The mercury porosimetry analysis technique is based on the intrusion of mercury into a porous structure under stringently controlled pressures. Besides offering speed, accuracy, and a wide measurement range, mercury porosimetry permits you to calculate numerous sample properties such as pore size distributions, total pore volume, total pore surface area, median pore diameter and sample densities (bulk and skeletal).

The AutoPore V Series Mercury Porosimeters can determine a broader pore size distribution more quickly and accurately than other methods. This instrument also features enhanced safety features and offers new data reduction and reporting choices that provide more information about pore geometry and the fluid transport characteristics of your material.

Triple Fail Safe - 2

Interlock on Locking Cap

Mercury Collection Trays

Improved Mercury Funnel Design

Mercury Vapor Detection Device

MicroActive software greatly improves the functionality, convenience, diagnostics, and data interpretation that establish the new standard for high-performance results in mercury porosimetry.

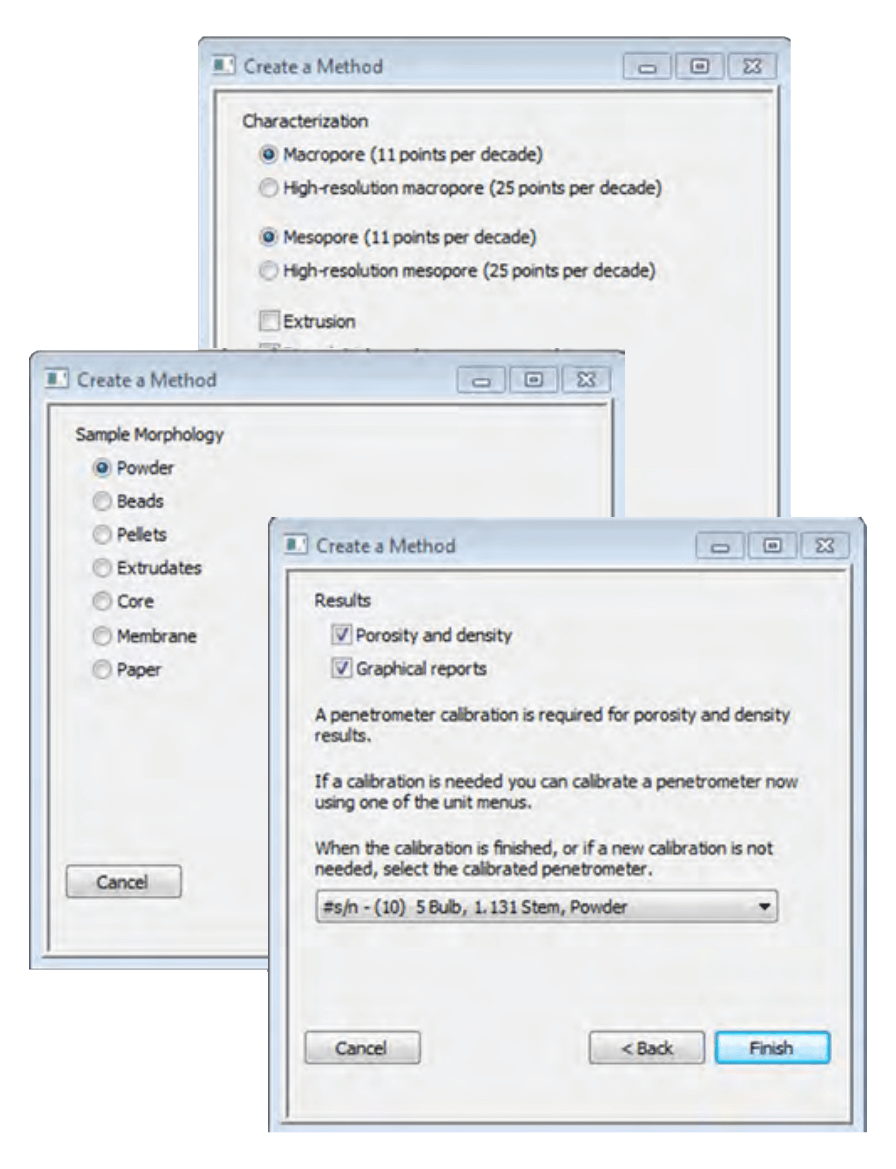

Build a method through an interactive step-by-step script. Eases method creation and new user introduction to the operation of the AutoPore V.

