Abstract

Measuring asphalt density per ASTM Test Method D70-09 requires the use of a glass pycnometer and very tedious analysis conditions. Using this ASTM method as a guide, the density of asphalt is measured using an AccuPyc II TEC and 3.3-cc disposable aluminum cups. The density results of four different asphalt samples using the AccuPyc are compared to results obtained by a third party using the ASTM glass pycnometer method. Results from the two methods ranged from a 0.003% to 0.026% difference.

Introduction

Asphalt density is used in the calculation to determine the quality and amount of asphalt needed to pave roads. The quality and uniformity of the mixture determines whether a road will be paved evenly and if the thickness of the pavement at different points is also uniform.

The density of asphalt is currently determined by using a glass pycnometer as described by ASTM Test Method D70-09. The pycnometer must be cleaned thoroughly and have no defects or weaknesses. Using an analytical balance and a water bath, the density of water is first obtained using the pycnometer. Then the asphalt sample is heated until it is viscous enough to pour. The glass pycnometer is filled about three-fourths full and weighed, then filled to full with water and weighed. The final calculation described in the ASTM method allows the analyst to determine the density of the asphalt at 25 °C. If anything happens to compromise the pycnometer, such as breakage, the entire procedure must be repeated using a new pycnometer.

The goal of this application note is to obtain the same density values for four (4) asphalt samples, Sample A, Sample B, Sample C, and Sample D, using the AccuPyc II TEC and disposable sample cups, a much cleaner and easier method. For scientific quality, a third party lab withheld the actual density values collected using the ASTM pycnometer method until the project was completed.

Experimental

Materials

- AccuPyc II TEC with 3.3-cc disposable aluminum sample cups and nitrogen gas

- Analytical balance

- Laboratory oven

- Disposable plastic pipettes

Procedure

For each sample, twelve (12) 3.3-cc disposable aluminum cups are labeled. The first eleven cups are labeled sequentially from 1 to 11 and the 12th cup is labeled “cal cup.” The “cal cup” is the cup that will be used to calibrate the AccuPyc. Its mass and volume are used to correct for the volume of the other eleven sample cups used on the day of analysis and under the same conditions.

Once all twelve cups are labeled, they are placed in a preheated laboratory oven at not less than (NLT) 163 °C for NLT 30 minutes. This is the conditioning step. The cups are then removed from the oven and allowed to cool to room temperature and weighed, including the “cal cup.” Cups 1 thru 11 are then placed back into the oven until the asphalt is ready to be sampled. The “cal cup” is taken to the AccuPyc and used for the calibration.

The bulk container of sample asphalt is placed in the oven at NLT 163 °C for about an hour or until the asphalt is soft enough to be drawn into a disposable plastic pipette. Once the asphalt is ready, small aliquots are placed into cups 1 thru 11 using the disposable pipettes. Each cup is filled about half way to three-fourths full, being careful not to get asphalt on the side of the cup. Once the cups are filled, the cups with the asphalt aliquots are placed back in the oven for about an hour to remove any air pockets that may have formed. The cups are then removed from the oven, allowed to cool to room temperature, and a final weight is taken.

The AccuPyc is set up with the following conditions:

- Gas: Nitrogen

- Number of Purges: 2

- Purge Fill Pressure: 19.500

- Number of Cycles: 99

- Cycle Fill Pressure: 19.500

- Equilibration Rate: 0.0050

- Peltier Temperature Setting: 25.0°C

The “Cal Cup” is then placed into the AccuPyc and the standard procedure used to calibrate the volume is used. A 2.5-cm steel ball standard with a volume of 1.7671 cc is used as the calibration standard. Once the calibration is complete, a sample file labeled “check standard” is created using the same parameters to be used on the asphalt aliquots. The steel ball is then analyzed as a sample to verify the volume measured. Each asphalt aliquot is analyzed and the data files created are labeled with the sample identification number and the cup number.

Once all the data are collected, the volume of each aliquot cup is corrected by taking the difference in the weights between the empty aliquot cup and the “cal cup,” then dividing by 2.7 g/cc (density of aluminum). The sample weight is then divided by the corrected cup volume to calculate the density of the sample.

Results

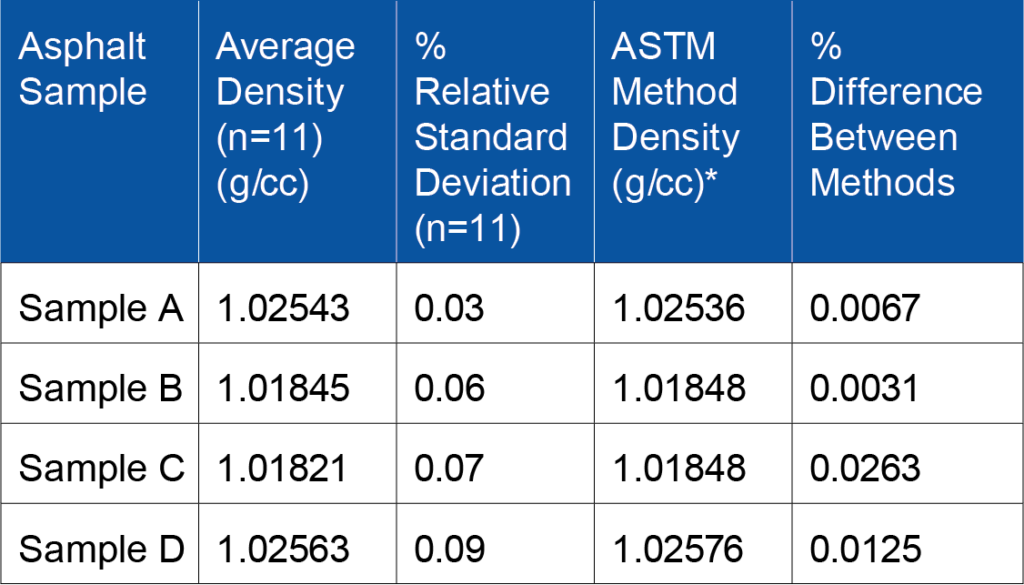

The results for each asphalt sample submitted are displayed in the following table.

Conclusion

Accurately measuring the density of asphalt is crucial to the quality of paved roadways. It is possible to obtain accurate asphalt density values using an AccuPyc II TEC and 3.3- cc disposable aluminum cups. The average results of 11 test samples agree with results collected by a third-party laboratory using the glass pycnometer method described in ASTM Test Method D70-09 on the same batch of asphalt.