Introduction

In spray coating applications, a fine powder, typically a polymer, is drawn from a storage device before being fluidised and ejected through a charged nozzle onto a substrate. It is essential that the powder can be effectively and consistently fluidised, without the formation of agglomerates that may block the nozzle and affect the charging of the individual particles, leading to poor adhesion or the formation of agglomerates on the substrate. It is also essential to establish a smooth flow from the storage device, as erratic flow into the fluidisation chamber will lead to a poorly fluidised bulk.

Identifying and quantifying which powder properties correlate with the most efficient performance in a process allows new formulations to be optimised without the significant cost of running samples through the process to assess suitability, making considerable savings in terms of time and raw materials, and minimising wastage due to rejected products.

Variations in Process Performance and Product Quality

Three samples of a polymer powder were used in a spray coating application using a corona charging system. Sample A exhibited good performance in terms of flowing through the nozzle and adhering to the substrate, and Sample B showed acceptable behaviour, but Sample C was poor in both aspects; causing blockages in the nozzle and subsequently falling away from the substrate during transportation to the kiln. Particle size analysis concluded that all three powders had the same D50 and size distribution.

Samples from the three batches were analysed using an FT4 Powder Rheometer®. Clear and repeatable differences were observed between the samples in multiple tests, rationalising the variation in performance and allowing future batches to be screened prior to introduction to the process.

Test Results

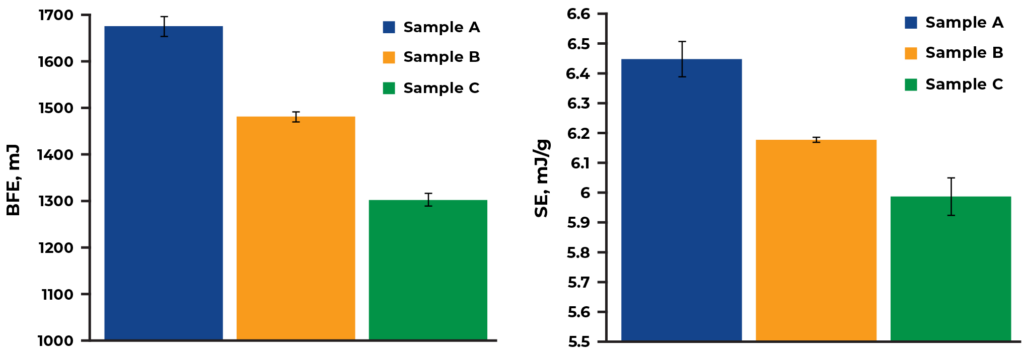

Sample A generated the highest Basic Flowability Energy (BFE) and Specific Energy (SE) of the three samples, which together indicate greater cohesion and particle-particle interlocking. Sample C generated the lowest BFE and SE, suggesting that a degree of inter-particular cohesion is required to form a uniform coating on the substrate, and that Sample C does not meet this criterion.