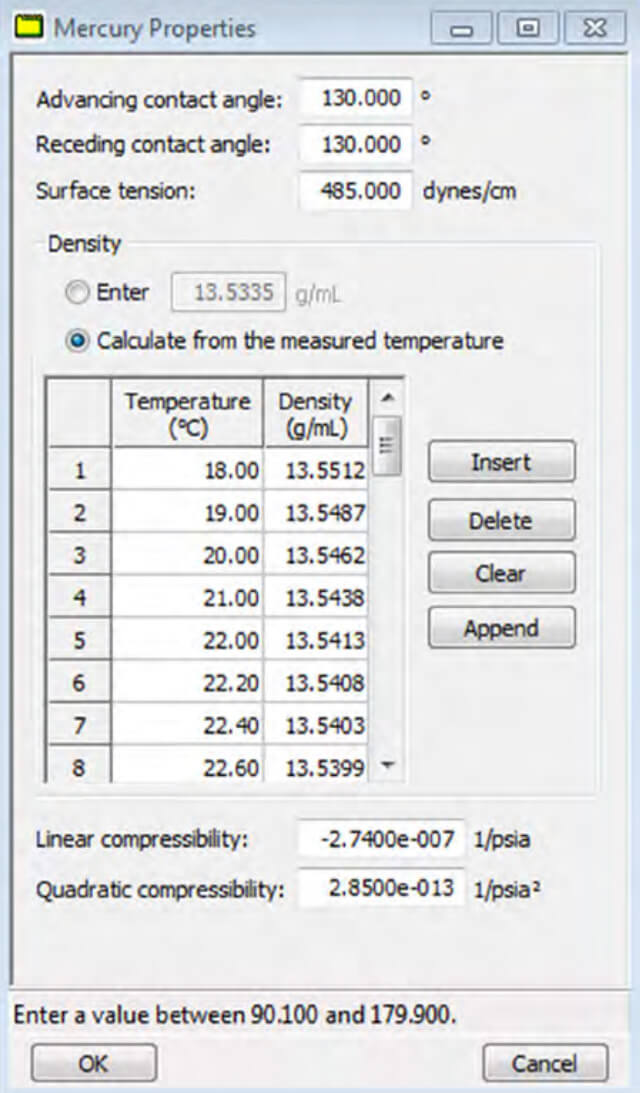

Unlike competitive systems that use mercury density at ambient temperature only, the AutoPore V automatically measures the actual mercury temperature for accurate density calculations under operation conditions.

You can quickly create custom advanced reports to meet your specific needs using Python scripting. New report options permit automatic report conversion to PDF or spreadsheet formats.

Allows analysis parameters (stem volume, maximum head pressure, pen constant) to be changed or corrected post analysis, eliminating re-running samples due to error.

Receive information on the distribution of pore shape. The method yields a three-dimensional array of cavity size and throat size vs. volume.

Real-time monitoring of critical system components for preventative maintenance and trouble shooting

Warnings are supplied automatically when suspect data are collected

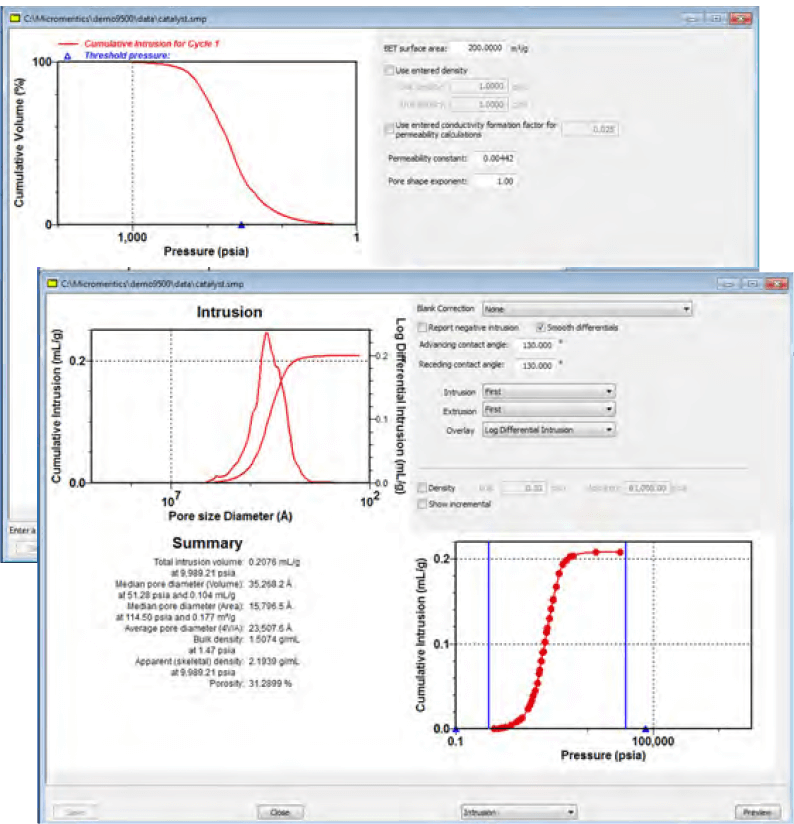

Pore volume, pore area, and pore size plots are available as well as the ability to calculate total intrusion volume, total pore (surface) area, median pore diameters, average pore diameters, bulk or envelope density, and apparent (skeletal) density

