Many materials in the food, chemical and pharmaceutical industries, from raw materials, additives and intermediates through to manufactured products, are supplied as relatively free-flowing powders suitable for the manufacturing process or final application. These materials are often stored for extended periods, during which time some powders will gain strength due to particle/particle interactions. This is generally referred to as ‘caking’ and can significantly limit the ability of a powder to pass through the process train without interruption and can detrimentally impact product quality.

Caking occurs through one or more mechanisms – typically, mechanical, chemical and thermal – with the migration and absorption of water often the most influential. Limiting caking can be achieved by managing environmental conditions to keep materials in an optimal state; by adjusting the operational parameters (typically limiting the time the material is stationary) or by modifying the product formulation.

Through testing and understanding the behaviour of each material, it becomes possible to assess and minimize the risk of caking at different points in the process, to maximize and maintain product quality. Powder testing results can inform, for example, decisions about how often the material needs to be tumbled or agitated to keep it in a fit state for subsequent processing, and whether it can maintain its quality if packed in bags, kegs, bulk containers or tankers.

Regardless of the mechanism, however, determining the precise conditions which minimise the potential for caking requires a comprehensive understanding of the changes in flow properties that occur as a consequence.

The FT4 Powder Rheometer is a universal powder tester that provides automated, reliable and comprehensive measurement of bulk material characteristics. This information can be correlated with process experience to improve processing efficiency and aid quality control. Specialising in the measurement of dynamic flow properties, the FT4 also incorporates a shear cell, and the ability to measure bulk properties such as density, compressibility and permeability.

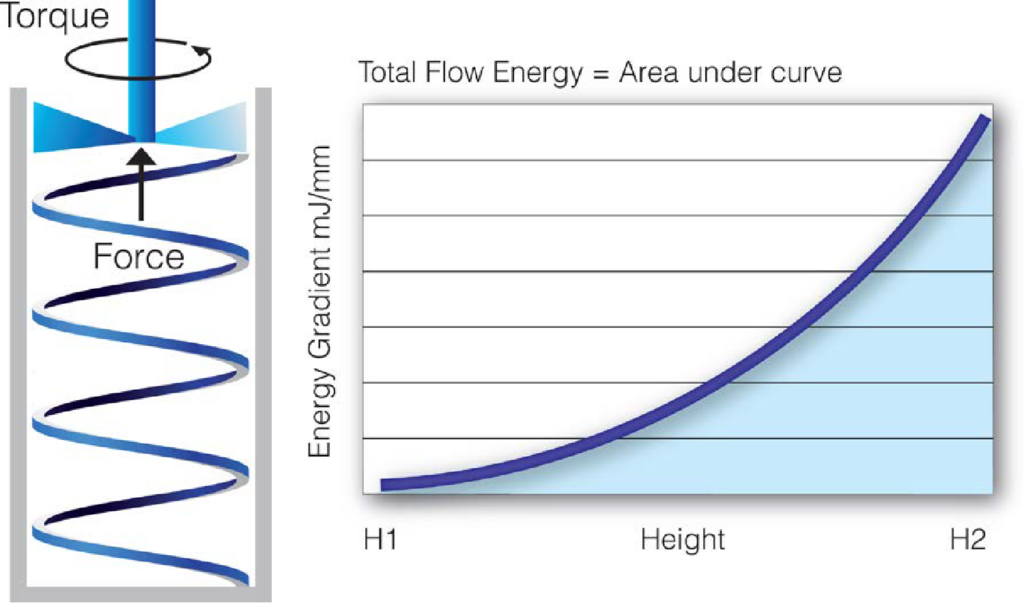

In this study, the dynamic method was used to measure the flow energy of powder samples before and after caking to quantify changes in flowability. Flow energy is determined by means of a patented measurement principle that evaluates the resistance to the motion of a specially shaped blade moving along a prescribed path through a precise volume of powder. The resulting torque and force measurements are converted into a flow energy[1].