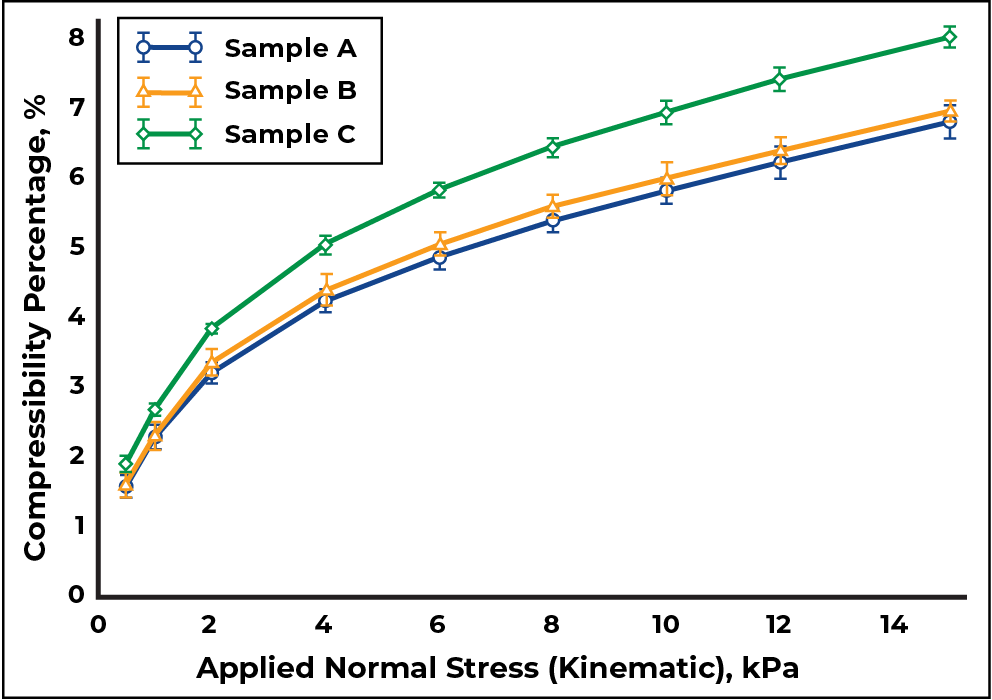

Bulk Testing: Compressibility

Sample C was the most compressible of the samples, indicating a greater propensity to compact under forced flow conditions, such as when drawing the powder from the storage vessel into the fluidisation chamber. The greater propensity to compact will promote the formation of agglomerates, inhibiting both the spraying and charging operations in the nozzle.

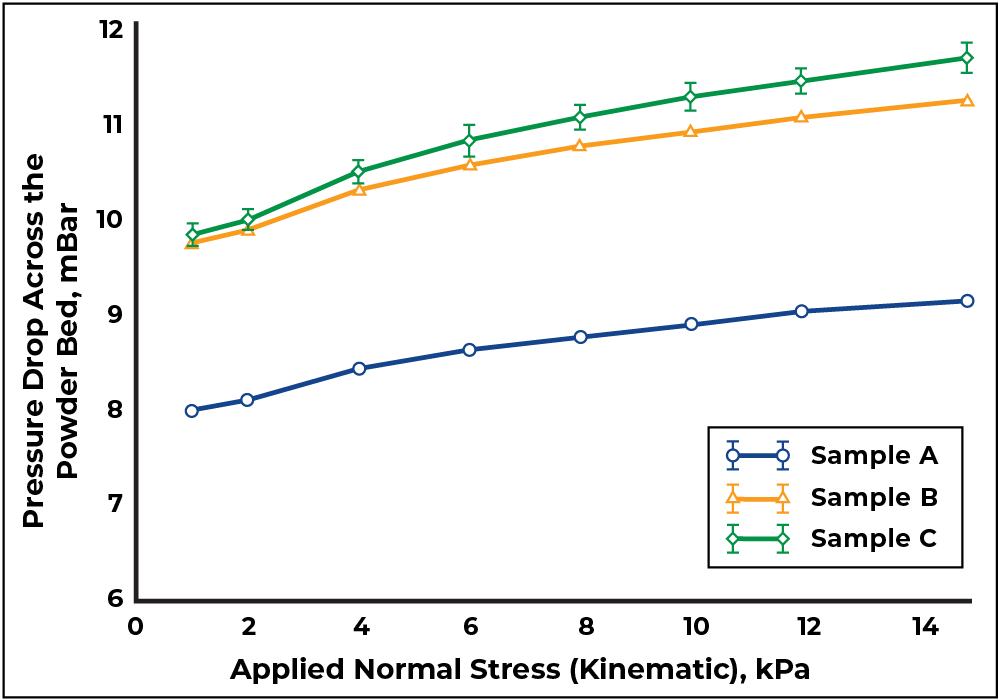

Bulk Testing: Permeability

Sample A generated the lowest Pressure Drop across the Powder Bed indicating that it is the most permeable. This suggests that it will be the most free-flowing under conveyance, and that once fluidised, is likely to flow more readily within an air stream. Sample C was least permeable, generating the highest Pressure Drop across the Powder Bed, which is likely to cause more erratic, pulsatile flow into the fluidisation chamber, and unstable flow of the fluidised mass.

