Introduction

Specific Surface Area and the Pore Volume Distribution of materials are frequently determined from the adsorption isotherm, which is the quantity of gas that is adsorbed onto the surface and within the pores of a material as a function of pressure above the sample. These analyses are frequently conducted at cryogenic temperatures to enhance the adsorption process. These isothermal results are generally normalized for the mass of sample under test.

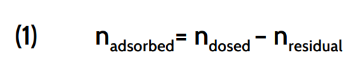

The adsorption isotherm is obtained by measuring pressure and temperature. These values and the calibrated system volume, the manifold volume, are used to determine the quantity of gas transferred from the manifold to the sample tube. This value is commonly referred to as the quantity dosed (ndosed). Also from pressure and temperatures, the residual quantity (nresidual) in the gas phase of the sample tube may be calculated. Knowing the quantity dosed and the residual quantity, a simple molar balance is employed to obtain the quantity adsorbed (nadsorbed) as shown in equation (1).

The free space (or void space) is required to calculate the residual quantity.

There are three methods available in the Micromeritics gas adsorption analyzer software to obtain the required free space values:

- Measured,

- Entered

- Calculated

These are discussed and compared in this Application Note.

Measured Free Space

Measured free space is the fully automated method that uses pycnometry to determine the empty volume of the sample tube. The simplest means to determine the two free space values is to measure it with the sample in place, since the sample will occupy space in the sample holder. Since helium does not generally adsorb onto many materials, it is usually the gas of choice for measurement of the free space values. The instrument manifold and sample holder are evacuated, then the manifold is filled with helium to a measured pressure, frequently just above atmospheric pressure. The manifold temperature is also recorded, from which the amount of gas in the manifold is determined.

The valve that connects the manifold to the sample holder is opened, allowing gas to expand into the tube. The final pressure is measured, along with the temperature of the manifold. The gas law is used to determine the volume of the sample holder, which is corrected to atmospheric pressure and standard temperature. Thus the warm or ambient free space is recorded in terms of gas volume at STP.

The analysis bath is raised up around the sample holder, and the pressure is measured again, once time has been allowed for thermal equilibration. This pressure is then used to determine the cold or analysis free space, again expressed at STP. These two free space values, the ambient and analysis, can then be used to determine the portion of the free space at analysis bath temperature, to which compressibility correction can be applied.

Again, this is the most direct means for calculating the free space values needed to determine the volume of gas adsorbed by the sample. So long as the helium does not interact with the sample, this is the most reliable means. Since helium generally does not adsorb appreciably at these temperatures, direct measurement using helium can be used for most analyses. Note that helium does penetrate inside the open pores of the sample, and if these pores are very small micropores, the helium may be difficult to remove quickly. It can diffuse out of the sample pores slowly over time, even after evacuation of the sample, and cause errors in the isotherm at very low absolute pressures. For these samples, the free space can be measured after the analysis, or as part of a preliminary test after which the sample is degassed again. Another choice is to calculate the free space values, as will be discussed below.

In addition to these rare sample related problems, note that another disadvantage of direct measurement of free space, though more accurate, is that it does take time and use helium for each sample analysis. Recently the price of helium has increased, while its ready supply has decreased. Therefore, a means that will minimize the amount of helium required, and reduce the sample analysis time, may be advantageous. Such a technique is to calculate the free space values.

Calculated Free Space

The difference between the free space of an empty sample holder, and one that contains a sample, is the space occupied by the sample, and the subsequent volume of gas that it displaces. The relationship between the volume a sample occupies and the amount of sample is the density of the material. Since the amount of gas displaced by the sample is needed, the skeletal density of the sample is what is used in this case. That is the mass of the sample divided by its skeletal volume, which is the volume of the sample itself, less any open porosity, as the volume in the open porosity does not displace gas, though the volume of closed porosity is included in the skeletal volume. This skeletal density is that which can be determined using a gas pycnometer such as the Micromeritics AccuPyc II.

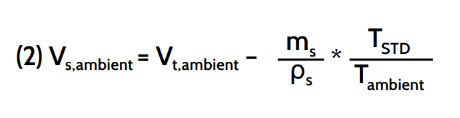

Thus if the free space values of the empty sample holder are known, through a standard free space measurement without sample present, it can be corrected at the time of analysis for sample volume through the use of the sample mass and skeletal density. The cold or analysis free space receives a larger correction than the warm or ambient free space as the sample displaces more gas at analysis temperature than it does at ambient temperature, assuming of course the analysis is carried out at sub-ambient temperature. The sample volume is simply multiplied by ratio of ambient temperature to bath temperature for the correction to the analysis free space. All other calculations are the same as with direct measurement of the free space, including correction for gas compressibility. Both ambient and analysis free space values are reported in terms of standard gas volume, that is the volume of gas corrected to standard temperature and pressure (STP), and so both free space values are corrected to standard temperature, 273.15K. Equation (2) is used to calculate the sample ambient free space (Vs,ambient) from sample mass (ms), sample skeletal density (ρs), ambient temperature (Tambient), standard temperature (TSTD), and the measured empty tube ambient free space (Vt,ambient).

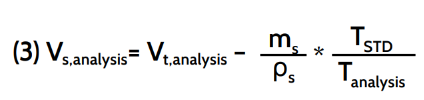

Equation (3) is used to calculate the sample analysis free space (Vs,analysis) in similar manner using the analysis temperature (Tanalysis) and the measured empty tube analysis free space (Vt,analysis). Note that ambient and analysis free space refers to the temperature of the sample tube when the free space value is determined.

