Our world leading analytical equipment offers high performing solutions to improve your advanced battery’s safety, energy & power density, and cycle life

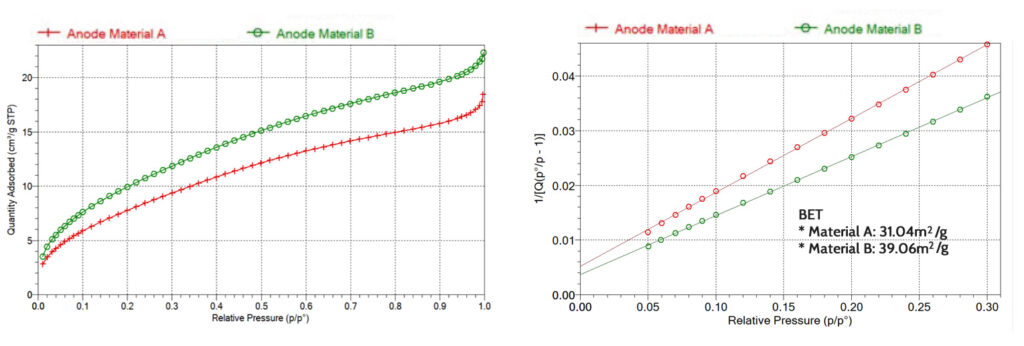

Surface area by gas adsorption including BET surface area

Lithium-ion (Li-ion) batteries are an advanced battery technology which have four major components: anode, cathode, separator, and electrolyte.

At Micromeritics we have instrumentation for all stages of battery production starting from the raw material precursors to the final battery cell.

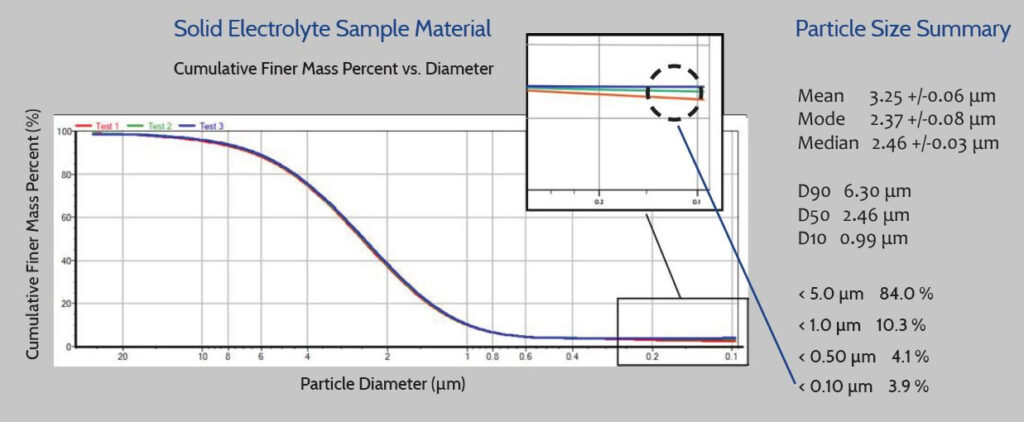

In the future the liquid electrolyte may be replaced by a solid electrolyte for improved safety and performance.

Micromeritics best-in-class material characterization instrumentation in our core areas of expertise.

Our extensive range of gas adsorption analyzers offer convenient solutions to realize your R&D, quality control, and manufacturing needs.

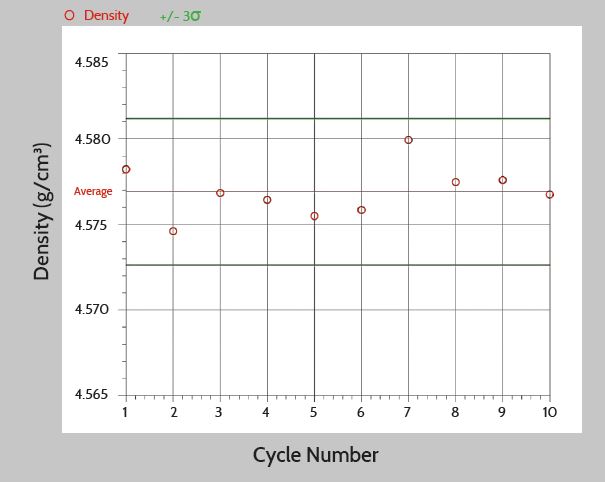

The AccuPyc uses Gas Pycnometry and the GeoPyc uses a unique displacement technique to determine the:

Combining data from these two techniques enables the determination of the percent porosity and total pore volume

Data Summary

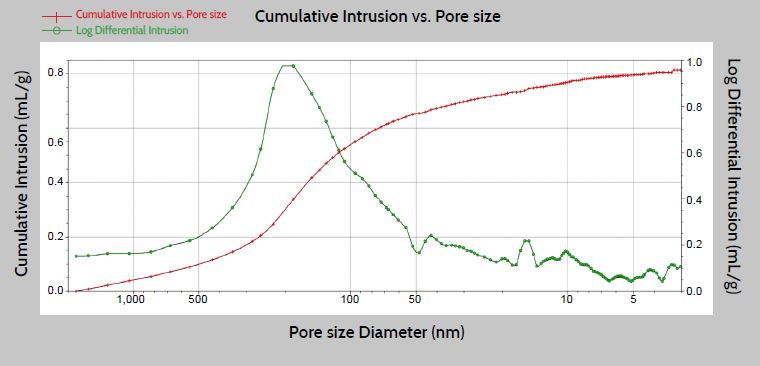

Mercury porosimetry is a uniquely valuable technique which delivers speed, accuracy and the comprehensive characterization of many sample properties:

Our extensive range of gas adsorption analyzers offer convenient solutions to realize your R&D, quality control, and manufacturing needs.

Data Summary

The SediGraph remains the global standard for particle size analysis by sedimentation after five decades, whether in a rugged production environment or a controlled laboratory setting.

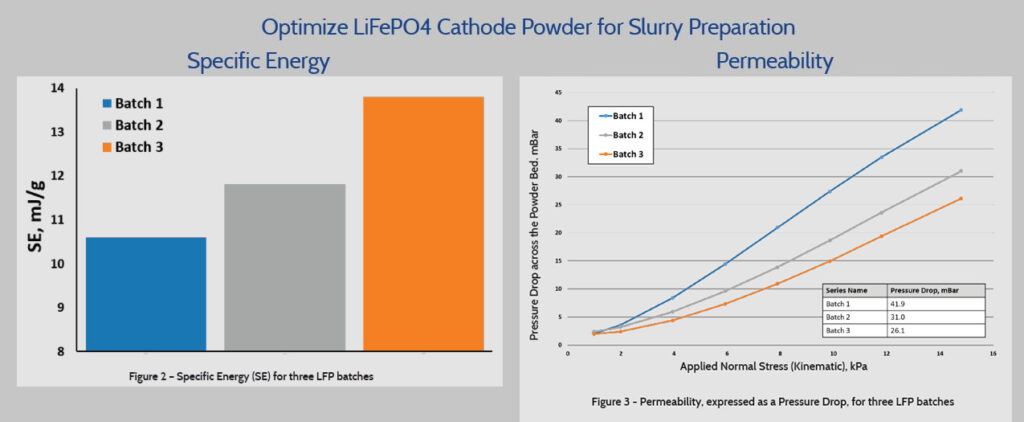

The FT4 provides comprehensive flow property characterization of a powder and is now established as a universal powder tester. Optimize manufacturing processes by quantifying a powder’s.