Micromeritics is known worldwide as the leader in manufacturing reactors at different scales to suit any catalytic processes

A reactor, widely used in industry and research institutes, is capable of holding a catalyst that can carry out a chemical reaction at elevated temperatures and pressures. By using a catalyst, the activation energy is lowered, increasing the rate of reaction without altering the final products. The setup of a reactor is crucial for understanding and improving a catalyst’s activity and selectivity, ultimately enhancing the efficiency and final yield of the catalytic process.

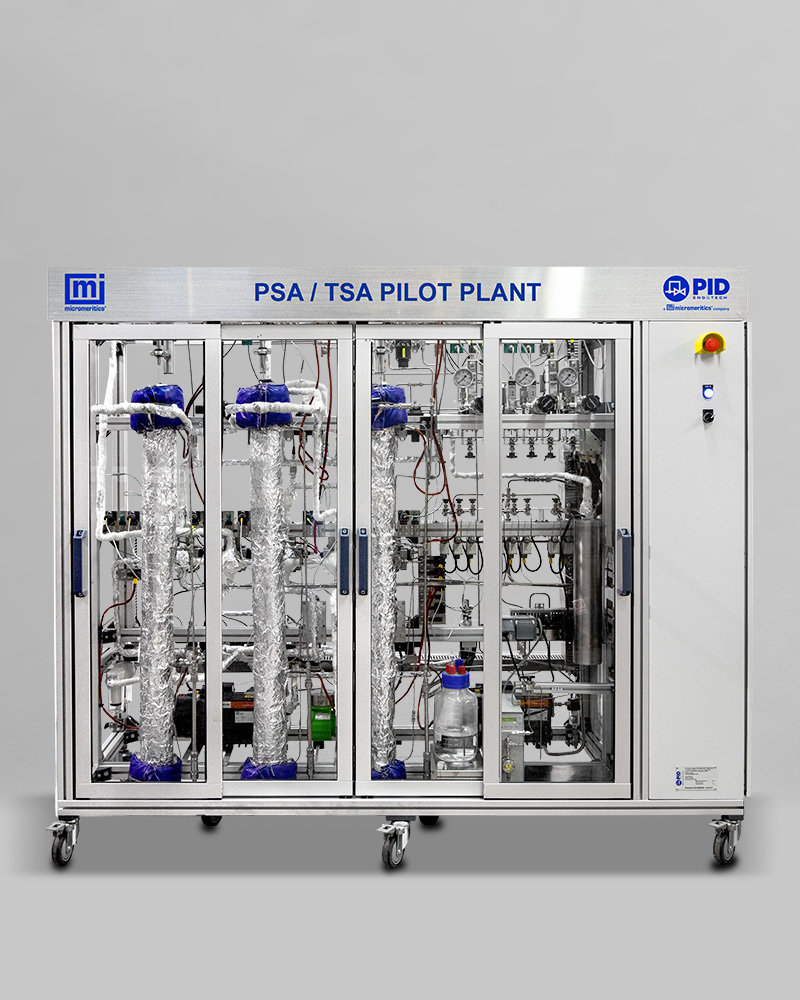

Reactors can be as small as microreactors and hold a few milligrams of sample up to several grams of catalysts when upgraded to pilot plants. All FR microreactor series operate up to 100 bar of pressure and up to 1050℃ of temperature.

Steam methane reforming (SMR) is a process in which natural gas is heated with steam to produce a mixture of carbon monoxide and hydrogen.

The FR includes multiple levels of safety features that make the system simple to deploy and safe to operate. Additional safety features such as automatic shut-off valves and gas detectors are available to add as appropriate.

Simulate industrial processes at a laboratory scale for product development, quality improvement, and process innovation.

Expertise in instrumentation and control ensures reliable and reproducible results in complex systems.

The Micromeritics in-situ Catalyst Characterization System (ICCS) is an advanced catalyst characterization tool that allows the user to study the impact of a reaction on critical parameters such as number of active sites, under precisely controlled, process-representative conditions.