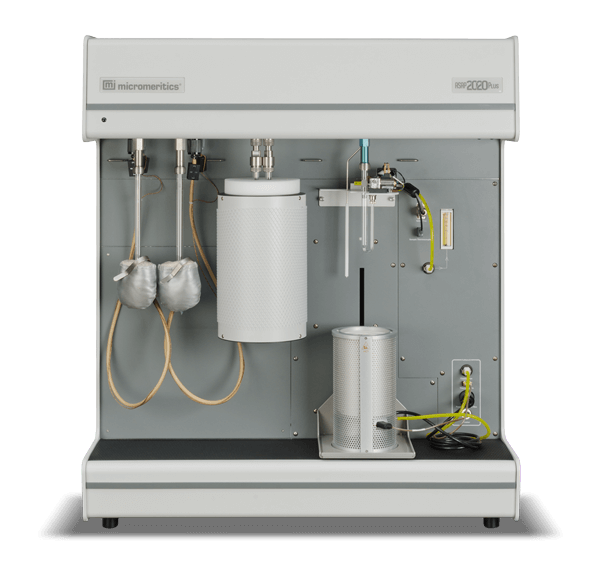

The ASAP 2020 Plus is a high-performance adsorption analyzer for measuring surface area, pore size, and pore volume of powders and porous materials. Standard methods or user customized protocols can be used to characterize adsorbents, catalysts, zeolites, MOFs, APIs, excipients, and a wide variety of porous and non-porous materials. The ASAP 2020 Plus is ideally suited for gas adsorption analysis of microporous (0.35 to 2nm) and mesoporous (2 to 50nm) materials and delivers superior accuracy, resolution and data reduction. A vapor sorption option can be added to the ASAP 2020 Plus to extend the analysis range of the ASAP 2020 Plus physisorption.

A chemisorption option extends the application range of the ASAP 2020 plus to both physical and chemical adsorption for characterizing the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

Proven Isothermal Jacket Cold Zone Control provides accurate, reproducible temperature maintenance

The ASAP 2020 Plus can be configured to your specific needs with the option of upgrading at a later date as your analytical requirements change, maximizing the utility of this instrument and your investment.

Choose from low surface area, to heated vapor, to micropore capability. Add a cryostat, an external detector, or configure the unit for enhanced chemical resistance when working with aggressive vapors. The ASAP 2020 Plus permits one instrument to accommodate almost any surface characterization need in your lab.

A chemisorption option extends the application range of the ASAP 2020 plus to both physical and chemical adsorption for characterizing the texture and active surface of catalysts, catalyst supports, sensors and a variety of other materials.

Isothermal jackets are guaranteed for the life of the instrument and ensure a constant thermal profile along the full length of both the sample and saturation pressure (Po) tubes.

Equipped with a 10-mmHg transducer and a high vacuum pump. This system provides the low-pressure capability and pressure-measurement resolution required for low surface area analyses using krypton as the adsorptive.

The stainless-steel manifold is available with chemically resistant Kalrez® seals to support analyses using aggressive gases or vapors as the adsorptive.

Includes a 0.1-mmHg transducer and a high vacuum pump. This system delivers accurate porosity data on pores between 0.35 and 3 nanometers and provides a comprehensive selection of micropore reports.

Cold trap option available for your specific application.

Includes optional vapor accessories.

ASAP 2020 Software Features The easy-to-use ASAP 2020 software utilizes a Windows® interface that includes Wizards and applications to help plan, launch, and control the analysis. You can collect, organize, archive and reduce raw data, and store standardized sample information and analysis conditions for easy access during later applications.

Finished reports may be generated to screen, paper, or data transfer channels. Features include cut-and-paste graphics, scalable-and-editable graphs, and customizable reports. Additional capabilities include:

The ASAP 2020 includes powerful data reduction software to provide a variety of easy-to-interpret report options. This allows tremendous flexibility in the selection of analysis constants to best fit your specific application. All ASAP models have the capability to collect data over a prescribed segment of the pressure range, or to perform adsorption and desorption analyses over the entire pressure range, providing extensive surface area and porosity information.

Surface area and porosity play major roles in the purification, processing, blending,...

+Surface area and porosity affect the curing and bonding of greenware and...

+Knowledge of surface area, total pore volume, and pore size distribution is...

+Surface area and porosity must be optimized within narrow ranges to accomplish...

+The wear lifetime, traction, and performance of tires are related to the...

+Fuel cell electrodes require high surface area with controlled porosity to produce...

+The active surface area and pore structure of catalysts influence production rates....

+The surface area of a pigment or filler influences the gloss, texture,...

+The burn rate of propellants is a function of surface area too...

+Controlling the porosity of artificial bone allows it to imitate real bone...

+By selecting high surface area material with carefully designed pore networks, manufacturers...

+Surface area is often used by cosmetic manufacturers as a predictor of...

+Surface area and porosity of heat shields and insulating materials affect weight...

+Porosity is important in groundwater hydrology and petroleum exploration because it relates...

+Nanotube surface area and microporosity are used to predict the capacity of...

+| Physisorption | Chemisorption |

| Analysis Range | 1.3 x 10-9 to 1.0 P/P0 | 1 x 10-6 to 900 torr |

| Roughing Pump | 4 stage diaphragm | 4 stage diaphragm |

| Minimum Measurable Surface Area | Standard 0.01 m2/g 0.01 m2/g Krypton 0.0005 m2/g 0.0005 m2/g |

- |

| Physisorption | Chemisorption |

| Adsorptive Gas Inlets | 6 | 12 standard; optional up to 16 |

| Vapor Sorption Option | Included, optional heated vapor source | Included, optional heated vapor source |

| Furnace | N/A | Ambient to 1100°C Programmable from 0.1 to 50 °C/min |

| Degas | 2 | 2 |

| Pressure Transducer System | 1000 torr 0.12% reading | 1000 torr 0.12% reading |

| Transducer Accuracy | 10 torr 0.12% reading 0.1 torr 0.15% reading |

10 torr 0.12% reading 0.1 torr 0.15% reading |

| Physisorption | Chemisorption |

| Cryogen Dewar | 3.2 L, unlimited holding time with refill during analysis | 3.2 L, unlimited holding time with refill during analysis |

| Cryogen Free Space Control | Isothermal Jacket | Isothermal Jacket |

| Physisorption | Chemisorption |

| Data Analysis for Texture and Active Area | BET Surface Area, t-Plot, BJH, Horvath-Kawazoe, Saito-Foley, Cheng-Yang, DFT, NLFT, and others | Metal dispersion, Metal surface area, Crystallite Size |

| Advanced Modeling | Heat of Adsorption, GAB, Sips, Toth, dissociative Langmuir, Redlich-Peterson, Virial Equation, AutoFit BET |

| Instrument Operation Dashboard | Dashboard permits real-time monitoring of critical parameters |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Request a quote or talk to an expert for more information