The new BreakThrough Analyzer (BTA) is a flexible gas delivery and management system for the precise characterization of adsorbent performance under process-relevant conditions. It delivers reliable adsorption data for gas/vapor mixtures using a flow-through system.

A safe and highly optimized device for collecting both transient and equilibrium adsorption data for multi component systems. The BTA can be configured with up to six precision mass flow controllers and patented high performance blending valves, delivering unparalleled flexibility in experimental design. The superior gas-delivery design ensures the precise control of both composition and flow rate, while minimizing dead volume.

The high-quality, stainless-steel column can hold 0.05 to 2.5 grams of adsorbent. Automated sample activation up to 1050°C is possible with the precise, rugged, and reliable resistance furnace.

Operating pressures are controlled from atmospheric to 30 bar via a servo positioned controlled valve. The thermostated environmental chamber delivers uniform temperature control of the entire system up to 200°C, eliminating cold spots. The BTA secure door lock system ensures operator safety throughout the analysis.

Vapor generators can be added to the BTA to enable the use of important probe molecules such as water for experimental studies. The BTA easily connects to commercially available Fourier Transform Infrared and Mass Spectrometer systems for gas identification and quantification.

Thermostated

Environmental Chamber

Fully Automated Experimental Design

Touch Screen

Proprietary Blending Valves

Up to 6 Gas Inlets and 2 Vapor Sources

Automatic Door Lock

Addition Of Detectors and

G Other Optional Accessories

The BTA offers several advantages over any competitive adsorption measurement system including:

The Micromeritics BTA is capable of flowing up to two vapor streams simultaneously

through its packed column. The thermostated environmental chamber prevents condensation of these vapor streams during analysis and ensures that all gases and

vapors maintain a constant temperature within the instrument. Vapor streams are

generated using a bubbler which allows for a carrier gas to reach saturation with the vapor of choice. The figure below displays multicomponent ethanol/water breakthrough measurements conducted on zeolite 13X.

A safe and highly optimized device for collecting both transient and equilibrium adsorption data for multi component systems.

MicroActive is the most intuitive, flexible, and comprehensive analysis software for adsorption studies

MicroActive Software allows for:

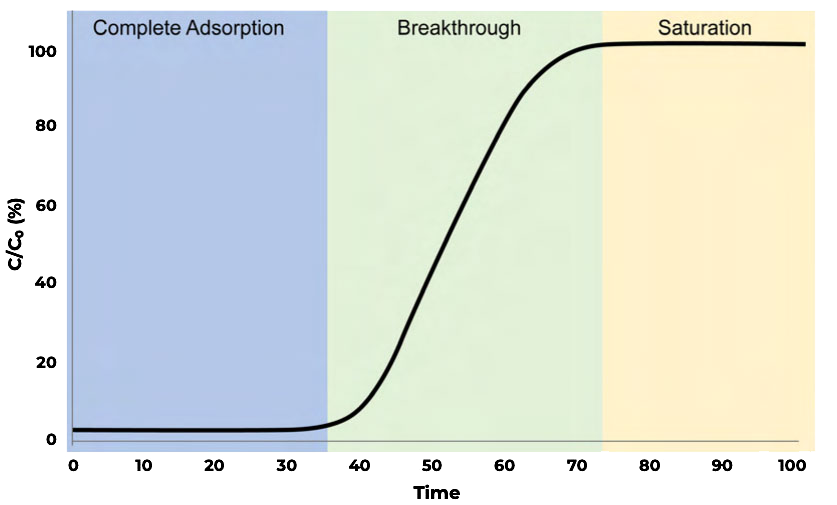

The flexible, intuitive, easy-to-use software allows for the widest range of experimental conditions and automates the breakthrough from sample activation to sample analysis, including the ability to perform cyclic experiments. Paired with industry leading MicroActive analysis software, the BTA system accurately and reproducibly characterizes adsorbents, analyzes data with comprehensive analysis methods, and solves the breakthrough equation for the most demanding samples.

