Introduction

Selective Laser Sintering (SLS) is an additive manufacturing technique typically used for rapid prototyping and low volume production of functional components. The process employs a laser beam to sinter powdered material, binding it together to create a solid structure. The laser selectively fuses pre-defined areas of a powder bed by scanning cross-sections generated from a 3D digital description of the required part. After each cross-section is scanned, a new layer of material is applied on top, and the process is repeated until the part is completed.

Generating the layers of powder is a precision process and requires a feedstock that can be reliably distributed by the delivery system and that is deposited on to the fabrication bed in a consistent manner without agglomerates or voids. Intermittent flow, or agglomerates within the bulk, will cause non-uniform deposition, adversely affecting the efficiency of the process and the properties of the final product. Identifying which powder properties are conducive with the formation of uniform, repeatable layers allows new formulations to be optimised, and suitable raw materials identified, without incurring the significant financial and time overheads associated with running materials through a process to assess compatibility. This approach also helps reduce the occurrence of final products that are out of specification.

The Effect of Different Additives

Three samples of Polyoxymethylene (POM), two of which contained different additives (a pigment and a lubricant) were used in an SLS machine. It was observed that the three formulations flowed differently from the storage hopper into the machine resulting in variation in the properties and quality of the final product. A range of traditional characterisation techniques had been employed, but did not provide differentiation between the samples. The three formulations were therefore analysed using an FT4 Powder Rheometer®, which revealed clear and repeatable differences between them that rationalised in-process performance.

Test Results

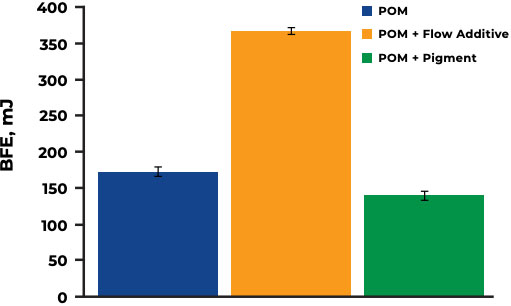

Dynamic Testing: Basic Flowability Energy

The sample containing flow additive generated a higher Basic Flowability Energy (BFE) than the other two samples, requiring more energy to move the FT4 blade through the powder bed. In this case, high BFE is an indicator of more efficient packing within the bulk, and suggests that the addition of the flow additive has resulted in a more freeflowing material.

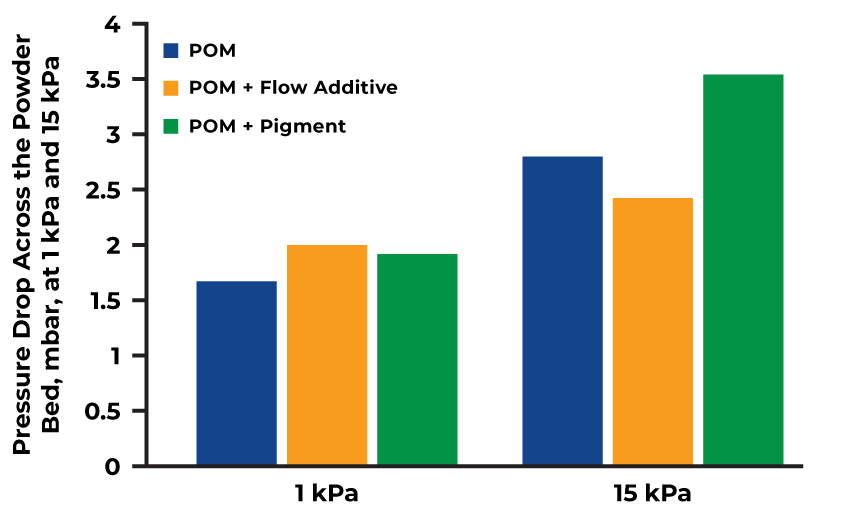

Bulk Testing: Permeability

The sample containing flow additive generated the highest Pressure Drop Across the Powder Bed at a low consolidating stress, indicating reduced permeability and reflecting the denser packing state of this freer-flowing material. While the Pressure Drop for all three samples increased under greater consolidation, the pure POM and the sample containing pigment exhibited a far greater change than the sample containing flow additive.

Low sensitivity to a change in consolidation is a further indicator of a more efficiently packed bulk, i.e. there are fewer air voids for the particles to move into when subjected to an external force. The permeability of the sample containing pigment changed to the greatest extent, suggesting a larger volume of entrained air within the bulk indicative of higher cohesivity.

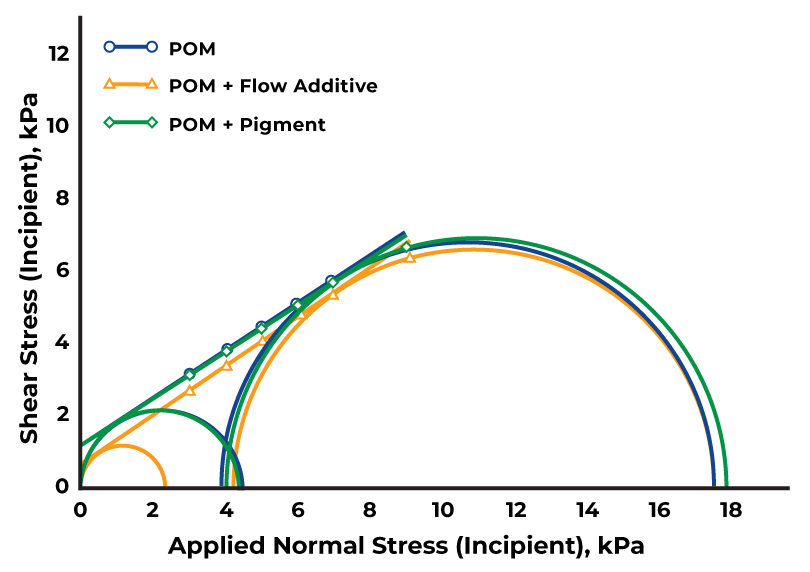

Shear Cell Testing

Limited differentiation was observed between the samples in terms of measured Shear Stress values. This suggests that Shear Cell testing may not be the most relevant technique for characterising flow properties in the low stress, dynamic processes that prevail in SLS applications.

Conclusion

The FT4 has quantified clear and repeatable differences between three samples known to behave differently in process. The results also demonstrate that a single technique (such as Shear Cell testing) may not be sufficient to fully describe powder behaviour across a range of stress and flow regimes.

Powder flowability is not an inherent material property, but is more about the ability of powder to flow in a desired manner in a specific piece of equipment. Successful processing demands that the powder and the process are well-matched and it is not uncommon for the same powder to perform well in one process but poorly in another. This means that several characterisation methodologies are required, the results from which can be correlated with process ranking to produce a design space of parameters that correspond to acceptable process behaviour. Rather than relying on single number characterisation to describe behaviour across all processes, the multivariate approach of the FT4 simulates a range of unit operations, allowing for the direct investigation of a powder’s response to various process and environmental conditions.