Pore size distribution is usually determined by gas adsorption techniques from the gas adsorption isotherm. For samples with 2 to 50-nm pore structure, BJH is the most commonly used method for calculating pore size distribution.

In order to get good results, sufficient isotherm sorption points are needed. However, the adsorbed volume at a certain relative pressure usually cannot be predicted before measurement, resulting in insufficient points for the BJH pore size distribution calculation.

If additional data points need to be collected between target pressures, a feature in Micromeritics software named Maximum Volume Increment can be used. When using this feature, if the maximum increment has been adsorbed since the last collected data point, then another point is equilibrated and collected.

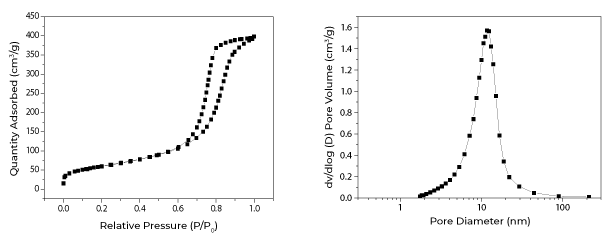

The Silica-Alumina sample illustrates how the Maximum Volume Increment feature works. In Figure 1, the isotherm shows only a few collected points in the relative pressure range of hysteresis. Therefore, there are fewer points in the BJH pore size distribution.

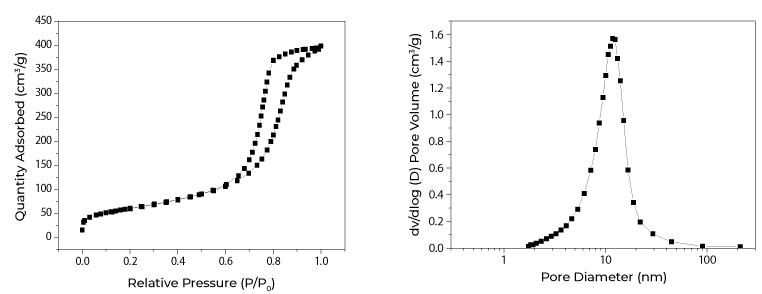

Contrast this result with the effect of using the Maximum Volume Increment feature shown in Figure 2. In this experiment, maximum volume increment is 15 cm3/g. The isotherm seen in the resulting data plot has more points in the relative pressure range of hysteresis. The greater number of data points automatically collected by the Maximum Volume Increment feature provides increased isotherm definition leading to significantly better resolution of the BJH pore size distribution.

The Maximum Volume Increment capability is an exclusive feature of Micromeritics gas adsorption instruments.