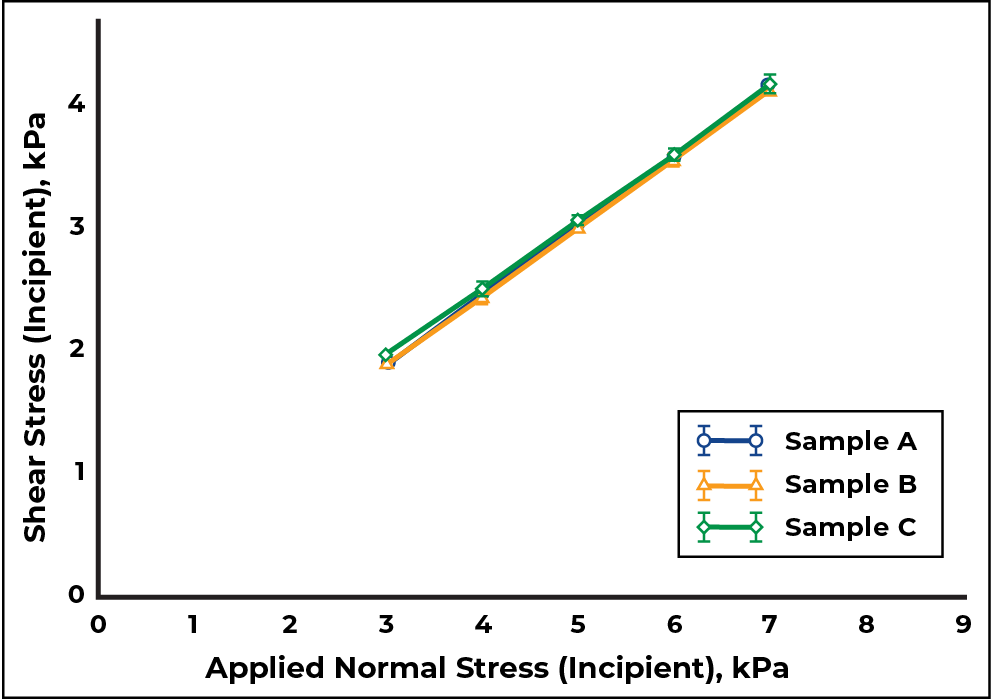

Shear Cell Testing

No differentiation was observed during Shear Cell testing, with the measured Shear Stress values of the three samples identical to within an RSD of 2.5%. The lack of correlation with the process performance indicates that the highly consolidated, low-flow environment of the Shear Cell test is not indicative of behaviour in the dynamic, aerated environment of a fluidisation operation.

Conclusion

The FT4’s multivariate approach has identified clear and repeatable differences between the three powder samples in terms of Dynamic and Bulk properties, which correlate well with in-process performance. Furthermore, the results demonstrate that Shear Cell testing alone does not provide a reliable representation of powder behaviour in this process, due to the differing stress and flow regimes present. Sample A has the highest BFE, SE and Permeability, and the lowest Compressibility, of the three samples. This suggests that a degree of cohesion is required to form a uniform coating but susceptibility to agglomeration and erratic flow is problematic to the process. Sample C, with the lowest BFE and Permeability, and the highest Compressibility, is most sensitive to compaction during conveyance to the fluidisation chamber, forming agglomerates that can block the nozzle and cause inconsistent charging.

Powder flowability is not an inherent material property, but is more about the ability of powder to flow in a desired manner in a specific piece of equipment. Successful processing demands that the powder and the process are wellmatched and it is not uncommon for the same powder to perform well in one process but poorly in another. This means that several characterisation methodologies are required to fully characterise powder behaviour in a range of operations, and rather than relying on single number characterisation to attempt this, the FT4’s multivariate approach simulates a range of unit operations, allowing for the direct investigation of a powder’s response to various process and environmental conditions.