Many microporous materials (such as carbons, zeolites, and molecular sieves) retain helium in their pore structures after being exposed to helium. The helium penetrates deep into the pores and takes a long time to diffuse from the material.

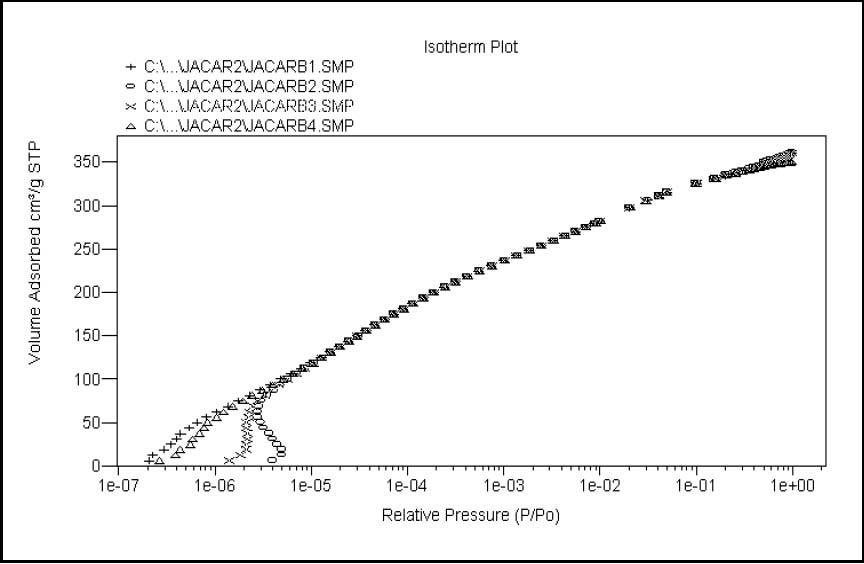

A study was performed in which analyses were performed on a microporous carbon cloth exhibiting typical helium retention. The isotherm examples in this application note show the effect of using different run conditions to eliminate or minimize the helium retention effect.

The following conditions were used in the analyses:

- Samples were degassed for five hours at 250 °C prior to analysis

- Nitrogen adsorptive at liquid nitrogen temperature

- Similar run conditions for all analyses

- Low pressure dosing (MicroDose) of 6 cm3/g STP

The samples shown are:

- JACARB1.SMP – Analyzed with entered free space (no exposure to helium prior to analysis)

- JACARB2.SMP – Free space measured with helium; evacuated without lowering Dewar after free space

- JACARB3.SMP – Free space measured with helium; evacuated for 30 minutes with Dewar lowered after free space

- JACARB4.SMP – Free space measured with helium; evacuated for five hours with Dewar lowered after free space

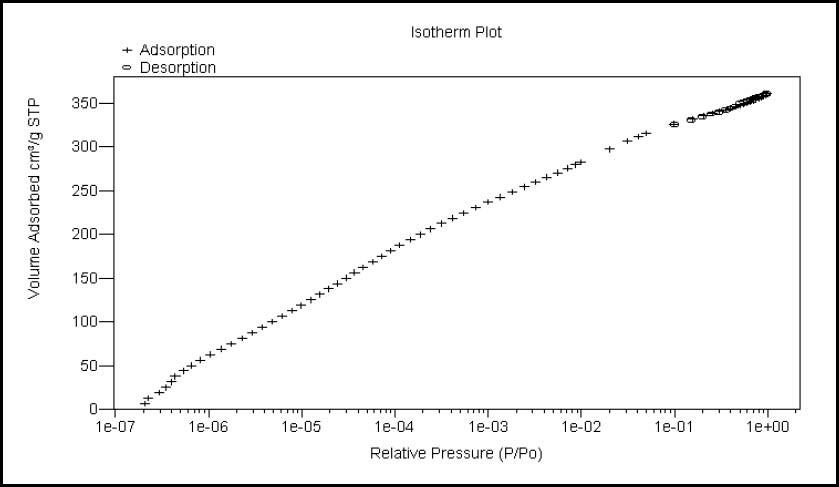

The isotherm of this figure was obtained after degassing the sample and using an entered free space. Therefore, there was no exposure to helium prior to the analysis. As can be seen, the first 6 cm3/g MicroDose equilibrated at a pressure in the 10-7 P/Po range. Since there was no exposure to helium prior to the analysis, the analysis proceeded normally and provided excellent low pressure data.

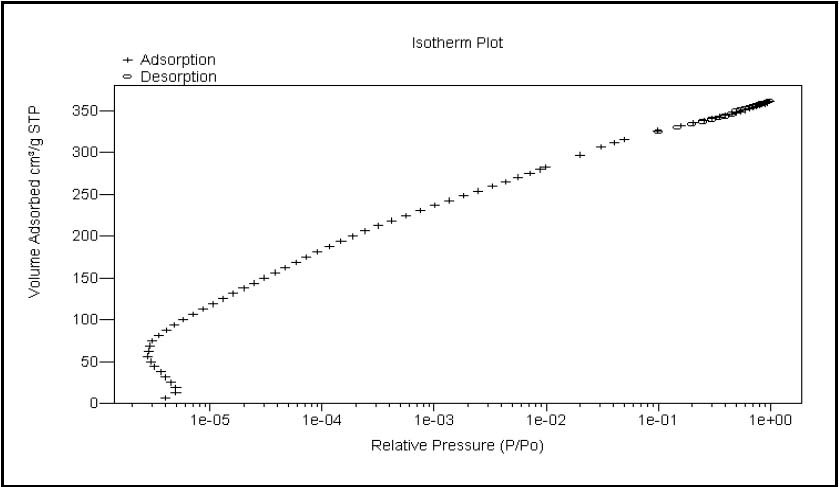

This isotherm is the result of an analysis in which free space was measured. The sample was evacuated after the free-space measurement but the Dewar was not lowered. It is to be noted that helium diffusing from the sample raised the pressure at which the first three points equilibrated. For the next six points, the helium diffusing from the sample became less and less. After about 12 points, the points rejoined the actual isotherm and were no longer influenced by any residual helium.