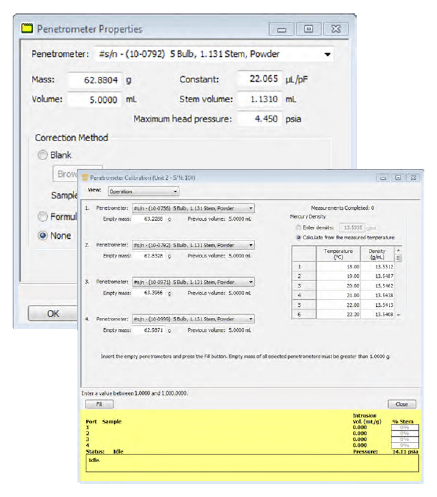

Simplifies penetrometer calibration through automated calculations either volumetrically or gravimetrically

MicroActive for Autopore V provides the ability to overlay up to 20 runs. Included is the option to import pore size distributions from gas adsorption isotherms to provide analysis data in the micro to macropore range in a single report

| Model# | Size | Stem Volume | Medium | Typical Use |

|---|---|---|---|---|

| 01 | 15 cc | 0.392 | Solid | refractories, low-porosity solid rocks/cores, low porosity solid polymers |

| 02 | 15 cc | 0.392 | Powder | low-porosity powders, gravel, irregular rock shapes |

| 03 | 15 cc | 1.131 | Solid | medium-porosity rocks/cores, solid materials |

| 04 | 15 cc | 1.131 | Powder | medium-porosity rocks, solid materials, fumed silica |

| 07 | 5 cc | 0.392 | Solid | paper, flexible polymer/membrane sheets, pharma tablets |

| 08 | 5 cc | 0.392 | Powder | silicates, catalysts, powders (general use), pharma powders |

| 09 | 5 cc | 1.131 | Solid | medium/high-porosity sheet-form materials (paper, polymer, etc.), pharma tablets |

| 10 | 5 cc | 1.131 | Powder | silica-alumina, silicates, zeolites, catalysts, powders (general use), pharma powders |

| 14 | 3 cc | 0.412 | Powder | powders (general use), materials with low quantity available |

| 24 | 15 cc | 3.263 | Solid | high-porosity rock/cores, low-density/high-porosity foams |

| 25 | 15 cc | 4.185 | Solid | high-porosity material with large volume |

Porosity and surface area play major roles in the purification, processing, blending,...

+Pore area and porosity affect the curing and bonding of greenware and...

+Knowledge of pore area, total pore volume, and pore size distribution is...

+The active surface area and pore structure of catalysts influence production rates....

+Surface area and porosity of heat shields and insulating materials affect weight...

+Fuel cell electrodes require controlled porosity with high surface area to produce...

+Porosity is important in groundwater hydrology and petroleum exploration because it relates...

+Pore size, pore volume, pore shape, and pore tortuosity are of interest...

+Diffusion, permeability, and capillary flow play important roles in the degradation processes...

+The porosity of print media coating is important in offset printing where...

+Surface area and porosity of heat shields and insulating materials affect weight...

+| Low Pressure (all models) | High Pressure |

| Measurement | 0.2 to 50 psia (345 kPa) | 9600/9605: From atmospheric pressure to 33,000 psia 9610/9620: From atmospheric pressure to 60,000 psia |

| Pore Diameter Range | 1100* to 3.6 µm (*calculated with initial filling pressure of 0.2 psia) | 9600/9605: 6 to 0.005 µm 9610/9620: 6 to 0.003 µm |

| Resolution | 0.00025 psia | 9600/9605: 0.165 psia from 3,300 psia to 33,000 psia 9610/9620: 0.03 psia from atmospheric pressure to 60,000 psia |

| Transducer Accuracy (transducer manufacturer’s specifications) | +/- 1% of full scale | +/-0.1% of full scale |

| Transducer Hysteresis | - | 0.05% of full scale |

| Servo Control Precision | 1% of target, min 0.05 psia, no overshoot | 0.5% of target, min 5 psia, no overshoot |

| Intrusion Resolution | Better than 0.1 all |

| Intrusion Accuracy | +/- 1% of maximum penetrometer stem volume |

| Gas | Nitrogen or other clean, dry gas at 50 psig (345 kPa) |

| Low Pressure (all models) | High Pressure |

| Voltage | 100/120/220/240 VAC ± 10% |

| Frequency | 50 or 60 Hz |

| Power | 500 VA maximum |

| Low Pressure (all models) | High Pressure |

| Height | 143 cm (56.25 in.) |

| Width | 54.3 cm (21.38 in.) |

| Depth | 78 cm (30.75 in.) |

| Weight | 250 kg (500 lb) |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Request a quote or talk to an expert for more information