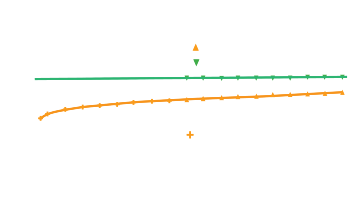

By 2050 almost 50% of the CO2, reductions come from technologies that are currently at the demonstration or prototype phase

Micromeritics products will play a key role in the development of Adsorbents, Membranes, and Catalysts critical for technology development.

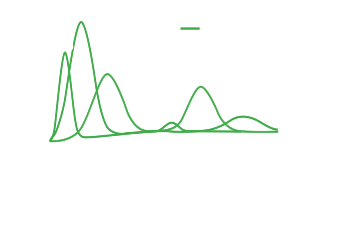

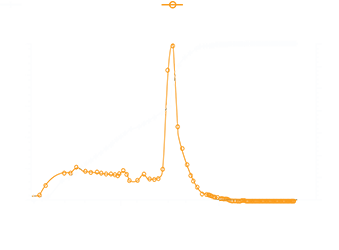

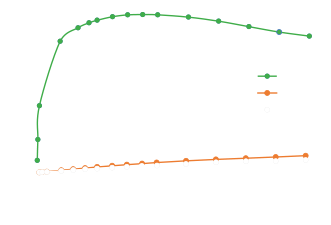

Surface area by gas adsorption including BET surface area

Micromeritics offers the most comprehensive portfolio of high-performance instruments

to characterize the materials required to achieve a more sustainable future