The mass of an object divided by its volume is its density (g/cm3). The result is called the envelope density (sometimes the bulk density) when the object’s volume is determined as if a thin film surrounded it and blocked access to pores in the object. When all pores are open and freely accessible so that they can be excluded from the volume measurement, the result is termed the absolute density (sometimes the skeletal, true, or real density). The two densities are equal when the object is nonporous but they are different when the object is porous. Micromeritics’ GeoPyc® 1360 measures envelope density. The Micromeritics AccuPycTM 1330 measures absolute density.

The GeoPyc determines the volumetric displacement of a free flowing, dry medium composed of small, rigid spheres — called DryFlo® — by the object being tested. DryFlo® conforms to external features but does not penetrate pores, making it possible to analyze irregularly-shaped samples and samples comprised of multiple pieces (as small as 2 mm).

The use of a dry medium makes the method different from other current procedures. The first of these other procedures, designated Method A1 , seals off the pores in a porous object by dipping the object in molten wax. The envelope density is then calculated from the sample dry weight, the wax-coated weight in air, and the wax-coated weight suspended in water. The second, designated Method B2 , submerges the test object in a pool of mercury and measures the displaced mercury volume. Mercury, being a non-wetting liquid, does not enter into pores under low pressures. Method C3 does not seal off the pores but instead seeks their volume. It requires the object to be dried thoroughly, weighed, boiled in water to remove air from the pores, cooled in water to fill the pores, and then superficially dried. The difference in object weight when dry and when the pores are filled permits calculating the volume of the pores and, from that and the absolute density, the envelope density.

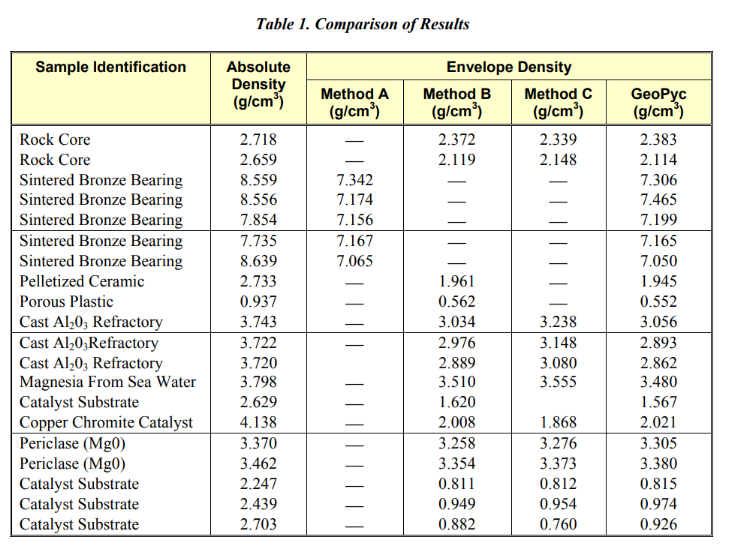

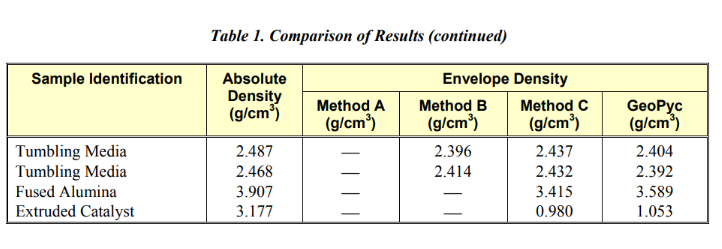

Table 1 demonstrates that the GeoPyc yields comparable results to those obtained by the other methods. The GeoPyc method, however, differs from the others in several ways:

- Speed. While Methods A and C can take hours to perform, the GeoPyc can complete an analysis in 5 to 20 minutes, depending on operator-selected variables. This facilitates more frequent sample testing and greater responsiveness of production to quality standards.

- Automation. Because the GeoPyc’s method is automated, it reduces the likelihood of human error. The GeoPyc requires no difficult or specialized technique, unlike Method A, in which the operator must avoid allowing the molten wax to enter the pores, or Method C, in which the operator must not empty the pores by over-drying.

- Non-toxic/Non-destructive. Because DryFlo is non-toxic and easily brushes off most surfaces, samples are generally not altered by GeoPyc analysis. They can often be used for further testing or even returned into production. Unlike Method B, the GeoPyc requires no handling or disposal of hazardous materials.

Comparable Results

The following table presents accumulated data from methods A, B, and C for comparison with GeoPyc values. The GeoPyc data and the absolute densities were determined by Micromeritics using the GeoPyc 1360 and the AccuPyc 1330. Some of the remaining values were measured by Micromeritics and some were obtained from other sources. Blanks in the table indicate test data were unavailable.

General agreement among results in the table is evident despite the very different techniques involved and the different levels of operator expertise required. When the data from the other methods are ratioed to GeoPyc values, the resulting numbers spread from 1.005 to 0.961 for Method A, from 1.034 to 0.959 for Method B, and from 1.088 to 0.821 for Method C. When all ratios are included and their average deviations are summed, overall agreement with the GeoPyc is within 0.17% for Method A, 0.07% for Method B, and 0.79% for Method C.

Recursos

- DIN 30911 (German) which is essentially the same as ASTM Standard C914-89, Bulk Density and Volume of Solid Refractories by Wax Immersion.

- ASTM Standard Test Method C493-93, Bulk Density and Porosity of Granular Refractory Materials by Mercury Displacement.

- ASTM Standard Test Method C20-92, Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water.