Volume, density, and porosity are interrelated parameters widely recognized as important for the control of drug product manufacture. Tableted medicines need to be a consistent size and shape for efficient packaging and patient acceptability.

Envelope density can be a useful check of tablet consistency, since it may be influenced by the extent of compaction, while the skeletal density of a granulated tableting blend may be controlled to achieve acceptable flowability or compressibility in the press.

Porosity impacts how easily a solvent penetrates the solid matrix of the tablet and as a result may be designated as a critical quality attribute (CQA) for tablets (or granulated products). The rate of solvent penetration affects disintegration and dissolution, these control bioavailability and thus clinical efficacy. So, if two tablets are made with the same mass of active pharmaceutical ingredient (API), but one is more porous than the other, then the more porous version would be expected to dissolve faster, leading to faster API release. While variability in porosity, from tablet to tablet in a batch, is unacceptable. Porosity may be tailored to achieve differing dissolution rates depending on the clinical need. Tablets for rapid dissolution often have high porosity for exactly this reason. These parameters are discussed in the “Physical Properties Primer” below.

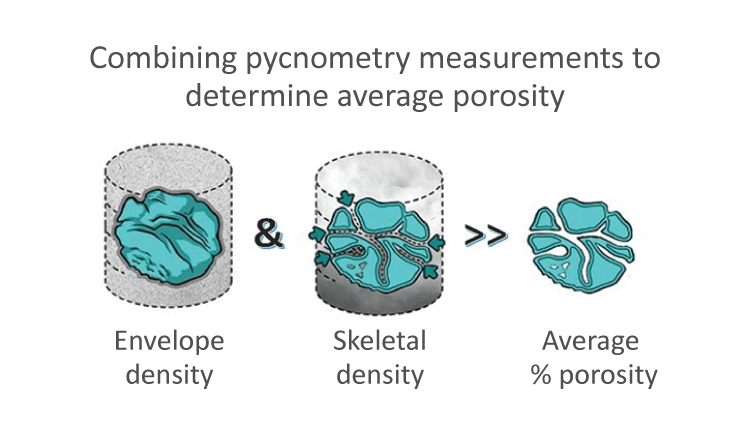

The Micromeritics® AccuPyc® gas pycnometer and Micromeritics® GeoPyc® envelope density analyzer measure skeletal and envelope volume, respectively. Density values can be calculated from these volumes and a supplied mass. Either system can generate a value for porosity, if supplied with the density measured by the other technique. These capabilities make the instruments a valuable combination for pharmaceutical applications, particularly for tablet and ribbon analysis. This note presents data for a range of tablets illustrating the data these systems generate, separately, and in combination.

The Equipment

The AccuPyc Gas Pycnometer

The AccuPyc has a fixed volume sample chamber which is connected to a gas supply via a fill valve (a). When the fill valve (a) is opened the increase in pressure is monitored with a pressure transducer (t). A second fixed volume chamber is connected to the first via the expansion valve (b). Gas can be vented from the system using the vent valve (c).

The system is calibrated using a traceable volume. This is one or more precisely manufactured steel spheres of certified volume. The calibration procedure accurately determines the volume of each chamber by reference to the sphere volume. The calibration is held by the system and therefore it is not necessary to calibrate before every experiment.

Once the system is calibrated, the sample can be loaded. A bayonet closure ensures a stable sample chamber volume. The sample chamber is then pressurized to a defined level with a dry inert gas (usually helium or nitrogen) through the fill valve (a). The pressure is automatically recorded once equilibrated and a stable reading is found on transducer (t). Opening the expansion valve (b) allows gas to flow into the expansion chamber, the pressure drops throughout the system, and is again recorded once the reading on transducer (t) has equilibrated. This process is repeated and averaged to give highly reproducible results.

Using the ideal gas law, the volume occupied by the sample can be calculated from the volume of the chambers and measured pressure. The volume measured is the skeletal volume of the sample, since gas penetrates all accessible pore space.