Zeolite 13X has been extensively studied for applications in catalysis and adsorption. In this study, zeolite 13X was used as an adsorbent for carbon dioxide adsorption to collect breakthrough curves from 1 – 10 bar pressure.

These measurements were collected using equimolar flowrates of 10 sccm nitrogen and 10 sccm carbon dioxide. A 1 sccm stream of helium was used as a tracer gas to determine the start of the breakthrough experiment.

All measurements were collected at an analysis temperature of 30°C. Between each measurement, the zeolite 13X sample was reactivated overnight to ensure complete desorption of carbon dioxide. The figure shows a consistent increase in breakthorugh time across successive experiments as the pressure is increased.

Following carbon dioxide breakthrough measurements an equilibrium adsorption quantity was calculated for each curve by solving the breakthrough equation. Next, an isotherm was constructed displaying the quantity of carbon dioxide adsorbed at 1, 2, 3, 5, 7, and 10 bar total pressure. At 10 bar, zeolite 13X adsorbed roughly 15 mmol/g carbon dioxide. While isothermal data collected via breakthrough cannot be directly correlated with static adsorption measurements, it can provide a assessment of an adsorbent in process relevant conditions.

Multicomponent adsorption studies often require a mass spectrometer (MS) to monitor the residual gas composition. The MS is the most common detector system used for breakthrough analysis.

FTIR spectrometers are often selected for experimental breakthrough studies such as the separation of xylenes or other aromatic hydrocarbons.

Allows direct tracking of water content for low cost. Can be useful especially in production control applications.

Small quantities of active material can be mixed with an inert carrier to produce a homogeneous sample and improve analysis reproducibility.

Allows direct tracking of CO2 content for low cost. Can be useful especially in production control applications.

Additional mass flow controllers and blending valves may be added to the BTA to increase the analytical capabilities and expand the range of experiments that may be conducted.

The BTA may be used with a variety of column diameters to accommodate different sample morphologies included powders, pellets, and extrudates.

Moisture or other vapors such as xylenes or other aromatics are compatible with the optional vapor sources available for the BTA.

Special inert materials of construction enable simulation of process conditions – such as post-combustion CO2 capture – that include highly reactive gases like NOx, H2</subS, or SO2</sub.

Natural gas is a mixture of hydrocarbons and other gases that must...

+DAC is difficult due to low concentrations of carbon dioxide in air...

+Power generation, chemical plants, and refineries are significant point sources for carbon...

+Are a core part of the petrochemical industry and used to in...

+Porous solids are used for personal protection and also under development for...

+Harvesting water from the air may be a critical technology for many...

+Pressure swing adsorption using Zeolite 5A, 13X, or LiX, which have high...

+Amine functionalized silicas are effective and highly selective adsorbents and used for...

+Porous membranes and monoliths coated zeolites or MOFs are commonly used to...

+Volatile organic component (VOC) from automobile fuel systems are captured by canisters...

+Alumina – Supported Ionic Liquids are effective adsorbents with potential applications for...

+MOFs are highly selective adsorbents which are effective for demanding commercial applications...

+| Furnace Temp Max | 1050°C |

| Thermostated environmental chamber Temp Max | 200°C |

| Sample Mass | Up to 2.5 g |

| Sample Volume | Up to 2.5 mL |

| Determination of breakthrough curves | Programmable total pressure, flow rate, composition and temperature |

| Investigation of kinetic performance of adsorbents | Optimised for research-scale sample sizes with interchangeable reactor beds |

| Investigation of co-adsorption and displacement | Ultra-low dead volume for rapid signal response |

| Determination of sorption selectivity | Automated switching between purge and process gases |

| High-resolution separations using small sample quantities | Configurations for gas-vapor and vapor-vapor separation |

| Dynamic adsorption and desorption experiments | Door remains locked during analysis to protect user and the analysis from altered temperature conditions |

| Determination of single- and multi-component adsorption data | Touch Screen |

| In-situ sample preparation up to 450°C with a SS column and 1050°C with a quartz column | Patented “No Dead Volume” mixing valve with rapid switching |

| Fully automated control via PC | Up to 6 high precision mass flow controllers |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Request a quote or talk to an expert for more information