Improving competitiveness in the industry is sharply marked by developing new products with high quality features and a high added value. Continuous and automatic pilot plants that can simulate industrial processes at the laboratory level with reasonable scalability are essential for seeking new products, improving the quality of existing ones and developing new processes.

These systems high degree of complexity, their high number of operating variables and the interrelationship among them requires an exhaustive study of the instrumentation and control in order to attain results provided by these systems that are representative and reproducible.

Due to the renewed interest in innovative ways to convert the existing fuel reserves with improved technologies such as gasification and pyrolysis, PID Eng&Tech has worked in collaboration with important researchers in the field of biofuels in order to develop the most versatile pilot plant existing in the market nowadays. Its versatility and complete automatization, allows determining optimal experimental conditions and detecting possible operational problems in industrial gasification or pyrolysis reactors.

You can choose processing up to 2 kg/h of solid for gasification and pyrolysis processes or smaller scale up to 200 g/h.

The screw reactor unit allows for obtaining add-value solid from waste by means of a slow pyrolysis process. It can treat different types of feedstock under a wide range of temperature conditions. It comprises a SS310 screw driven horizontal tubular reactor housed in a multi-zone furnace, which allows operation with temperature ramps throughout all reactor length. The residence time in the reactor can be fixed from few minutes up to hours. Thanks to an independent dosing screw system, the feed rate can be modified independently from the residence time. At reactor outlet, the solid product is collected in a vessel, whereas the obtained gas leaves the vessel through the top, where a filtering element is fixed to prevent fine particles withdrawal.

Finally, the vapors are condensed to obtain liquid, and gas product is measured in a wet gas meter. A vacuum pump is used to avoid plugs in the reactor and keep the pressure in the system constant.

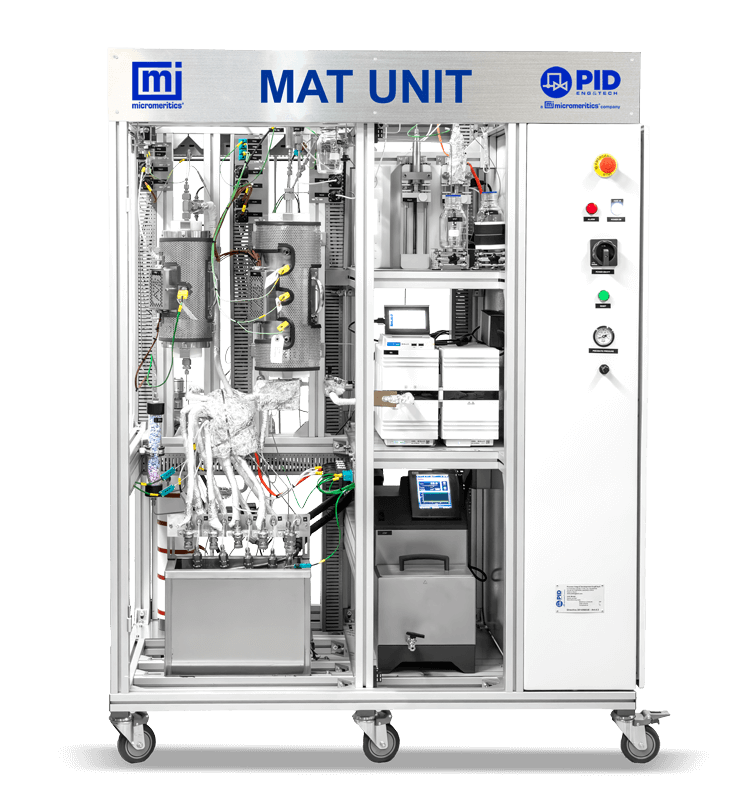

Fully automatic, controlled and computerized laboratory reactor for the analysis of Fluid Catalytic Cracking (FCC), using as feedstock petroleum oils or renewable sources such as bio-oil.

With an excellent reaction temperature control and making use of a precise syringe pump for gasoil feeding, even for a very short reaction time, this unit carries out reaction and regeneration in-situ and consecutives stages, including coke quantification. The four liquid products obtained are collected in a cooled receiver until the end of the experiments while gases can be analyzed online in a gas chromatograph.

This computerized and automatic pilot plant is based on a stirred tank reactor for operation in continuous, batch or semi-batch mode. The plant is high pressure certified according to current regulations and customer can design his own pilot plant by using as many options as required.

Computed and totally automatized unit based on photocatalytic reactor with one/two sight ports with capability to work at high pressure and temperature.

Our engineering team specializes in the design and construction of customized pilot plants. Our primary goal is customer satisfaction, which we achieve by collaborating closely with our clients to transform process ideas into R&D equipment.

Through the utilization of pre-designed modular components, we significantly reduce two critical project factors: construction time and cost. Additionally, we incorporate the latest advancements in process control technology to ensure optimal efficiency.

Request a quote or talk to an expert for more information

to stay connected to product news, software updates, and the latest scientific resources

Copyright © 2025 Micromeritics Instrument Corporation