It provides fast, highly accurate, and reproducible results while maintaining the integrity of the sample.

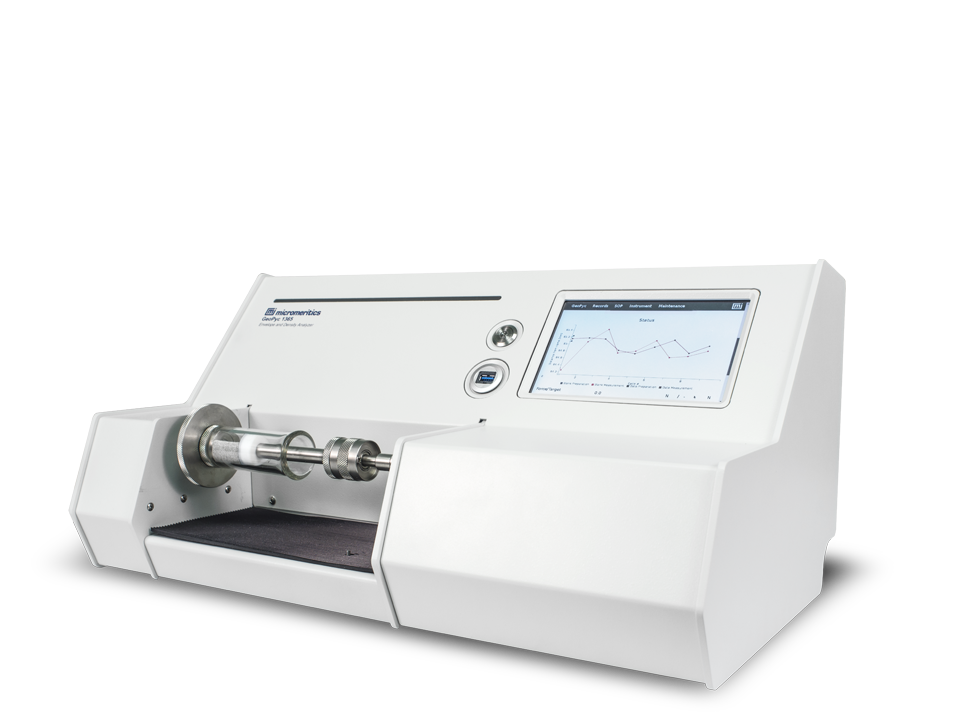

The GeoPyc is an innovative bench-top instrument designed for precise and efficient determination of the envelope volume and density of solid objects without the use of hazardous materials. By employing DryFlo, a non-invasive solid medium, the GeoPyc delivers rapid, reliable, and consistent results while preserving the integrity of the sample. Additionally, it offers an optional Trans-Axial Pressure (T.A.P.) analysis for comprehensive evaluation of the compressed bulk density of powders. When combined with skeletal density measurements, the GeoPyc can also provide detailed information on the pore volume and porosity of formed pieces.

The GeoPyc automatically determines the volume and density of a solid object by displacement of Dry Flo, a solid medium. The medium is a narrow distribution of small, rigid spheres that have a high degree of flow ability and achieve close packing around the object under investigation. The particles are sufficiently small that during consolidation they conform closely to the surface of the object, yet do not invade pore space.

Repeatability and reproducibility are achieved by a controlled method of compaction. The sample cell in which the dry medium is placed is a precision cylinder. A plunger compresses the powder as the cell vibrates; the force of compression is selectable and, therefore repeatable from test to test. A preliminary compaction with only the displacement medium in the cell establishes a zero-volume baseline.

The sample is then placed in the cylinder with the dry medium and the compaction process is repeated. The difference in the distance ht the piston penetrates the cylinder during the test and the distance h0 it penetrates during the baseline procedure (h=h0– ht ) is used to calculate the displacement volume of the medium using the formula for the volume of a cylinder of height h, V =π r2h

The GeoPyc is operated from an intelligent touch screen. Data acquisition and reporting are fully automated for convenient incorporation in LIMS or other data concentrating systems. A variety of sample chambers is available to accommodate a wide range of sample sizes. After the analysis, a light shaking or dusting completely removes the Dry Flo so the samples can be reused or retested.

The GeoPyc has multiple operating modes including full blank, computed blank, and reference solid calibration with variance, which allows you to optimize speed and accuracy for your individual needs. During analysis, indications of progress and preliminary results make it possible to track what is occurring.

The GeoPyc has multiple operational modes that are accessed through the instruments smart touch screen. Operating modes including full blank, computed blank, and reference solid calibration with variance, which allows you to optimize speed and accuracy for your specific application. During analysis, indications of progress and preliminary results make it possible to track what is occurring. Sample specific information can be entered into the analysis reports. Available Reports: Envelope Density, Volume Calibration, Blank Report, Force Calibration, Instrument Log

The GeoPyc T.A.P. density option obtains precise results comparable to conventional tap density analyzers, only it does it faster, quieter, and with a higher degree of reproducibility.

When equipped with the T.A.P. Density option, the GeoPyc measures the packing volume and calculates the bulk density of granular and powdered samples, including pharmaceutical and electrochemical materials, under a wide range of compaction conditions.

To determine T.A.P. density, the sample chamber is rotated and agitated while a precise specified force is applied to the sample. A force transducer measures the consolidation force in Newtons and the distance over which the consolidation piston and plunger travel is measured in steps. The user specifies the force applied and the number of consolidations per analysis. The GeoPyc averages the measurements from each consolidation and automatically calculates volume and density, and reports the results in cm3 and g/cm3

| When sample volume is at least 25% of sample holder volume: Typically ± 1.1% |

| 12.7-mm (0.50 in.) ID | Sample volumes between 0.3 cm³ and 0.8 cm³ |

| 19.1-mm (0.75 in.) ID | Sample volumes between 0.8 cm³ and 2.4 cm³ |

| 25.4-mm (1.00 in.) ID | Sample volumes between 2.4 cm³ and 5.3 cm³ |

| 38.1-mm (1.50 in.) ID | .Sample volumes between 5.3 cm³ and 13 cm³ |

| 50.8-mm (2.00 in.) ID | Sample volumes between 13 cm³ and 25 cm³ |

| Height | 11 in |

| Width | 22 in |

| Depth | 15 in |

| Weight | 42 lbs |

| Voltage | 85 to 265 VAC |

| Frequency | 47 to 63 Hz |

| Electrical Power | 95 VA |

| Temperature | 15 °C to 35 °C |

| Humidity | 20% to 80% non-condensing |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Request a quote or talk to an expert for more information

to stay connected to product news, software updates, and the latest scientific resources

Copyright © 2025 Micromeritics Instrument Corporation