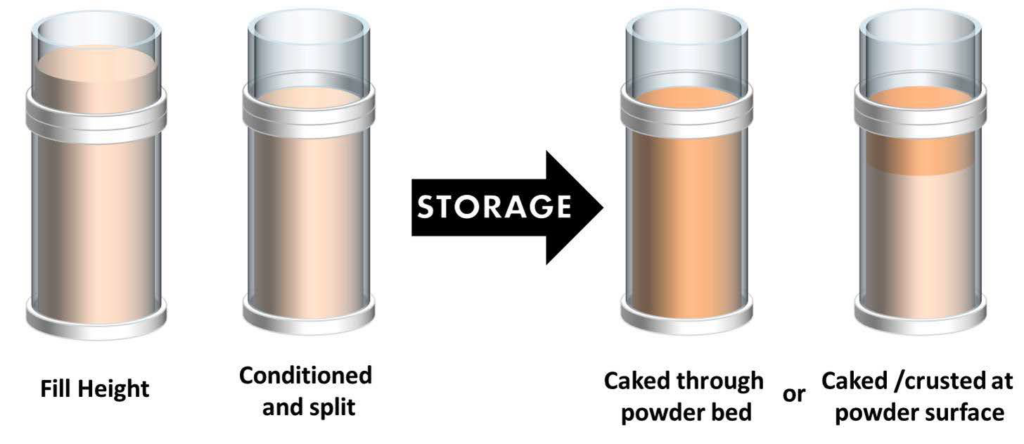

Samples are prepared by filling a test vessel with powder, and using the bespoke Conditioning cycle to generate a uniform packing structure. The vessel is then split to ensure a fixed sample volume which is then stored under the desired conditions.

Most of the powders experience an increase in their resistance to flow through the creation of stronger inter-particulate bonds. In some instances, these changes are reversible, but in many cases the powder has undergone surface changes that result in permanent bonds being created.

Humidity-Enhanced Caking

The effect of humidity on powders is complex due to the interaction of several factors. Moisture adsorption creates capillary bridging, which increases the size of any forces required to separate individual and groups of particles from each other. Over time, adsorbed moisture can also result in solid bridging, facilitated chemical interactions, and increased plastic deformation through increased molecular mobility primarily at particle surfaces.

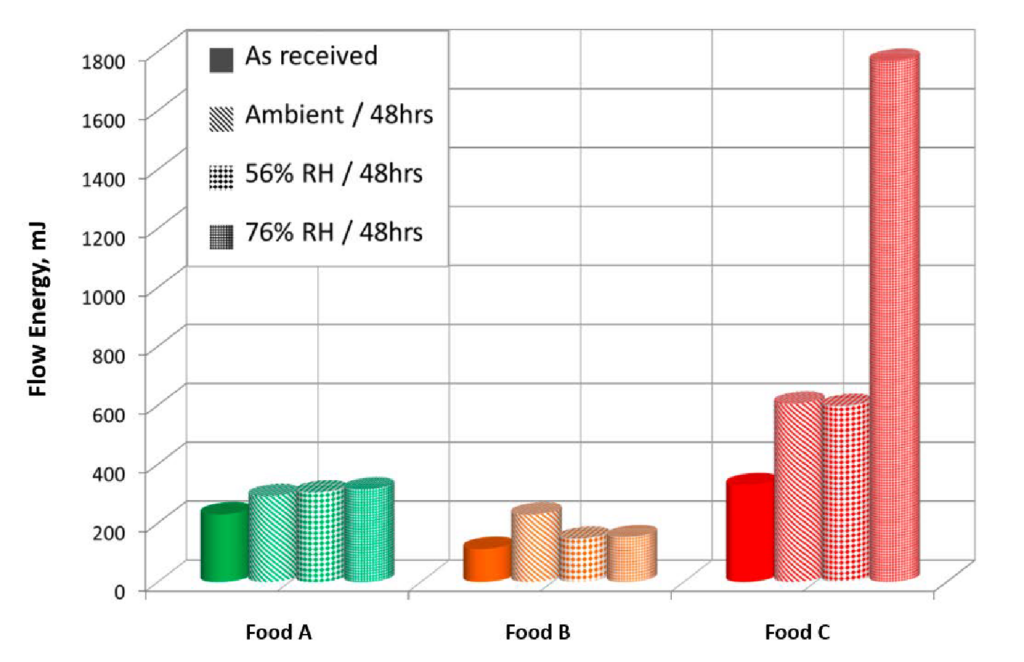

Samples of three different food powders were stored for 48 hours at different relative humidities (RH), and then tested using the FT4 to investigate how each would respond to the conditions, in terms of the Flow Energy required to drive a blade through the bed in an established flow pattern.

