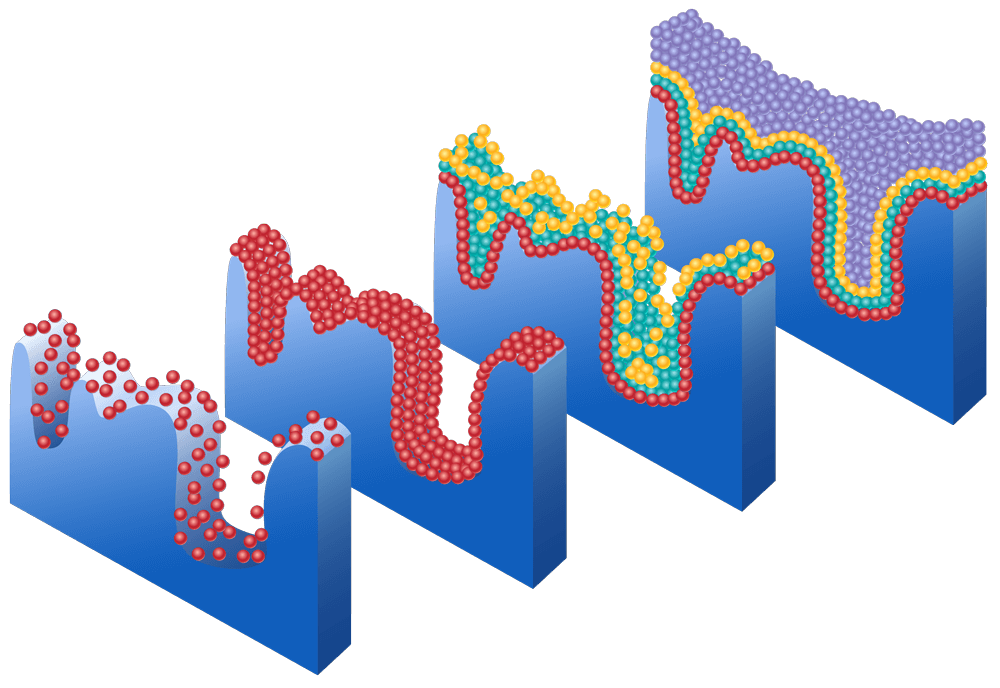

AutoPore V

The AutoPore V Series Mercury Porosimeters can determine a broader pore size distribution more quickly and accurately than other methods. This instrument also features enhanced safety features and offers new data reduction and reporting choices that provide more information about pore geometry and the fluid transport characteristics of your material.