Micromeritics’ GeoPyc 1360 T.A.P.TM Density Analyzer accomplishes essentially the same measurement as a noisy, vibrating tap density device, but it operates in an entirely different manner. It also can provide additional information. Analysis with the GeoPyc is quick, easy, automatic, and quiet.

To determine the T.A.P. density of a powdered or granular material, sample is placed into the sample chamber, and a plunger inserted into the chamber. The chamber and plunger are mounted on the analyzer. All you have to do then is simply start the analysis. During analysis, the sample chamber is agitated and the plunger driven into the chamber until a preprogrammed consolidation (compression) force is achieved. The GeoPyc allows you to specify the degree of consolidation as either force (in Newtons) or pressure (in Newtons/cm2). The GeoPyc’s sensitive force transducer and analog-to-digital converter ensure that the plunger exerts a reproducible and consistent force upon the sample, analysis after analysis. This repeatability of compression force yields precise instrument control over sample consolidation.

The distance traveled by the plunger into the chamber containing the sample material is compared to the distance traveled by the plunger when the chamber was empty. Empty chamber “blank” data are collected and stored in the instrument during the initial setup. When the same sample force is used for the blank and sample measurements, the difference between the two measurements is used to calculate the bulk volume and the T.A.P. density of the sample.

The T.A.P. density of any material is not an intrinsic property of that material and certainly depends to a great extent upon that material’s particle size distribution and shape, as well as other factors inclusive of the geometry of the sample cell. Moreover, the T.A.P. density (or the related packing volume) cannot be predicted for a mixture of powders even when the T.A.P. density of the individual constituents is known. To demonstrate this, a synthetic hot chocolate mixture was simulated by mixing various quantities of granular sugar, powdered milk, and cocoa powder.

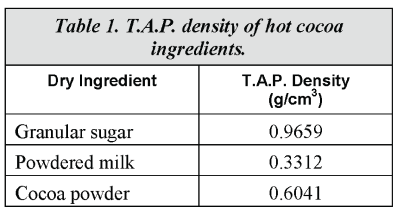

The measured T.A.P. densities of the three individual ingredients are shown in Table 1. All measurements were carried out using a force of 5 Newtons applied to a plunger of 5.07 cm2.

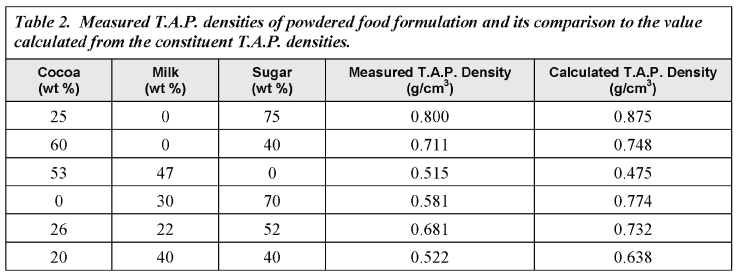

Six artificial formulations were then produced by gently rolling on a cloth (known as a blend cloth) in alternating, perpendicular directions. The T.A.P. density of each of these artificial mixtures was measured with the GeoPyc 1360. Again a compression force of 5 Newtons was applied to a plunger of 5.07 cm3 . In addition, a theoretical T.A.P. density was calculated using a simple linear model. The measured values and calculated values are shown in Table 2 for the six different mixtures produced.

As shown in Table 2, the packing volume, or the T.A.P. density, of any dry powder mixture cannot be calculated using any simple model of component properties. The problem is definitely nonlinear and cannot be simulated. In all but one instance above, the measured packing volume of that formulation was considerably greater than that predicted by a simple mass-weighted arithmetic average of the component values. The GeoPyc 1360 offers a simple and highly reproducible method for quickly quantifying an important but hard-to-measure quantity. Simple tap density devices suffer from segregation of components of differing densities and are prone to various operator subjectivity.