A full range of process conditions

A system that is quick to deploy and simple to use

De-risk your scale-up and shorten your development schedule with the FR system that matches your process.

Interchangeable reactors

Six Gas Inlets

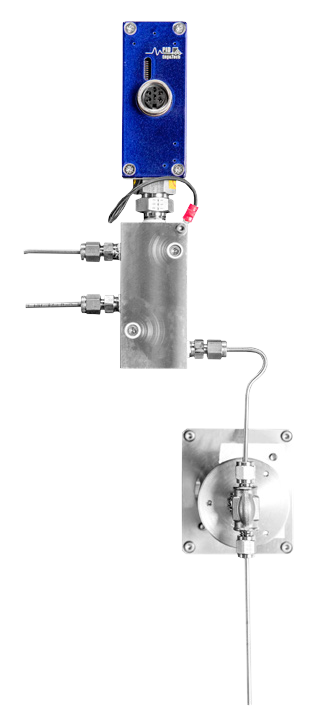

Patented pressure-control valve provides stable control with a unique combination of wide dynamic range, high resolution, and ultra-low dead volume for any stream type.

The FR includes multiple levels of safety features that make the system simple to deploy and safe to operate. Additional safety features such as automatic shut-off valves and gas detectors are available to add as appropriate.

Up to six total gas inlets, each coupled with a high-precision mass flow controller.

HPLC pump with integrated Coriolis mass flow meter provides precise, stable feed control.

Additional capabilities include syringe pumps for low flow rates and temperature control up to 80°C for heavy liquids.

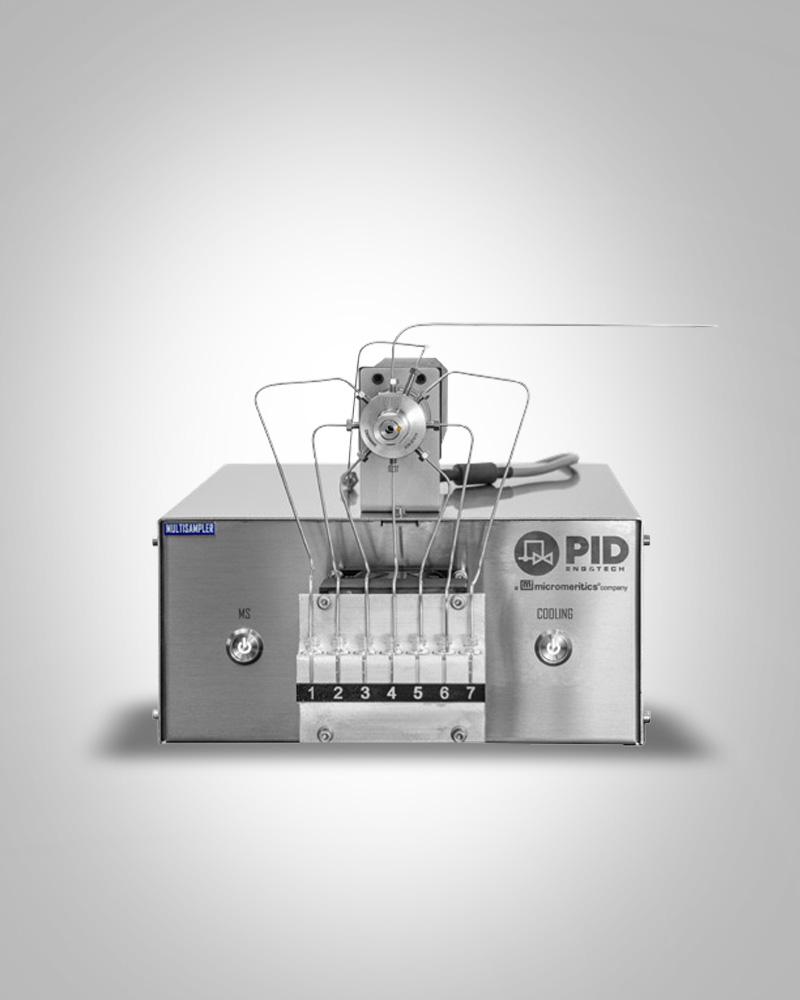

Automatic programmable liquid multisampler to collect up to seven liquid samples, including cooling to stabilize volatiles

Measures outlet mass flow rates to determine reaction mass balance.

