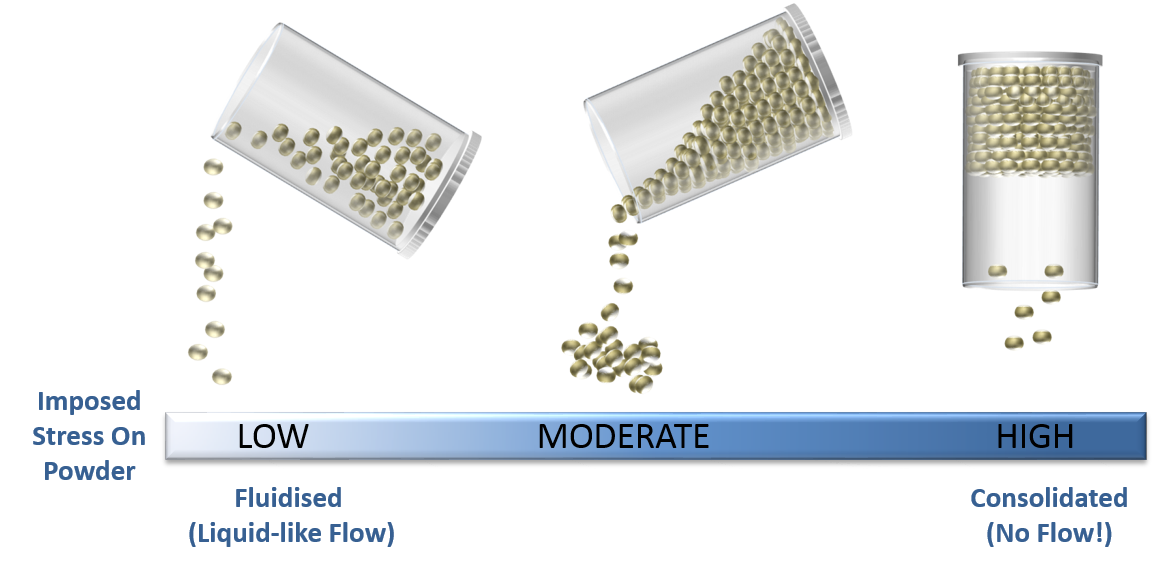

Any organization that incorporates the flow of bulk powders in any part of their process has a lot to gain by measuring and understanding the flow properties of their powders whether it is to optimize a formulation in a development environment, predict in-process performance, understand batch differences, or to ensure the quality of raw materials or intermediates.