We have extensive experience of building bespoke catalyst screening units for industrial and academic customers, from tailored analytical units through to complete pilot plants.

As the world’s leading supplier of high-performance characterization technology for powders and porous materials, Micromeritics empowers scientists in catalyst development and screening to save time and resources. Our precise and reliable measurements of porosity and surface properties predict performance, demonstrate functionality and accelerate candidate selection while mitigating risk .

Heterogeneous catalysis are employed in over 90% of industrial chemical syntheses and environmental controls. The success of a catalyst depends heavily on it surface morphology and reactivity.

Trusted by leading scientists and innovative companies worldwide, our technology enhances development speed, quality control,, and performance optimization performance for energy efficiency, process yield, and catalyst lifetime.

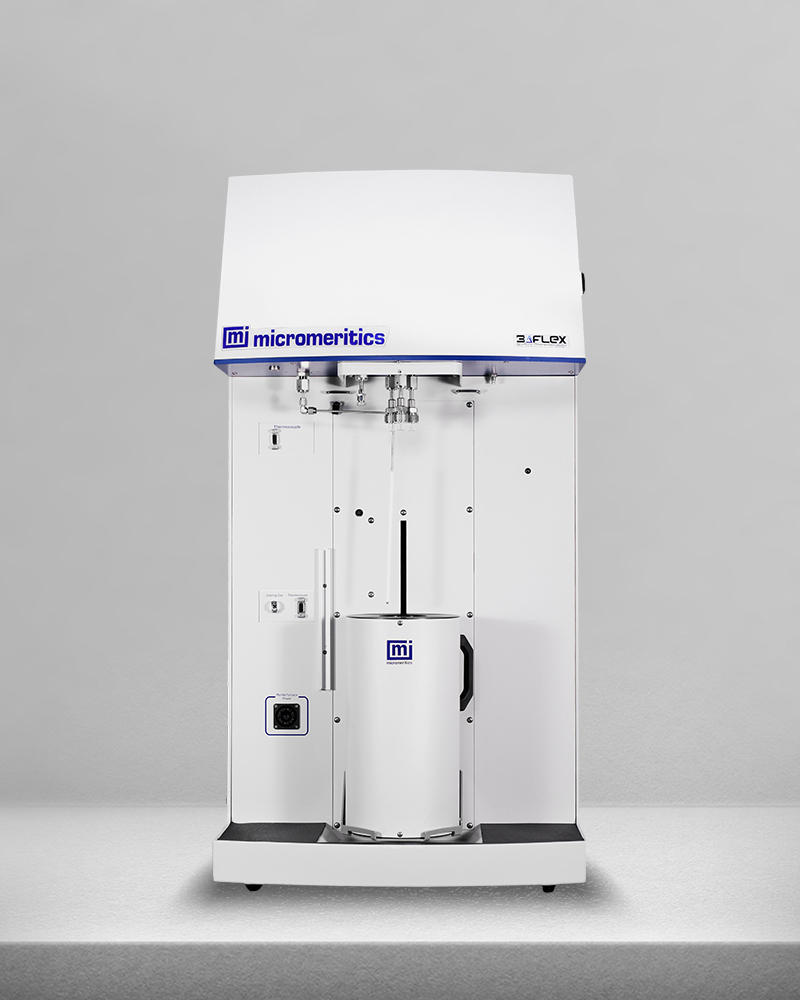

High-throughput analysis of surface area and porosity especially for mesoporous materials

Fastest measurement of surface area and gas adsorption isotherms due to unique differential measurement design

On-demand parallel analysis of basic to advanced morphology from micro- to mesoporous materials

Surface and pore morphology and structure determination from meso- to macropore size range

Turn-key bench-top flow reactors are quick to deploy, offer complete process control automation and recording, and enable reaction process studies under relevant conditions of composition, flow rates, pressure, and time-on-stream

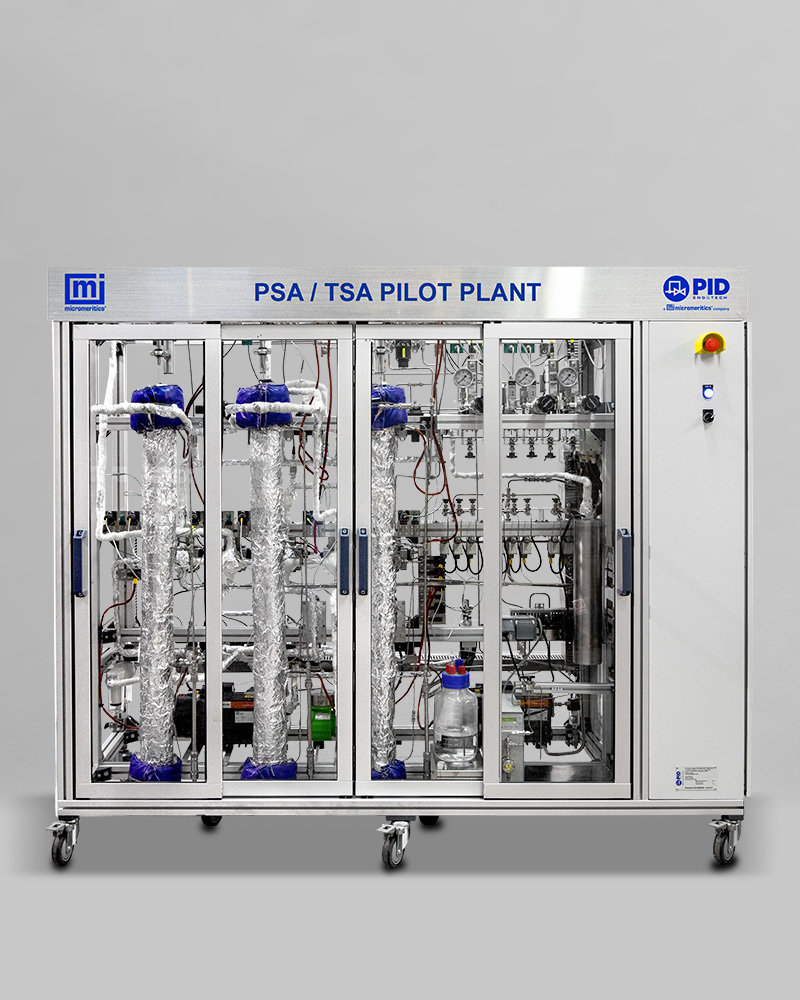

Customized lab-scale pilot plants de-risk scale-up by replicating complete process flows with moderate reactant quantities to validate and optimize new catalysts, processes and conditions.

We provide a comprehensive range of characterization services whether it is the analysis of a single sample, a complex method development or validation, new product assessments, or addressing large-scale manufacturing projects.

to stay connected to product news, software updates, and the latest scientific resources

Copyright © 2025 Micromeritics Instrument Corporation