Note that all Micromeritics physisorption analyzer software perform these calculations automatically. The Operator only needs to transfer the two free space values determined for the empty sample tubes into the sample information file for the sample analysis, along with the sample mass and skeletal density.

Calculated free space offers two distinct advantages over direct measurement. First, free space only needs to be determined once for the empty sample tubes, removing any requirement for helium usage for each sample analysis. Second, the time to perform the free space determination is saved for each sample analysis as the calculation of free space takes microseconds of computer time. These calculated free space values are not always as accurate as directly measured ones, and so there is more potential blank error in analysis results when calculated free space is used. So long as the sample adsorbs a significant amount of gas, any blank error is insignificant. Note, however, that direct measurement of free space over the sample is more accurate.

All of the Micromeritics static (manometric) instruments are designed for easy usage of calculated free space. Simply analyze empty sample holders, with any filler rods or CheckSeals installed, along with isothermal jackets. The use of the isothermal jacket will reduce blank error when using calculated free space values since it will maintain a constant height of cryogen on the sample tube when measuring the free space of the empty sample holder, and then when using it during subsequent sample analysis with calculated free space values. Note that the volumes of filler rods and CheckSeals vary slightly, and so for best results, keep any of these components matched to the sample tube when using calculated free space values.

Once the free space values are determined for the empty sample holder, along with any additional hardware used, these values can be entered into the sample information file for the sample analysis directly from that for the empty sample holder, or through manual entry by the operator. The sample skeletal density can be entered into the sample information files, generally in a field adjacent to the sample mass. Simply indicate that calculated free space is to be used in the analysis conditions section of the sample information file, and start the analysis. All other analysis parameters should be the same as would be used with direct free space measurement. The result will be a quicker analysis than when free space is measured, and no helium usage during the individual sample analyses.

Entered Free Space Values

There is another means for applying a known free space to a sample analysis. That is through manual entry of the free space determined over the sample from, for instance, a previous analysis of the same sample. Such is often used when characterizing microporous materials, as mentioned above. A brief analysis is performed with direct free space measurement, then the sample is degassed again to remove any residual helium, followed by the final, complete, analysis. This prevents helium diffusion out of the sample pores from interfering with isotherm results. In addition, if a sample is analyzed repeatedly, say after different treatment schemes, the free space values from an initial analysis can be entered into any subsequent analyses.

Example of Calculated Free Space for an Analysis Using the TriStar II Plus

Note again that all static (manometric) analysis instruments produced by Micromeritics include the means for using calculated free space values as described above. An example comparing analyses using measured free space determination with those using calculated free space values is given here for the TriStar II Plus. Similar results should be expected from any of the Micromeritics instruments.

The specific surface area of a sample of porous alumina catalyst support is needed. The sample is to be analyzed in duplicate using a Micromeritics TriStar II Plus. Prior to loading with sample, free space values were directly determined for the two empty sample holders. Note that due to instrument design and controlling software, it is possible to determine the free space of the empty sample tube on any port of the TriStar, and then use the sample tube for sample analysis on any other port, even on another TriStar.

After analysis of the empty sample holders, approximately 0.25 g of catalyst support was placed into each, and the samples were degassed under flowing nitrogen for 4 hours at 350 °C. A sample information file was prepared for each of the two samples, to determine the nitrogen adsorption isotherm over a relative pressure range of 0.05 to 0.25, from which the BET multipoint specific surface area was determined. For this first analysis, free space was calculated, using the free space values determined for the empty sample holders, along with the sample mass and sample skeletal density. A skeletal density of 3.604 g/cm3 for this material was determined using the Micromeritics AccuPyc II.

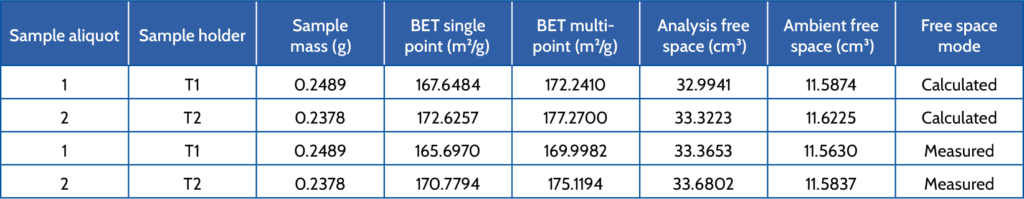

After this initial analysis performed with calculated free space, a second analysis was performed for both samples, this time with all parameters the same except that free space was measured over the sample using helium. Table 1 contains the determined BET specific surface area, single point and multipoint, for the two analyses of the two samples, along with the degassed sample mass, and the ambient (warm) and analysis (cold) free space values for each analysis.

Note that there is more difference between results for the two aliquots of the sample than between the two analyses of either aliquot. The difference between results for one aliquot using the two different free space modes is about 1%, while the difference in results between the two different aliquots is about 3%, due to slight variation in the material.

Thus, essentially the same results can be determined when calculating the free space using sample mass and the empty-tube free space values as compared to direct measurement of the analysis free space. Using calculated free space values saves both time and helium for each sample analysis once the free space of the empty sample holder has been determined.