The Vapor Generator option for the AutoChem provides a means to quantitatively inject pulsed dose amounts of vapor onto a solid sample. Vapors of most interest are actually gases below their critical temperature; hence, they are condensable. Design features and operation of the AutoChem’s vapor generator are described in Product Bulletin 83.

Reagent grade 2-propanol (boiling point 97 °C) was used to demonstrate the accuracy and reproducibility of the AutoChem and vapor generator for dosing vapor at a specific pressure. A series of three experiments was performed in which 15 repeated pulses of 2-propanol were made from the vapor generator with an inert helium carrier gas. The three different vapor pressures were obtained using reflux zone temperatures of 60, 70, and 80 °C.

The conditions of the experiments were:

- An empty sample tube; the furnace was maintained at 120 °C to prevent condensation of the alcohol in the tube.

- All compartments of the AutoChem were heated to 130 °C.

- Helium was used as the loop gas and the carrier/reference gas.

- The boil-zone temperature of the vapor generator was held 20 °C higher than the reflux zone.

- A nominal 0.5-cc injection loop was employed. The exact volume of the loop at 130 °C was 0.3363 cc.

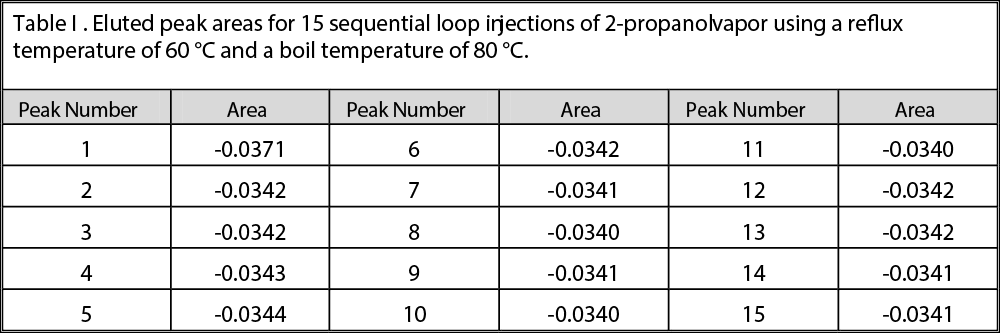

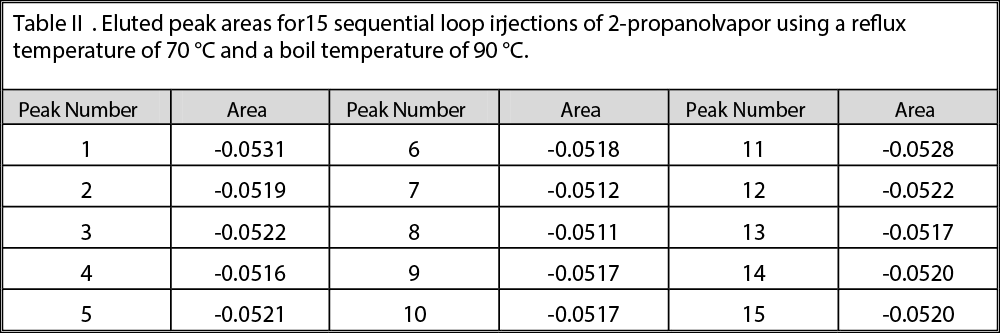

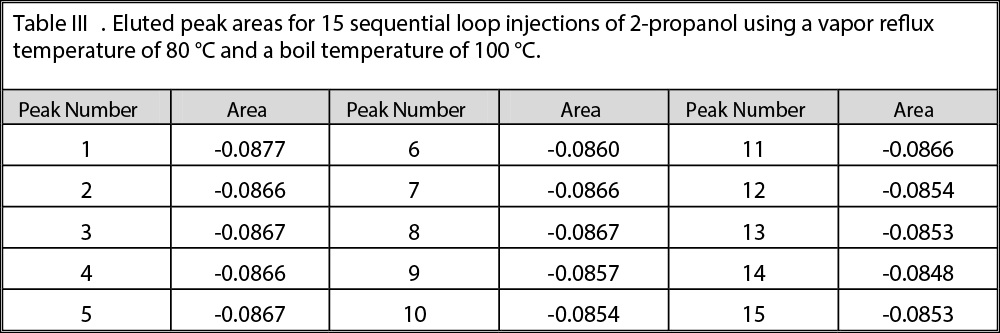

Tables I, II and III show the integrated peak areas for all 15 injections at the three respective vapor reflux temperatures of 60, 70, and 80 °C.

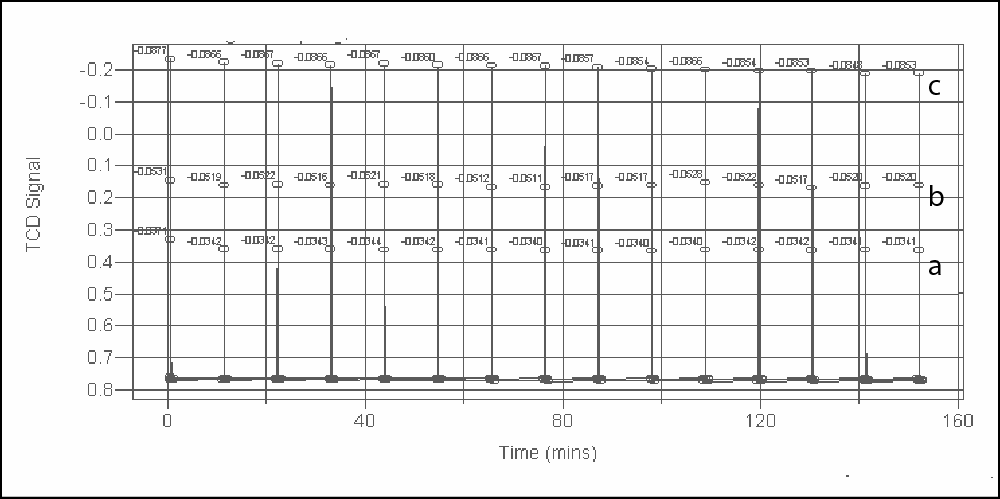

The three TCD traces are shown overlaid in Figure 1.

Figure 1.The time vs. signal outputs from the TCD detector for 15 sequential injections of 2-propanol vapor at three different reflux temperatures; (a) 60 °C, (b) 70 °C, and (c) 80 °C.

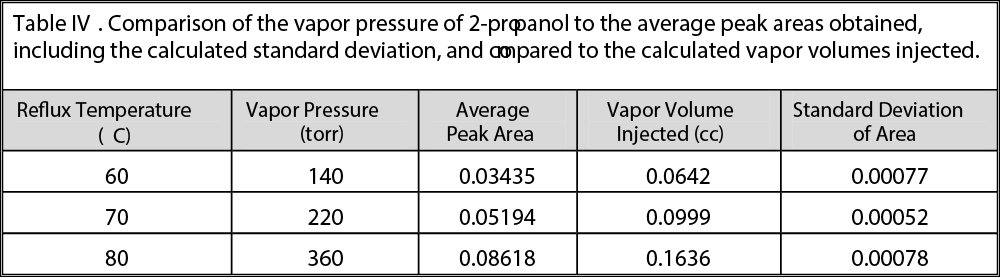

The summary data are given in Table IV. The standard deviations for the integrated peak areas for the three different temperature series are all well below 1%. The active volume injected compares quite well with that expected from the known vapor pressure of the 2-propanol.

Accuracy of Vapor Dosing with the AutoChem