We offer high-performance chemisorption analyzers, supported by expert application scientists, for evaluating surface active sites, adsorption strength, and the reactivity of powders and particulate materials.

Chemisorption, or chemical adsorption, is a surface phenomenon where a chemical reaction occurs between the adsorbate (gas or vapor) and the exposed surface of a solid material. This process results in the formation of a strong bond via electron sharing and valence bonding, creating a distinct chemical species at the surface. Unlike physical adsorption, chemisorption is highly specific, involving the splitting of adsorbing gas or vapor molecules into atoms, radicals, or ions that chemically bond to specific adsorption sites on the surface.

This interaction is typically characterized by a high binding energy and is irreversible under standard conditions. Chemisorption plays a vital role in catalyst characterization, providing key insights into properties such as the reduction temperature at which metals become catalytically active, the quantity of surface metal or active species available for reaction, the strength of specific active sites, and the material’s performance after undergoing reduction or oxidation cycles.

In dynamic chemisorption, the identity, quantity, and strength of active sites can be quantified by adsorption, desorption, or reaction under isothermal or temperature programmed conditions. Dynamic chemisorption utilizes a variety of techniques such as temperature programmed reduction (TPR), oxidation (TPO), desorption (PTD), and pulse chemisorption to characterize active sites in materials.

For the dynamic system, depending on the experiment, a lower concentration of active gas may be in contact with the sample for only a few seconds. Depending on the sample, equilibration and access of the active gas to the adsorption sites of interest may be faster in the static system.

Automated chemisorption analyzer for essential catalyst characterization measurements

The premier instrument for dynamic chemisorption of heterogenous catalysts by pulse chemisorption and temperature-programmed reactions (TPR, TPD, TPSR, TPO).

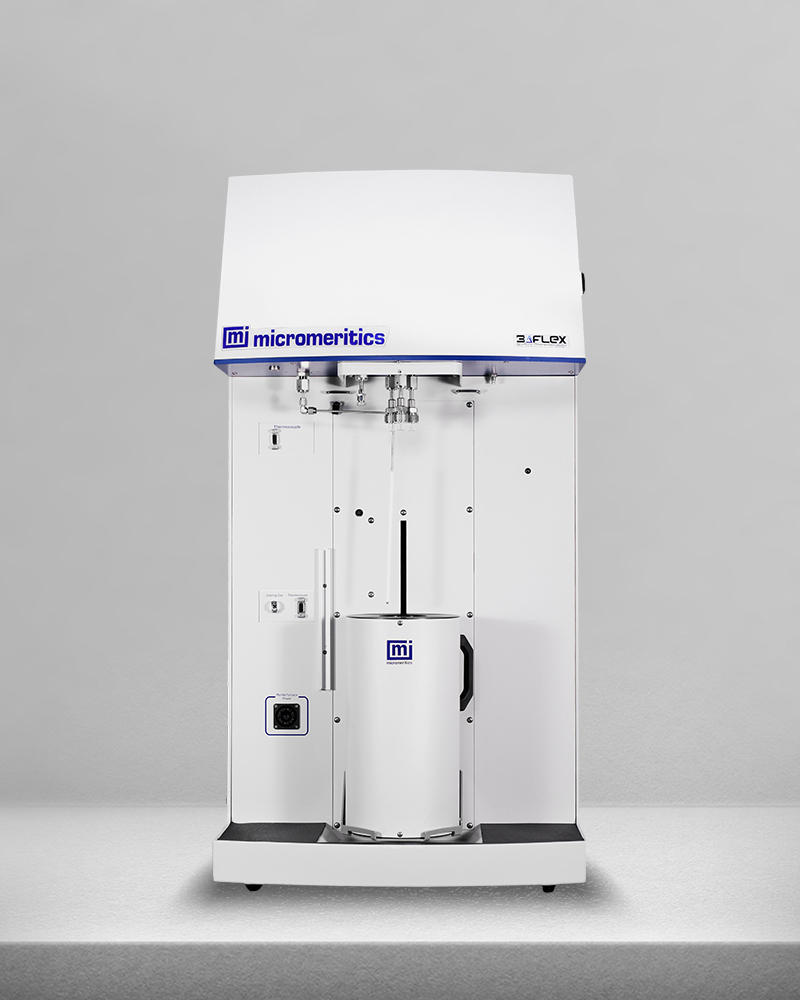

Static and dynamic chemisorption combined with the most advanced high-vacuum gas adsorption measurements for complete surface characterization of porous materials.

End-to-end surface characterization from sample prep to physical and chemical adsorption measurements.

Perform in situ measurements of catalyst characteristics by integrating the ICCS with a flow reactor system

De-risk new catalyst and process scale-up by demonstrating and optimizing performance under process conditions in an automated benchtop flow reactor.

High-throughput static chemisorption for reliable screening and process control

We provide a comprehensive range of characterization services whether it is the analysis of a single sample, a complex method development or validation, new product assessments, or addressing large-scale manufacturing projects.