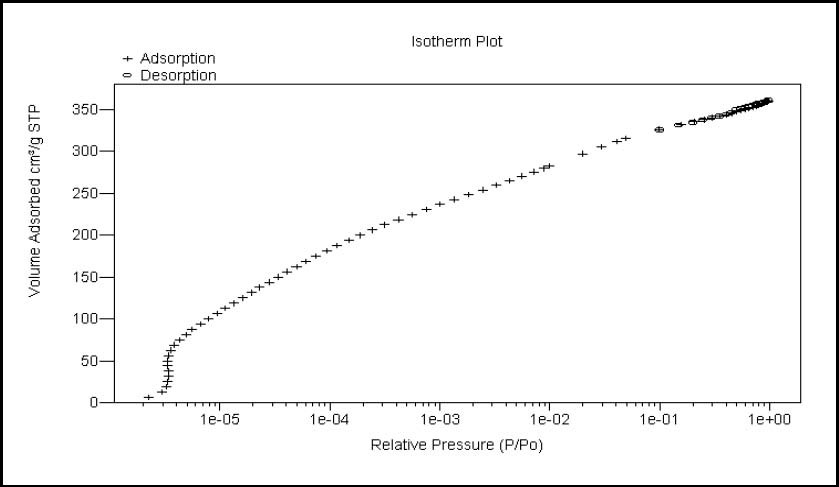

This isotherm was collected after the sample was exposed to helium during free-space measurement. The sample was evacuated for 30 minutes and then the Dewar was lowered. As seen, the 30-minute evacuation time was insufficient to remove completely the helium from the sample structure. The first MicroDose again was 6 cm3/g, but the first point equilibrated in the 10-6 P/Po range, a higher pressure than the first equilibrated dose in the JACARB1 analysis.

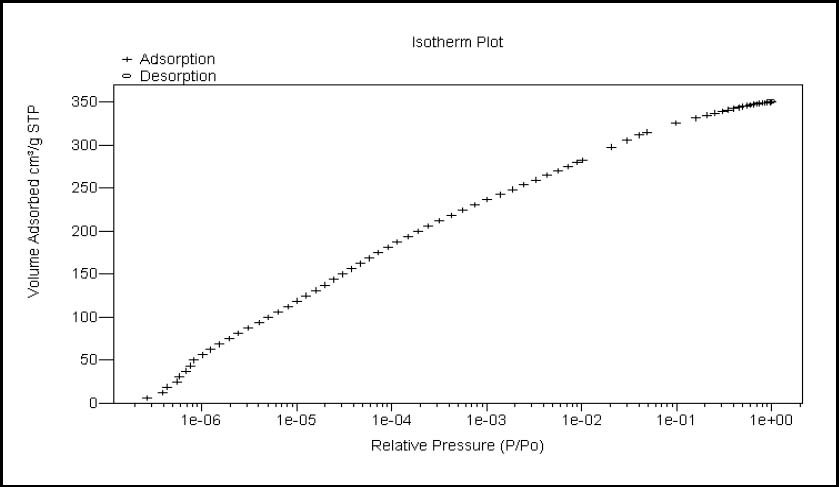

This isotherm was obtained after the sample was analyzed with a measured free space. However, this time the Dewar was lowered after the free-space measurement and an evacuation of five hours. The first MicroDose of 6 cm3/g equilibrated in the 10-7 range just as the sample in Figure 1 (not exposed to helium). This isotherm is still slightly influenced by a small diffusion of helium from the sample. After only about six points, the partial pressure contributed by the helium became insignificant and the equilibrated points rejoined the normal isotherm.

This figure shows all isotherms overlaid for comparison. It is clear that the isotherms collected after exposure of the sample to helium are adversely influenced by the small partial pressure contributed by the helium diffusing from the sample in the low pressure range. This interference can be eliminated entirely by using the Entered Free Space feature of the ASAP software to avoid any exposure of the sample to helium. It also can be seen that progressively longer evacuation times after helium exposure reduce the amount of helium remaining in the sample. But even after five hours of evacuation at room temperature, there is still a slight interference from the helium. The lowest pressure points are in the 0.1 mmHg range, so it takes little pressure contribution from helium to adversely influence the equilibrated pressures.

In conclusion, avoiding all exposure of microporous samples to helium is the best way for countering the adverse effects of helium diffusion. Using the Entered Free Space option* of the ASAP software results in faster analysis times, since no time is lost attempting to evacuate the helium after free-space measurement. This feature also is simple to use, convenient, and highly effective.

* Refer to Application Note No. 104 for information on how to minimize helium effects when performing analyses on microporous materials.