The Flow Energy for Food A only marginally increased with increasing RH, indicating that this sample was largely unaffected by the environment. In contrast, Food C exhibited a sharp increase in Flow Energy at 76% RH, likely due to the presence of sucrose crystals partially dissolving in the high humidity and forming strong bridges between particles. Higher Flow Energy represents the powder becoming more difficult to move in dynamic processes, with Food C likely to be more problematic if stored for extended periods at high humidity levels.

Food B showed a different trend, demonstrating that moisture uptake is not always detrimental. A decrease in Flow Energy was observed at 56% RH compared with the ambient sample. Adsorbed moisture can reduce electrostatic forces, and in some cases, surface moisture can act as a lubricant, reducing the strength of the particle interactions. Samples are prepared by filling a test vessel with powder, and using the bespoke Conditioning cycle to generate a uniform packing structure. The vessel is then split to ensure a fixed sample volume which is then stored under the desired conditions. Most of the powders experience an increase in their resistance to flow through the creation of stronger inter-particulate bonds. In some instances, these changes are reversible, but in many cases the powder has undergone surface changes that result in permanent bonds being created.

Non-Homogenous Caking (Crusting)

Caking due to exposure to high relative humidity does not always occur uniformly throughout a given powder. In a number of instances, caking can occur predominantly at the powder surface-air interface, resulting in a strong ‘crust’ which is substantially more resistant to flow compared to the remainder of the powder bed. Quantifying the extent to which this ‘crust’ has affected the powder bed will inform as to how much of the powder remains in a usable state. Other methods used to evaluate powder caking, such as shear cells, penetrometers and uniaxial tests, are not able to quantify this phenomenon. Evaluating the energy gradient with respect to bed height, as the blade traverses the powder, the patented test protocol of the FT4, allows for an accurate measurement of both the strength and depth of the crust.

