Renewable and low carbon Hydrogen to contribute over 20% of global carbon abatement by 2050.

Micromeritics products will play a key role in the development of Adsorbents, Membranes, and Catalysts critical for technology development.

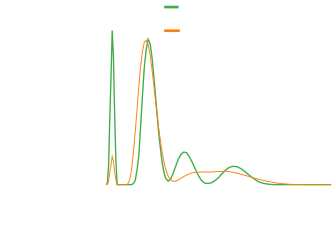

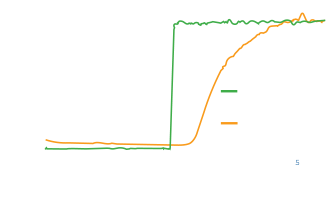

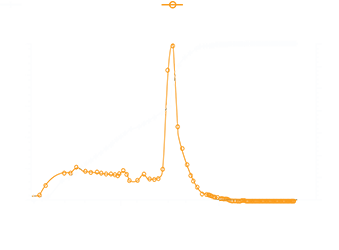

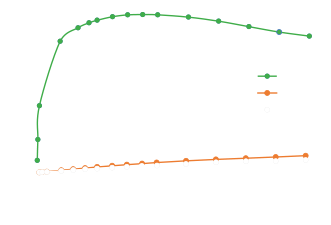

Surface area by gas adsorption including BET surface area

Micromeritics offers the most comprehensive portfolio of high-performance instruments

to characterize the materials required to achieve a more sustainable future

Hydrogen will play a key role in decarbonization as it supports 60% of the applications with greenhouse gas (GHG) emissions.