The GeoPyc Envelope Density Analyzer

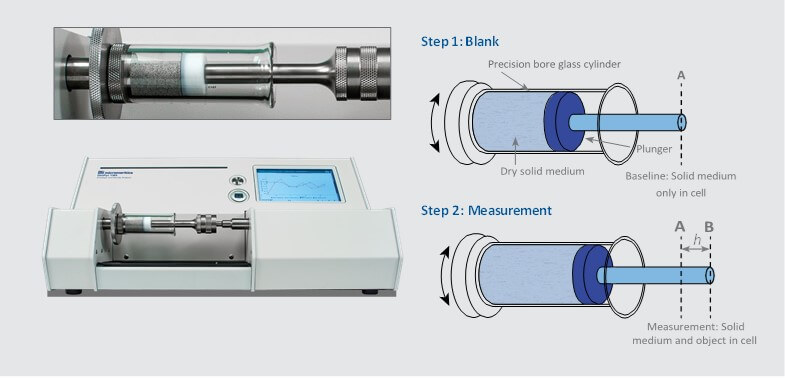

The GeoPyc has a precision cylinder of known diameter which is filled with a free-flowing quasi-fluid solid displacement media to conduct a measurement.

The cell is oscillated, to vibrate the media, which is simultaneously compressed to a defined consolidation force to establish the zero-volume baseline (position A, in Step 1: Blank). The sample is then added into the cylinder and the compaction process is repeated (position B, in Step 2: Measurement).

The volume of the sample is calculated from the difference in the distance that the piston travels to achieve an equivalent consolidatory force (h, the distance between positions A and B, in Step 2).

The displacement media conforms closely to the surface of the sample during the measurement but does not penetrate any of the internal porosity. This is in contrast, to the AccuPyc were the gas fills all available porosity. The resulting volume measured by the GeoPyc is therefore described as the envelope volume.

Experimental Details

A range of over-the-counter tableted medicines was tested using the AccuPyc and GeoPyc. Several of each tablet were tested to simulate the sampling that might be carried out within a manufacturing plant for process control.

All sample preparation and testing, including system calibrations, data collection for 14 sample sets and bookend tests was completed in around 6 hours. Full details of the experimental methods, instrument settings used, and data processing steps applied can be found in a separate white paper. Please contact us for more information.