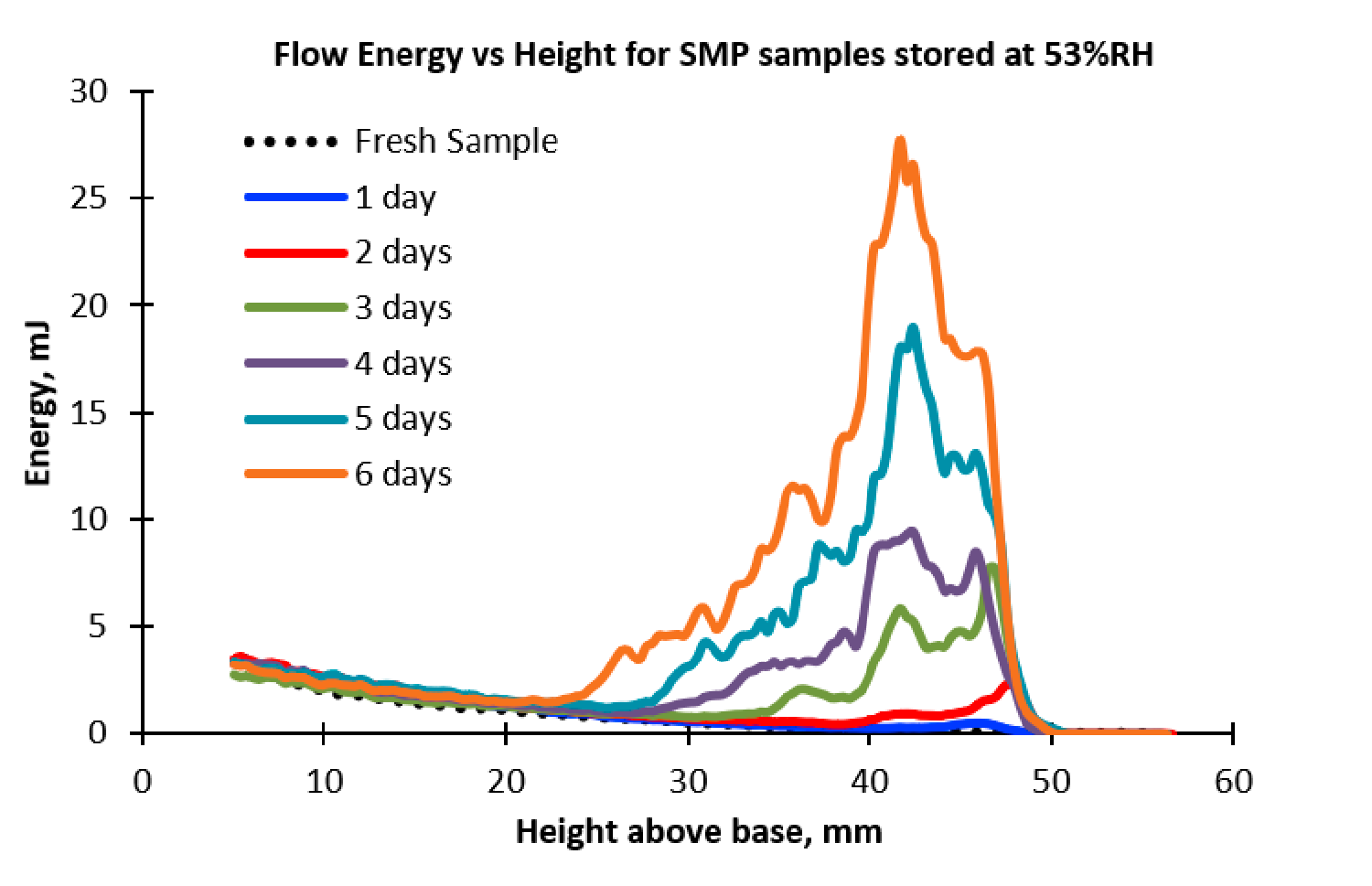

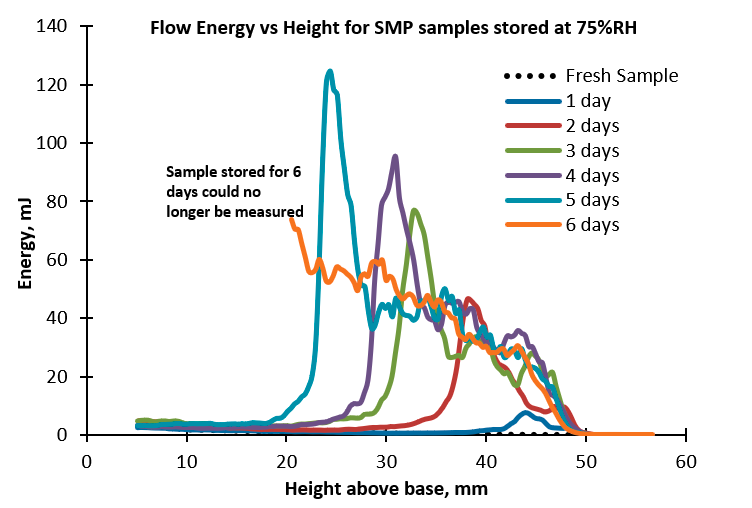

Samples of skimmed milk powder (SMP) were stored at 53% and 75% RH for up to six days, with one sample tested using the FT4 each day to evaluate the extent and location of consolidation within the bed.

In the samples stored at 53% RH, a clear trend was observed, where a solid crust formed at the powder-air interface and gained structural integrity and depth as storage time increased. Further into the bed, however, minimal consolidation was observed, suggesting that the formation of a relatively non-porous crust had minimised moisture migration in the lower part of powder bed.

When samples of the same powder were stored at higher humidity (75% RH), a different trend was observed. Once again, a solid crust formed at the powder-air interface, but this time, the area of highest consolidation progresses down through the bed as a function of storage time, leaving behind an area of moderate consolidation above an ‘active’ area of very high consolidation, representing the depth to which the moisture had penetrated the sample. As with the test at 53% RH, below the level of the crust, the powder remained unconsolidated, the crust having protected it from the effects of the humid environment.

This level of humidity was sufficient to penetrate to the bottom of the vessel over the course of the investigation, as evinced by the test on the sample after six days’ storage, which had solidified throughout the bulk and for which the flow energy could not be measured.

This difference in performance, dependant on the relative humidity under which the powder was stored, demonstrates that not only does humidity affect the extent to which caking can take place, but also the strength and depth of the resulting crust, and the rate of moisture migration through the powder bulk.

Temperature-Enhanced Caking

At elevated temperatures, the molecular mobility/viscoelasticity of materials is enhanced, reducing the particles’ hardness, and causing the material to undergo greater plastic deformation. This increases the contact area between particles and therefore the number of cohesive interactions, including surface chemical interactions, which promote caking within the powder bed. Being able to quantify the extent of these effects under elevated temperatures and consolidating loads, and correlating them with other powder properties (such as glass-transition temperature in the case of polymers, particle size or surface morphology), allows for a more in-depth understanding of the interactions between the powder and the storage conditions, and might help make the case for temperature controlled storage, or inform about powders stored and processed in warmer climates.

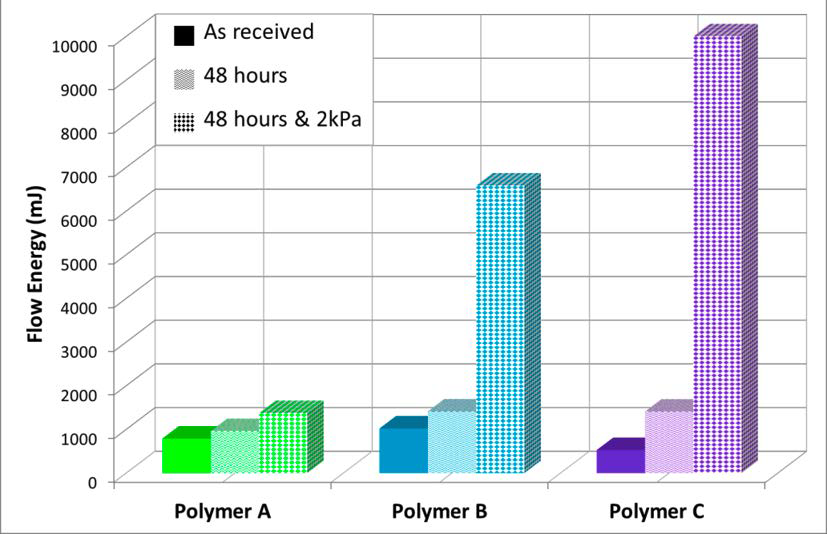

Identical samples of three different polymer powders were stored for 48 hours at 40°C, with and without an additionally applied normal load of 2 kPa to simulate storage in a small silo/bin. The samples were tested using the FT4 to evaluate the effect of the increased temperature, and the combination of temperature and moderate consolidation, on the caking properties.

The increase in Flow Energy between the fresh and stored samples indicates that the all three materials are sensitive to caking as a consequence of extended storage and elevated temperature. However, all three samples showed relatively comparable changes in Flow Energy when stored in an unconsolidated state. By contrast, Polymers B and C exhibited significant increases in Flow Energy as a result of storage under consolidation, likely due to a greater degree of plastic deformation imposed by the combination of elevated temperature and consolidating stress. In contrast, Polymer A presented a smaller increase in Flow Energy.

