Conventional tap density analyzers obtain the volume of a material by lifting and dropping a graduated cylinder multiple times until the sample bed no longer compacts. This is a loud process that requires an operator to estimate the level on a graduated cylinder to the nearest tenth milliliter.

The GeoPyc emulates conventional tap density analyzers by applying a consistent force across a sample bed, while a chamber rotates. This process is quieter, faster, and yields higher repeatability. Transverse Axial Pressure (T.A.P.) refers to the manner in which the chamber rotates and agitates the sample while it is being compacted.

Emulating Tap Density

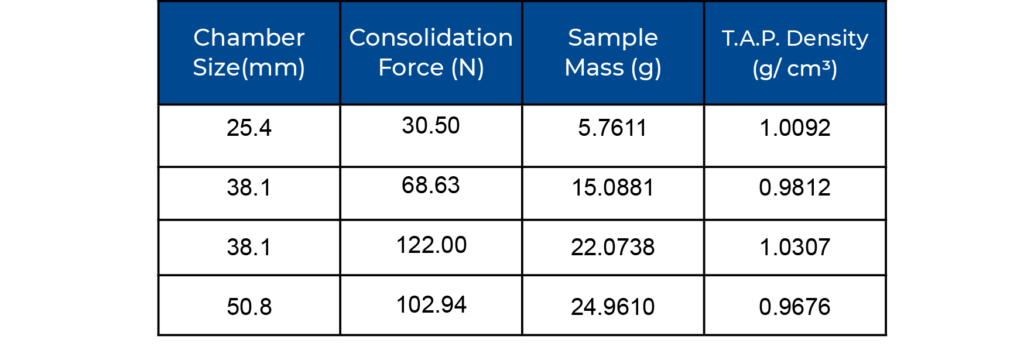

Lactose monohydrate, sucrose, talc, and titanium dioxide were analyzed on a conventional tap density analyzer to determine tap density. Each sample was analyzed five times to obtain an average. Results can be found in Image 1.

Parameters that must be determined to emulate values obtained with the conventional analyzers are chamber size, sample mass, preparation cycles, analysis cycles, and consolidation force.

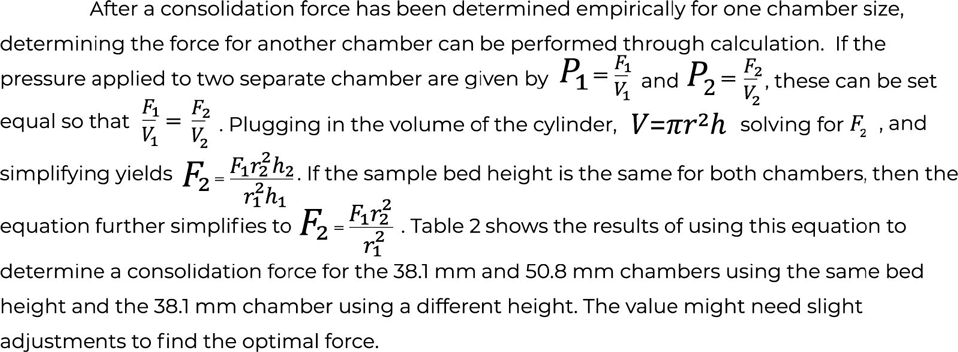

Three chamber sizes recommended for the T.A.P. measurements are 25.4 mm, 38.1 mm, and 50.8 mm. The 25.4 mm chamber was selected to minimize the needed sample quantity amount. Sample quantity was determined by filling the chamber to a height roughly equal to the chambers diameter. All subsequent runs used a similar mass. Two preparation and five analysis cycles were selected to provide a fast and repeatable analysis.

The consolidation force to be used is determined through trial and error. Analyses were performed using the previously mentioned conditions and varying the force until the T.A.P. density and the tap density results were similar. If the measured T.A.P. density value was higher than expected, then the consolidation force was reduced. Likewise, the consolidation force was increased if the T.A.P. density value was lower than expected.

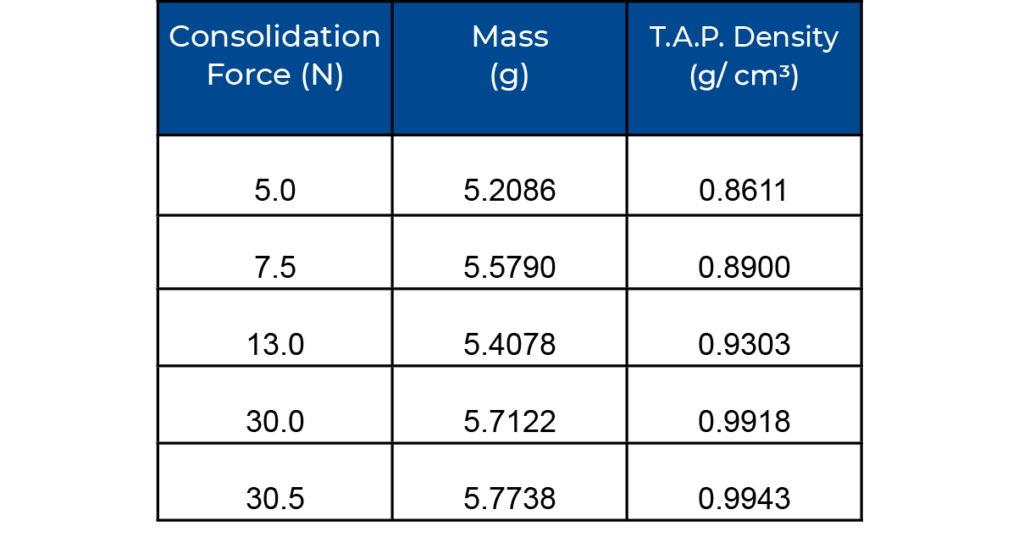

The consolidation force applied to talc powder was increased until the T.A.P. density value produced results equivalent to the conventional tap density analyzer. Table 1 shows the T.A.P. density values as a function of the consolidation force.

T.A.P. density results for lactose monohydrate, sucrose, talc, and titanium dioxide are shown in Image 1. The repeatability of these measurements are compared to the conventional method.

Length of Analysis

The conventional tap density analyzer performs five taps per second. The procedure is to perform a certain number of taps until the sample is no longer compacting. Initially, 10 taps are made, followed by 500 taps, and then 1250 taps until two consecutive readings are the equal.

The GeoPyc requires performing a blank analysis, with each T.A.P. density analysis, on the sample chamber to determine the number of steps a motor takes to push a plunger to the bottom of the sample chamber. After a consolidation force has been determined, the blank can be performed separately to reduce analysis time. The analysis time for the tests performed within this experiment was between three to four minutes each.

Conclusion

The T.A.P. density is a fast, quiet, analysis that is easy to perform. Results are more repeatable

than those acquired through conventional tap density measurements.