Measures and records outlet liquid to determine reactor mass balance and liquid phase yield.

Measures and records outlet liquid to determine reactor mass balance and liquid phase yield.

The FR-200 includes all the capabilities of the FR-100 with two independently-controlled reactors. Three available configurations of the FR-200 enable reactor flows of increasing complexity to mimic even the most intricate reactor process flows.

Due to its high throughput testing capabilities the highly versatile computer-controlled Micromeritics Multi Catalyst Reactor (MR) series enables scientists to accelerate catalyst research: The Micromeritics MR 4 or MR 8 evaluation units provide capabilities to investigate 120 kinetic data points per week. Researchers can comprehensively measure the activity and selectivity of heterogenous catalysts for screening and kinetic studies.

The automated MR 4 and MR 8 provide operational flexibility for determining optimal reaction conditions and understanding operational challenges for a wide range of applications. Due to the units’ high level of flexibility and gas or optional liquids feeding systems, the MR 4 or MR 8 can be configured to individual application needs: reaction and regeneration, for example, can be carried in-situ and at consecutive stages thanks to the precise temperature-control and feeding system.

The Micromeritics MR 4 or MR 8 are easily integrated with a range of analytics including chromatography and spectroscopy and are operated or monitored via a user-friendly software that makes experimental study definitions easy.

Catalyst Testing Rates of 120 Kinetic Data Points a Week Save Time and Resources During Screening

Key Features:

The high productivity catalyst evaluation units are available in multiple configurations:

MR 4 and MR 8 multi catalyst reactors support the following studies

Want to move beyond the capabilities of the FR-series? The Micromeritics custom reactor engineering team has more than 25 years experience developing high-performance custom reactors and small-scale pilot plots.

Example Processes

Liquid Hydrocarbons & Wax Liquid fuels and other chemical products can be...

+Synthesis/ Decomposition The Haber-Bosch process, is an artificial nitrogen fixation process and...

+And Higher Alcohols One route to produce methanol is characterized by the...

+Steam & Dry Steam methane reforming (SMR) is a process in which...

+Methane Production The Sabatier Process produces methane and water from a reaction...

+Hydrogenation is a chemical reaction between hydrogen and another compound, usually in...

+| FR-100 | FR-200 |

| Number of Reactors | 1 | 2 |

| Automatic High Pressure Liquid/Gas Separator | 1 Optional:1 |

Duo/Twin: 1 Parallel: 2 |

| Reactor | 800 ℃ SST 316 9.1 mmID |

800°C SST 316 9.1 mm ID |

| Pressure (bar) | Standard:100 Optional:200 |

Standard:100 Optional:200 |

| Gas Feed | Standard:3 Optional:6 |

Standard:Duo: 3; Twin/Parallel: 4 Optional:6 |

| Reactor Bypass | Automatic | Automatic |

| FR-100 | FR-200 |

| Number of Reactors | 1 | 2 |

| Automatic High Pressure Liquid/Gas Separator | 1 Optional:1 |

Duo/Twin: 1 Parallel: 2 |

| Reactor | 800 ℃ SST 316 9.1 mmID |

800°C SST 316 9.1 mm ID |

| Pressure (bar) | Standard:100 Optional:200 |

Standard:100 Optional:200 |

| Gas Feed | Standard:3 Optional:6 |

Standard:Duo: 3; Twin/Parallel: 4 Optional:6 |

| Reactor Bypass | Automatic | Automatic |

| Up/down flow selection valve | N/A |

| Wax Trap | 1 | 2 |

| Fluidized Bed Reactor | 1 | 1 |

| Liquid Multisampler | 2 | 4 |

| Additional Reactors | Quartz and special alloys 5, 13, 17, 23 mm ID |

Quartz and special alloys 5, 13, 17, 23 mm ID |

Provided specifications were valid as taken from available documents at time of publication. These specifications may change without notice and are only provided as a general reference

Request a quote or talk to an expert for more information

um über Produktneuheiten, Software-Updates und die neuesten wissenschaftlichen Ressourcen informiert zu bleiben

Urheberrecht © 2025 Micromeritics Instrument Corporation