This illustrates that the conditions of the storage will have a significant effect on the resulting storage behaviour. Polymers B and C may not be subject to significant changes in flowability when stored in small quantities at elevated temperatures, but when stored in silos or bags under significant consolidating load, their flowability will change dramatically when compared with Polymer A.

Other Examples of Caking

When powders are blended together, chemical reactions can take place between the different components, resulting in the formation of stable chemical bonds that cause the powder bulk to agglomerate. Being able to chart the progress of this type of caking as a function of time enables engineers to optimise storage times and quantities to avoid problems during processing.

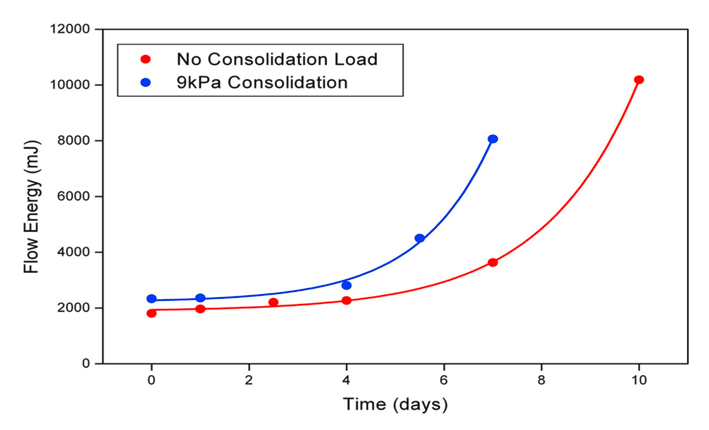

Identical samples of a three-component powder blend, known to chemically interact when mixed, were stored for up to ten days under ambient conditions, with and without an additionally applied normal load of 9 kPa to simulate storage in a silo/bin. One sample from each condition was tested with the FT4 each day to evaluate the increase in Flow Energy as a result of the storage.

In both sets of conditions, little or no increase in the Flow Energy observed for the first four days due to the slow rate of reaction between the components. After this point, however, the reaction rate increases and the mixture starts to cake. As the reaction progresses, the Flow Energy increases rapidly as the chemical interactions at the particles’ surfaces increase, and the mixture cakes.

During the initial period, the powder under the consolidated condition is marginally more caked than the non-consolidated sample, likely a function of reduced inter-particulate distances and as a result increased van der Waals interactions. After four days, when chemical reactions start to influence the Flow Energy significantly, the consolidated test group exhibits a much sharper increases in Flow Energy compared with the nonconsolidated sample, a further indicator that the caking reaction is enhanced by closer packing of the particles.

The results here demonstrate the need for a close understanding of the effects of the chemical interactions within the bulk of a powder.

Conclusion

Over time, the physicochemical nature of some powders subjected to humidity, temperature or stress can result in the development of a caked structure. This can occur through a number of mechanisms which are clearly not limited to any one of these external factors, and can have a significant impact on the flow properties and hence processing behaviour and final product quality. In most instances, these external factors result in reduced flowability, but this is not always the case, and under certain circumstances, combinations of factors can contribute to a powder becoming easier to move than its fresh counterpart. This illustrates how powder flowability is not an inherent material property, but is instead dependent upon the conditions and equipment under which the powder is processed. Successful processing demands that the powder and the process are well-matched, and it is not uncommon for the same powder to perform well in one process but poorly in another.

Regardless of the mechanism, the FT4 is a powerful tool that can effectively quantify a powder’s propensity to cake with respect to its flow properties, and this, in turn, can assist with understanding and ultimately adapting both the powder formulation and processing environment to limit caking and retain optimal processability.

References

[1] Freeman R., Measuring the flow properties of consolidated, conditioned and aerated powders – A comparative study using a powder rheometer and a rotational shear cell. Powder Technology, 25-33, 174, 1-2, 2007

[2] Katrina Brockbank, Brian Armstrong, Jamie Clayton, Measurement and quantification of caking in excipients and food productswith emphasis on the non-homogeneous interaction with ambient moisture. Particuology, 2020 – https://doi.org/10.1016/j.partic.2020.10.012