Results and Data Analysis

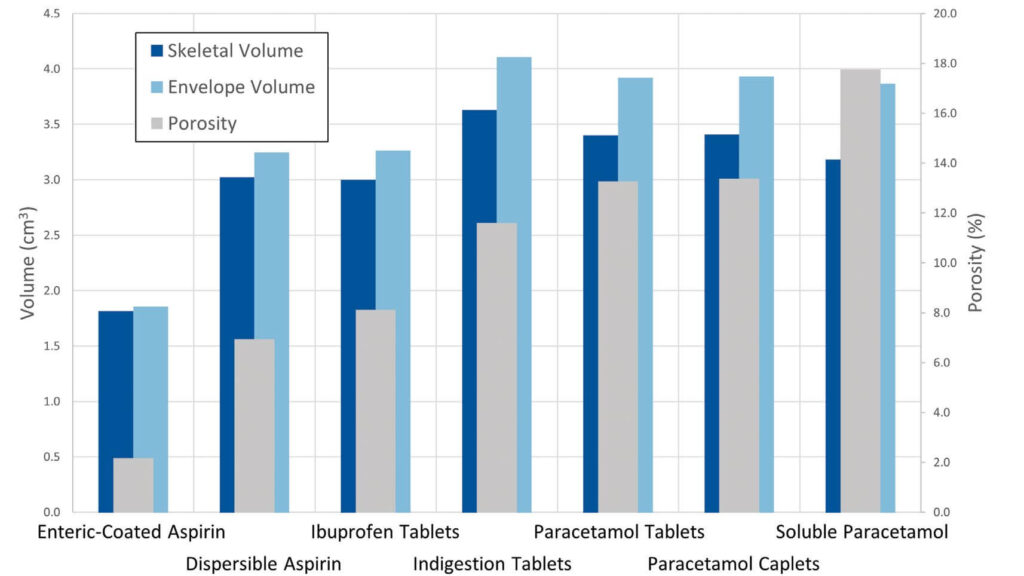

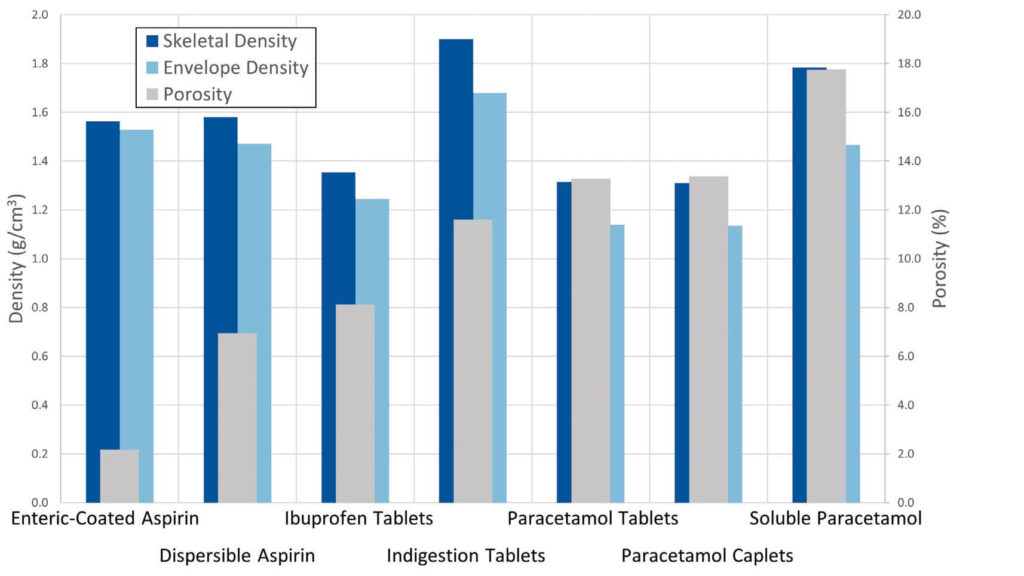

The following two plots show volume (upper) and density (lower) data for each of the samples. Porosity data are also included on both plots and the samples are arranged along the x-axis in order of increasing porosity (left to right) to elucidate correlations between the sets of data.

The data show that neither volume or density, skeletal or envelope, exactly track the porosity data. The patterns in the volume data are somewhat similar and could be weakly correlated, but both skeletal volume and envelope volume data show marked differences relative to the porosity data for certain tablets. The patterns in the density data are distinctly different from those in the porosity data, with no evidence of correlation between the two.

The results, therefore, illustrate that volume, density and porosity are distinct, independent attributes of the tablet. Each, therefore, provides a unique insight into the tablet quality that can be used to achieve effective control.

Conclusion

This simple study illustrates how the AccuPyc and GeoPyc can be used to efficiently measure a series of useful characteristics for tableted medicines. Volume, density, and porosity values can all be recorded to robustly and clearly differentiate products.

The results show that despite an element of interrelation between these parameters, they exhibit different trends. So, by making two rapid and simple laboratory, or at-line tests, it is possible to generate five discrete, independent parameters, all with potential application for process and product quality control.

Physical Properties Primer – Density, Volume and Porosity

Density

At first sight, density is a relatively straight forward term defined as mass divided by volume. On a lab scale, values are typically stated in g/cm3. However, there are multiple ways to define and quantify volume. Each gives rise to a different density parameter.

Volume

In the study described here, envelope and skeletal density were determined from measurements of:

– Envelope volume, which is the volume the sample occupies in space, including both the solid content of the sample and any pore space or voids within it

– Skeletal volume, which is the volume of actual solid that makes up the sample

Porosity

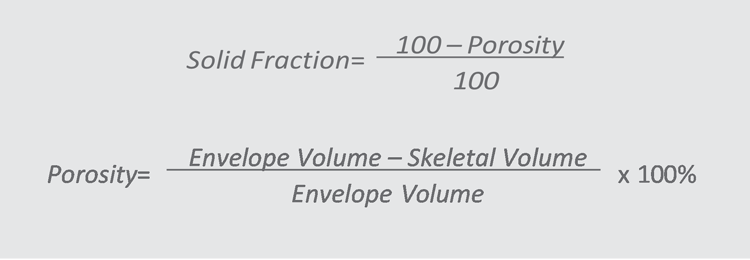

Porosity is a dimensionless value, normally quoted as a percentage. It quantifies how much of a sample is solid and how much is empty space. Porosity can be calculated using the equation below when working with volume values and is independent of mass. There is also a corresponding equation that can be used with density values. The solid fraction can also be calculated from a knowledge of porosity: