The density of a material is defined as its mass divided by its volume. The bulk density of powdered and granular materials is often measured by the “tap” density method1. A material’s tap density is obtained by filling a container of known volume with a known mass of sample and vibrating it. This value is com-monly referred to as “tap” density because it is typically obtained using a mechanical device that alter-nately lifts and drops the container a specified number of times, producing a loud tapping noise.

Because this measurement varies depending on the vigor and number of taps, tap density is not an inherent property of a material. It is nevertheless a measurement of considerable interest in packaging, handling, and shipping bulk granular products.

The GeoPyc® Method for Determining “Tap” Density

Micromeritics’ GeoPyc 1360 T.A.P.™ Density Analyzer accomplishes essentially the same measurement as a tap density device, but it operates in an entirely different manner and can provide additional information. Analysis with the GeoPyc is quick, easy, automatic, and essentially noiseless.

To determine a powdered or granular material’s T.A.P. density, a quantity of sample is placed in a sample chamber, and a plunger is inserted into the chamber. The chamber and plunger are mounted on the analyzer, then automatic analysis is started. To start an analysis, the operator enters data using the instru-ment’s keypad, following a short series of prompts on the Liquid Crystal Display (LCD) screen.

During analysis, the GeoPyc agitates the sample chamber. While the chamber is being agitated, the GeoPyc drives the plunger into the chamber until the desired consolidation (compression) force is achieved.

The GeoPyc allows you to specify the degree of consolidation as either force (in Newtons) or pressure (in Newtons/cm2). The GeoPyc’s sensitive force transducer and analog to digital converter ensure that the plunger exerts a highly consistent force upon the sample, analysis after analysis. This repeatability of compression force gives you precise control over sample consolidation.

The distance traveled by the plunger into the chamber containing the sample material is compared to the distance traveled by the plunger when the chamber was empty. (Empty chamber “blank” data are col-lected and stored in the instrument during initial setup.) When the same force value is used for both the blank and sample measurements, the difference between the two measurements can be used to calculate the bulk volume and the T.A.P. density of the sample.

The GeoPyc’s ability to control the consolidation force (the degree of compaction) gives you great flexi-bility in data assessment. For example, you may wish to correlate GeoPyc T.A.P. Density data with historical data you have collected using a traditional tap instrument. This can easily be done by specifying a compression force that corresponds to the number of taps used to collect past data*. Alternatively, measurements may be made over a range of force values to yield additional information about the sam-ple’s packing behavior and compaction at higher pressures.

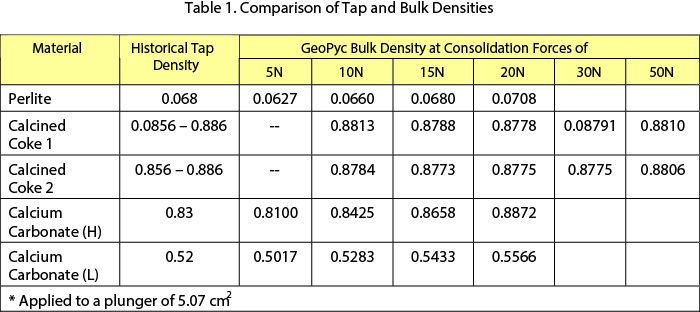

As is to be expected, bulk densities generally increase as the consolidation force increases. GeoPyc T.A.P. densities (as shown in Table 1) typically replicate tap densities between consolidation forces of 5 to 15N, when applied through a plunger of 5.07 cm2 cross section ( ie: consolidation of 1 to 3N/cm2). The GeoPyc determines the sample’s volume at the desired degree of compression, then the sample’s weight is used to calculate its bulk density.

*Instructions for determining the compression force that corresponds to the degree of packing achieved by another method can be found in Application Note Number 107, Determining the Force or Pressure to Use for T.A.P. Density with the GeoPyc 1360

1 ASTM Standard Test Method B 527-81, Tap Density of Powders of Refractory Metals and Compounds by Tap-Pak Volumeter.